Gas channeling simulation system

A technology for simulating systems and gas channeling, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of test result deviation, complex device structure, cumbersome test operation, etc., and achieve the effect of ensuring normal operation and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] like figure 1 As shown, Embodiment 1 of the present invention provides a gas channeling simulation system, which may include a cement slurry unit, an air supply unit, a heating unit, and a test unit; wherein, the cement slurry unit communicates with the test unit, and the cement slurry unit is used to provide The cement used for testing; the air supply unit communicates with the test unit, and the air supply unit is used to provide a preset pressure for testing; the test unit is set in the heating unit, and the heating unit is used to provide a preset temperature for testing.

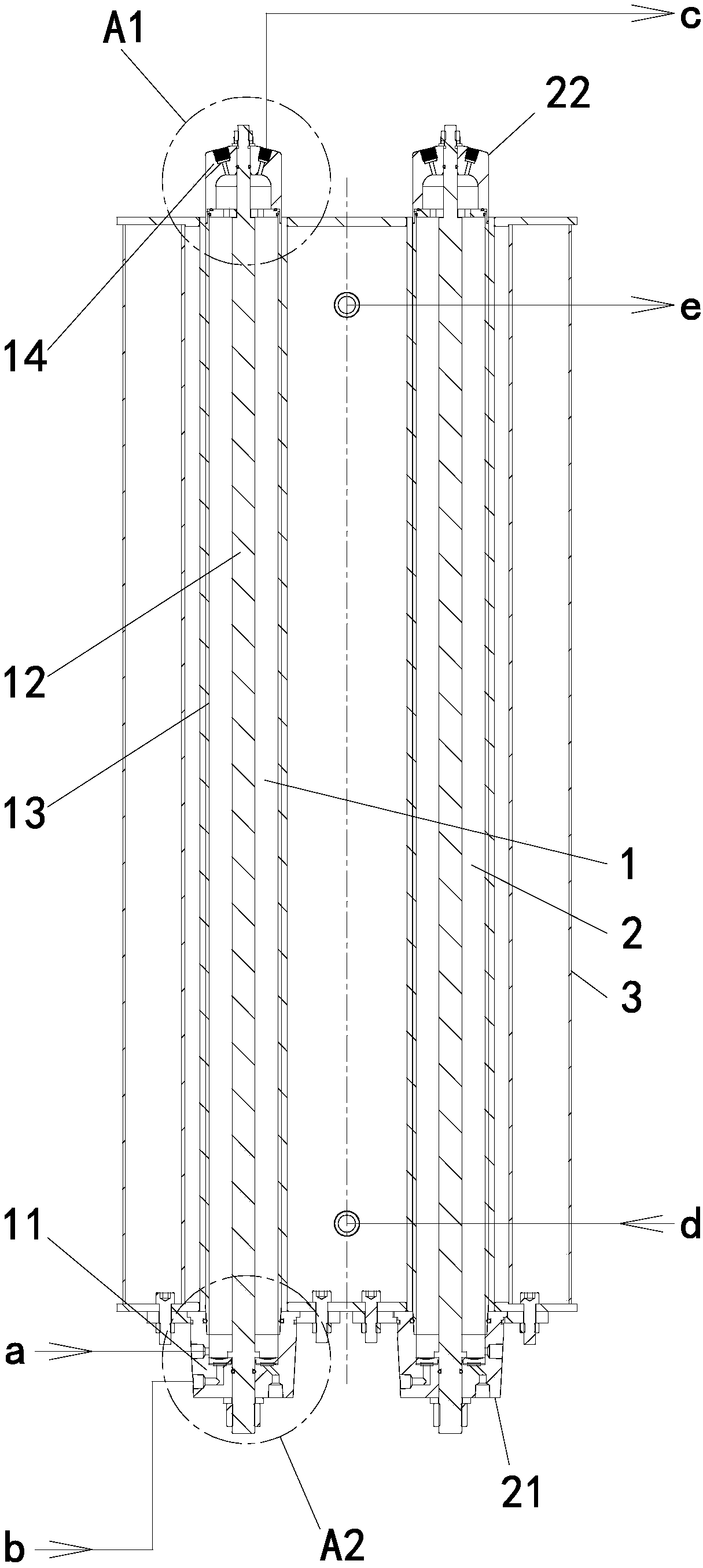

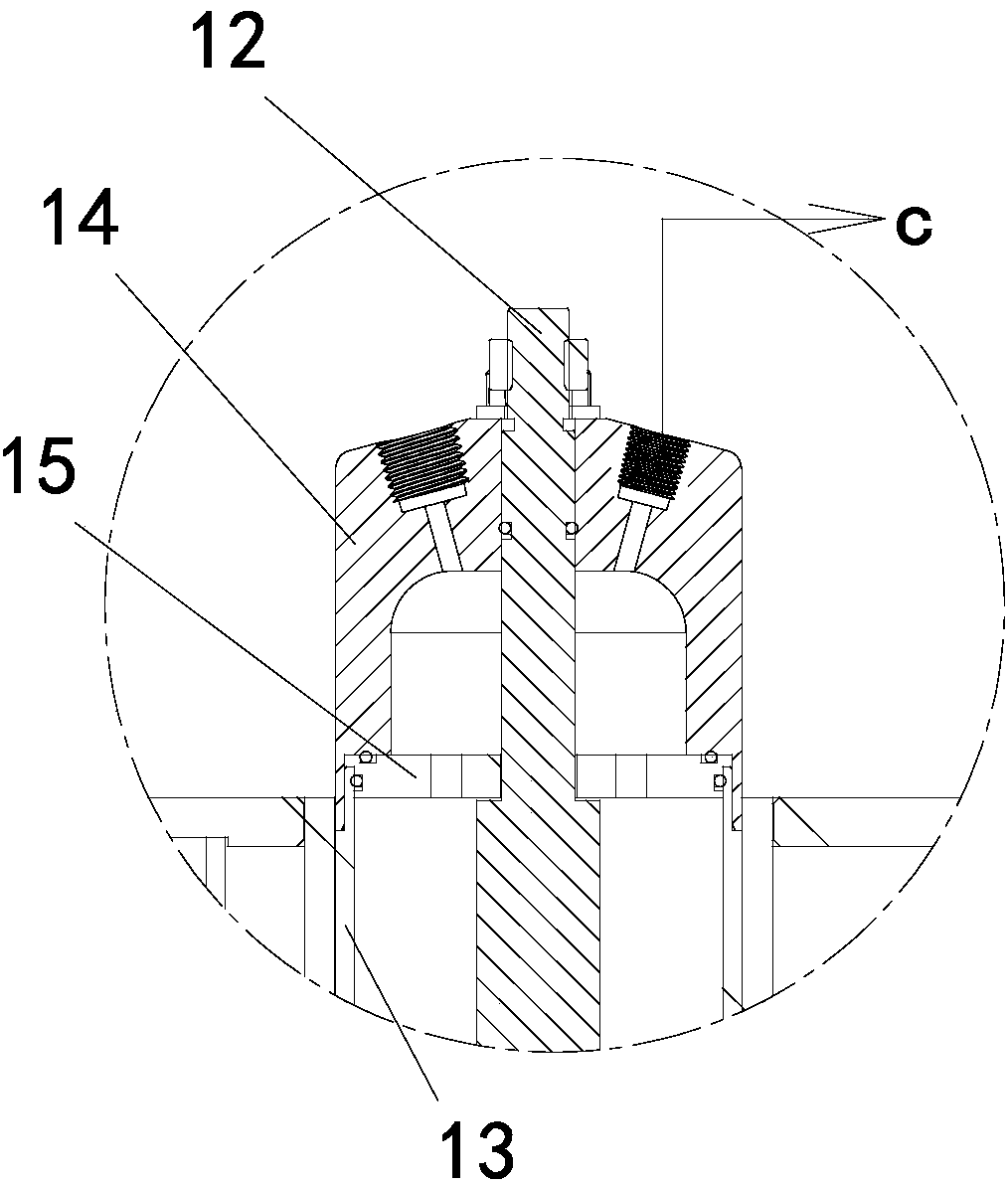

[0049] combine figure 2 , image 3 as well as Figure 4As shown, the test unit includes a heating cylinder 3, a gas channeling tube 1 for measuring the gas channeling process of cement, and a weight loss tube 2 for measuring the hydrostatic column pressure of cement; Inside the barrel 3, the gas channeling tube 1 and the weightlessness tube 2 are both provided with an annular cavity for conta...

Embodiment 2

[0078] Embodiment 2 of the present invention provides a simulation test method applied to the air channeling simulation system described in Embodiment 1, including:

[0079] Step a: Detect the hydrostatic column pressure value of cement per unit height in the weightless tube through the pressure detection mechanism, and calculate the hydrostatic column pressure value to be applied according to the detected value;

[0080] Step b: Perform pressurization operation through the pressure detection port of the gas channeling tube, apply the pressure value calculated above, measure the pressure at the bottom of the gas channeling tube and record the measured value;

[0081] Step c: When the pressure detection mechanism detects that the measured value of the gas channeling tube reaches a predetermined value, the gas with a constant pressure is introduced from the first gas input port;

[0082] Step d: Detect the amount of cement air channeling in the annular cavity through the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com