Height measuring device and method of hydraulic bracket

A technology of height measurement device and hydraulic support, which is applied in measurement device, height/level measurement, surveying and navigation, etc., can solve the problems of affecting the measurement value, the device cannot work normally, and the influence of temperature change is large, so as to increase the adaptability and ease of use, easy installation, debugging and maintenance, and ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

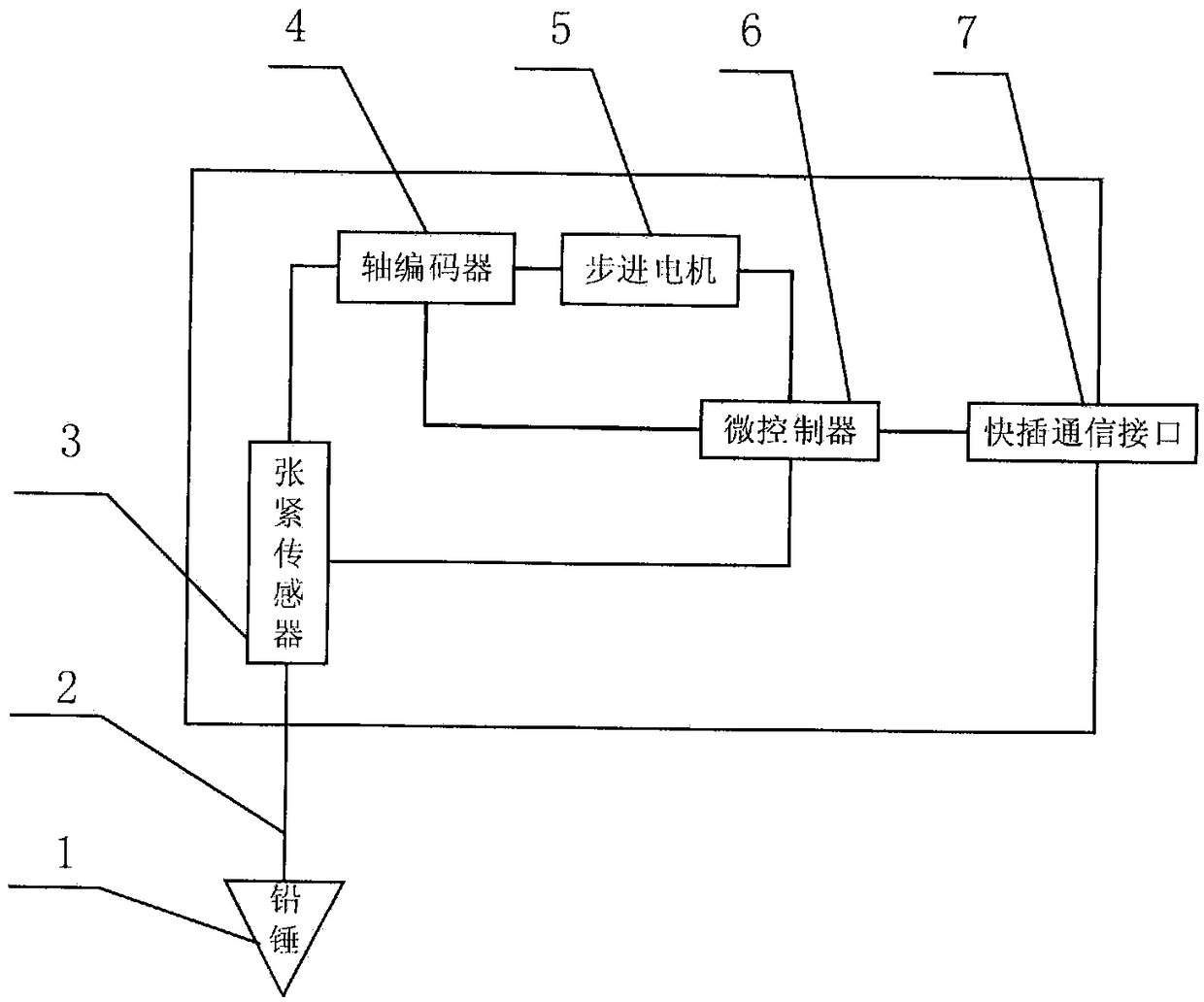

[0031] attached figure 1 A hydraulic support height measuring device according to an embodiment of the present invention is shown.

[0032] The height measuring device includes: a plumb weight 1, a height measuring pull rope 2, a tension sensor 3, a shaft encoder 4, a stepping motor 5, a microcontroller 6 and a quick-plug communication interface 7. Wherein the tension sensor 3, the shaft encoder 4, the stepping motor 5, and the microcontroller 6 are all located in the device housing, and the device is hoisted below the top beam of the hydraulic support. One end of the height-measuring stay cord 2 is connected to a stepper motor, which is controlled by different directions of rotation of the stepper motor to tighten or relax.

[0033] During the non-working state, most of the height-measuring stay cord 2 is also accommodated in the device housing. Under the action of gravity of the plumb weight 1, the other end of the height measuring stay rope 2 is located outside the height...

Embodiment 2

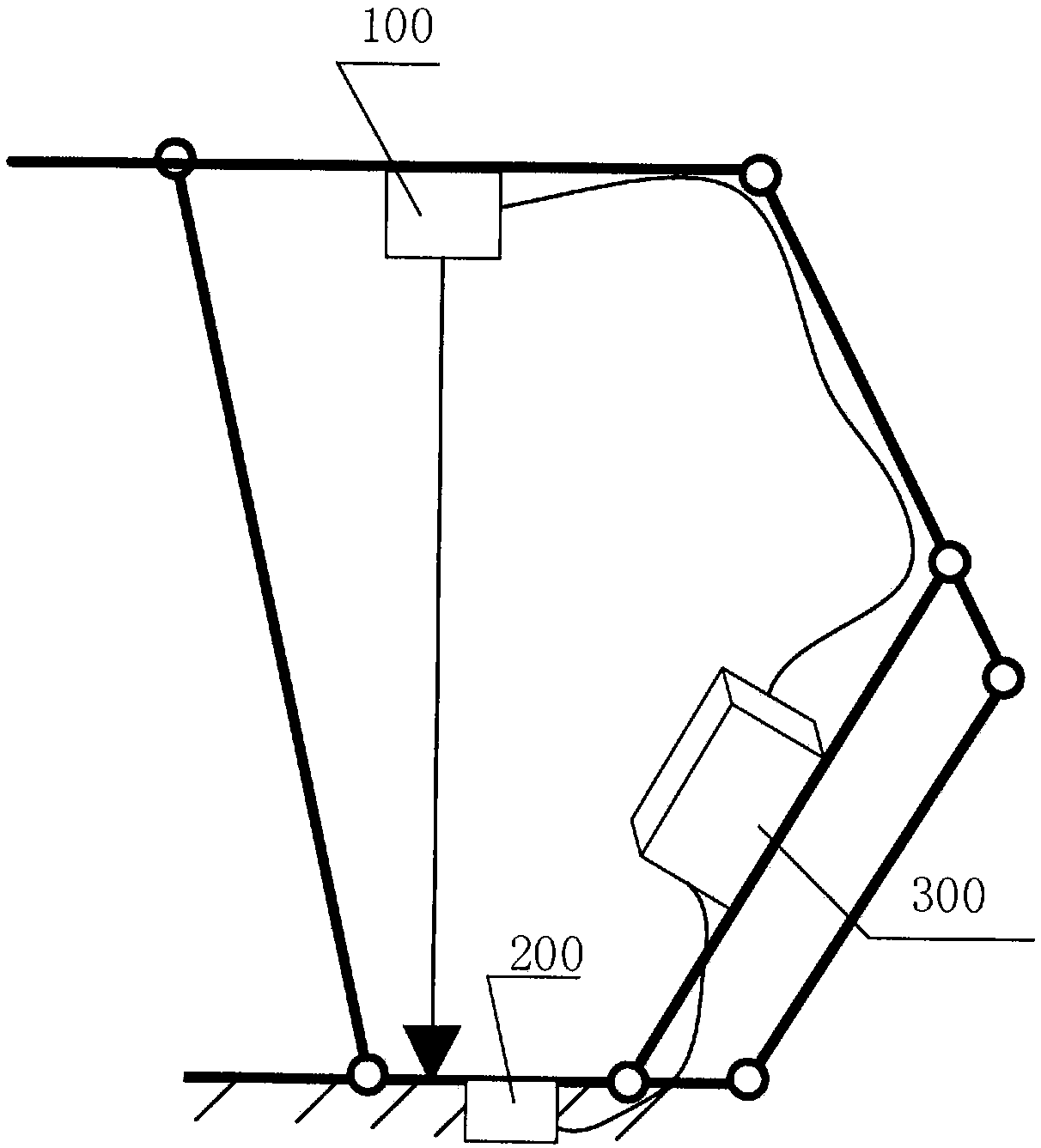

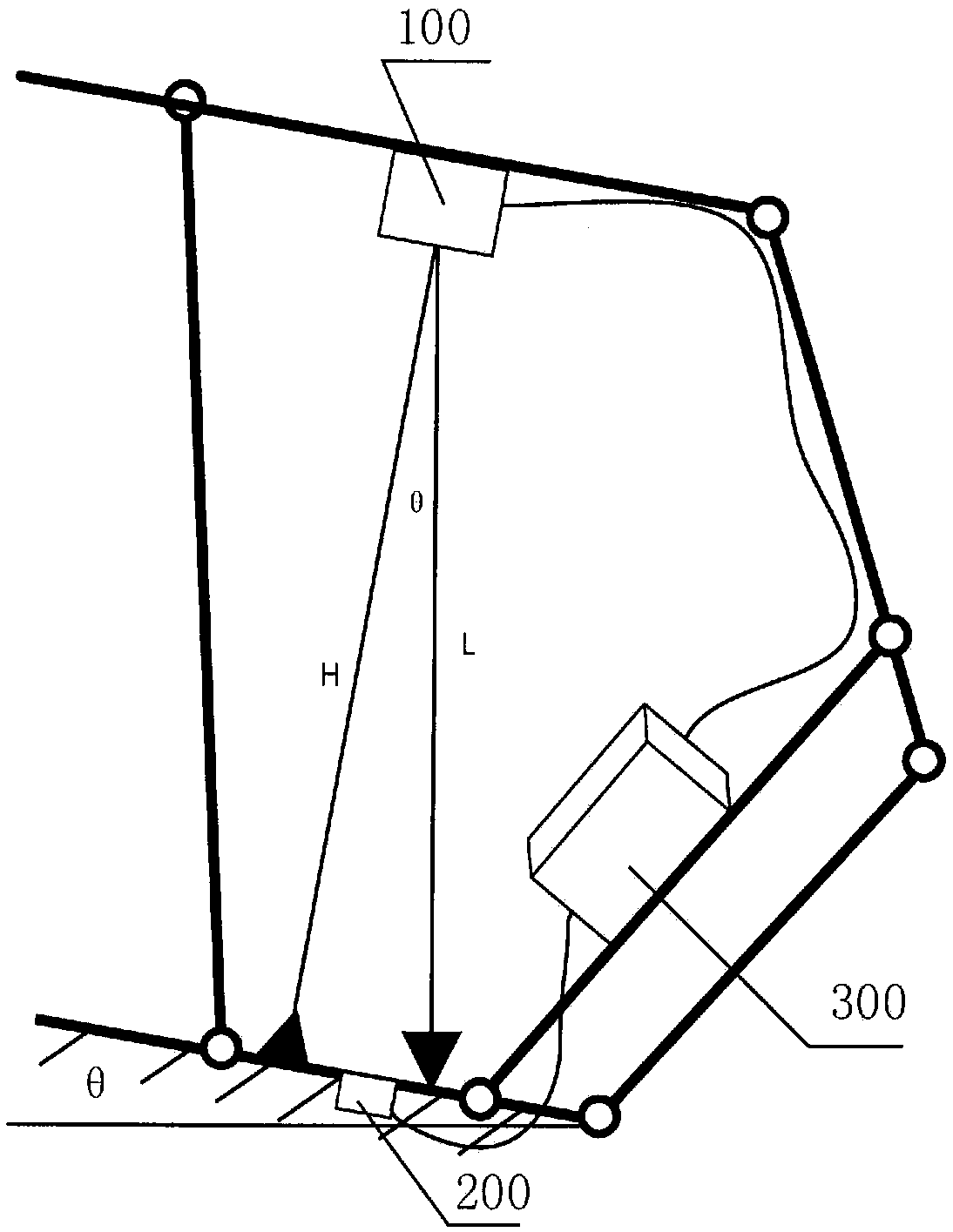

[0049] attached figure 2 A hydraulic support height measurement system and a method for measuring the actual height of the hydraulic support are shown. The problem to be solved is: when the fully mechanized mining face must adopt the down mining and upward mining processes due to the undulation of the coal seam, the support angle often deviates larger, as attached image 3 As shown, at present, except for the laser ranging method, other methods measure the distance between the hydraulic support and the plumb surface, that is, the plumb height L, or some height measurement methods measure the height between the plumb height L and the distance from the hydraulic pressure. There is a deviation between the actual height H of the support base and the vertical distance between the hydraulic support and the base, and when estimating the amount of coal mining or other calculations based on the height of coal mining, the parameter used should be the distance between the hydraulic top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com