Tokamak divertor target plate temperature accurate measurement method

A tokamak, accurate measurement technology, applied in the field of infrared temperature measurement, can solve the problem of principle error, not a fixed value, change, etc., to achieve the effect of improving accuracy, avoiding interference, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

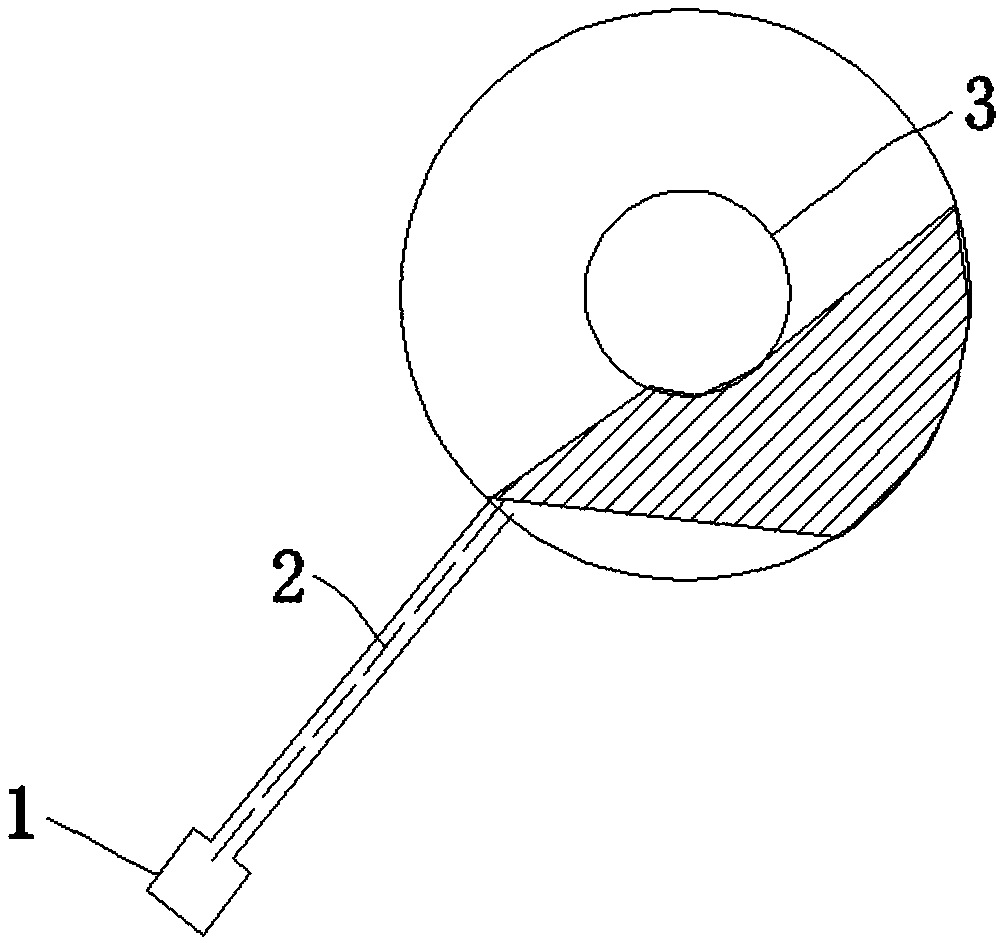

[0062] (1): According to figure 1 The way to connect the light path diagram and thermal imager. One end of the optical path extends to the interior of the tokamak through the window of the tokamak, and the other end of the optical path is connected to the infrared thermal imaging camera (the thermal imaging camera is connected to the PC through a data cable, and all operations on the thermal imaging camera are completed on the PC).

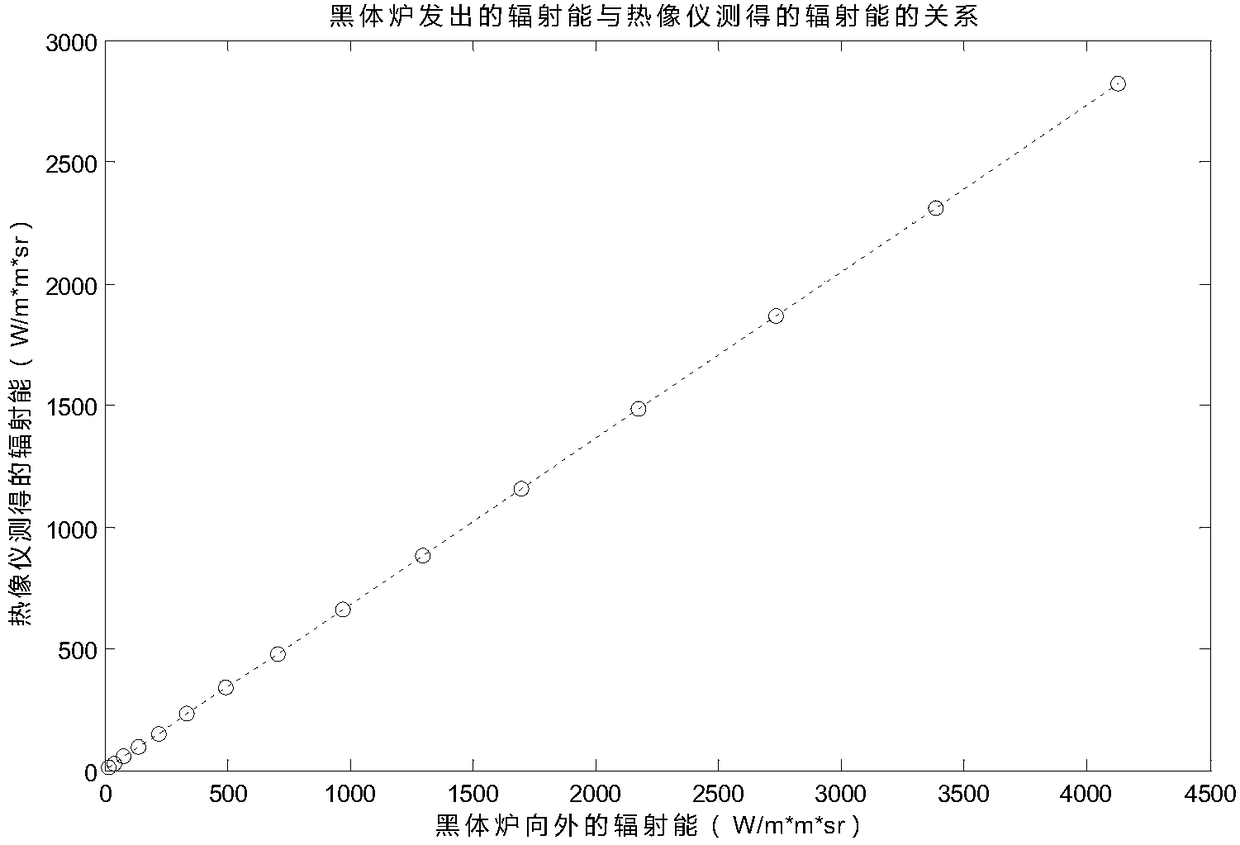

[0063] (2): Place the blackbody furnace inside the tokamak, align the window of the blackbody furnace with the optical path, start the thermal imager, adjust the focal length of the thermal imager to make the observation interface clear, and find the blackbody in the observation interface of the thermal imager Furnace windows, place detection points.

[0064] (3): Adjust the temperature of the blackbody furnace to 50 degrees Celsius. When the temperature of the blackbody furnace is stable to 50 degrees, take a photo and record the radiant energy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com