Novel rice seed processing method and production line of rice seeds

A technology of rice seeds and processing methods, applied in chemical instruments and methods, solid separation, separating solids from solids with air flow, etc., can solve problems such as low efficiency, achieve improved production capacity, reasonable design, and solve production efficiency low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1. This example provides a new type of rice seed processing method

[0021] The purpose of this embodiment is to solve the technical problem of low rice seed production effect caused by the limited capacity of the specific gravity separator in the existing rice seed processing production line. For this reason, this embodiment mainly reduces the workload of the specific gravity separator and reduces The work load of the specific gravity sorting machine is used to improve the efficiency of the entire production line. In order to achieve the above-mentioned purpose, the new rice seed processing method provided in this embodiment mainly includes the following effective steps:

[0022] First, use the air screening equipment to screen out most of the heavy, large, light or diseased seeds from the rice seeds. In this way, the other impurities in the rice seeds are reduced on a large scale. Then, the air-screened rice The seeds are sorted by a vibration separator. After the ...

Embodiment 2

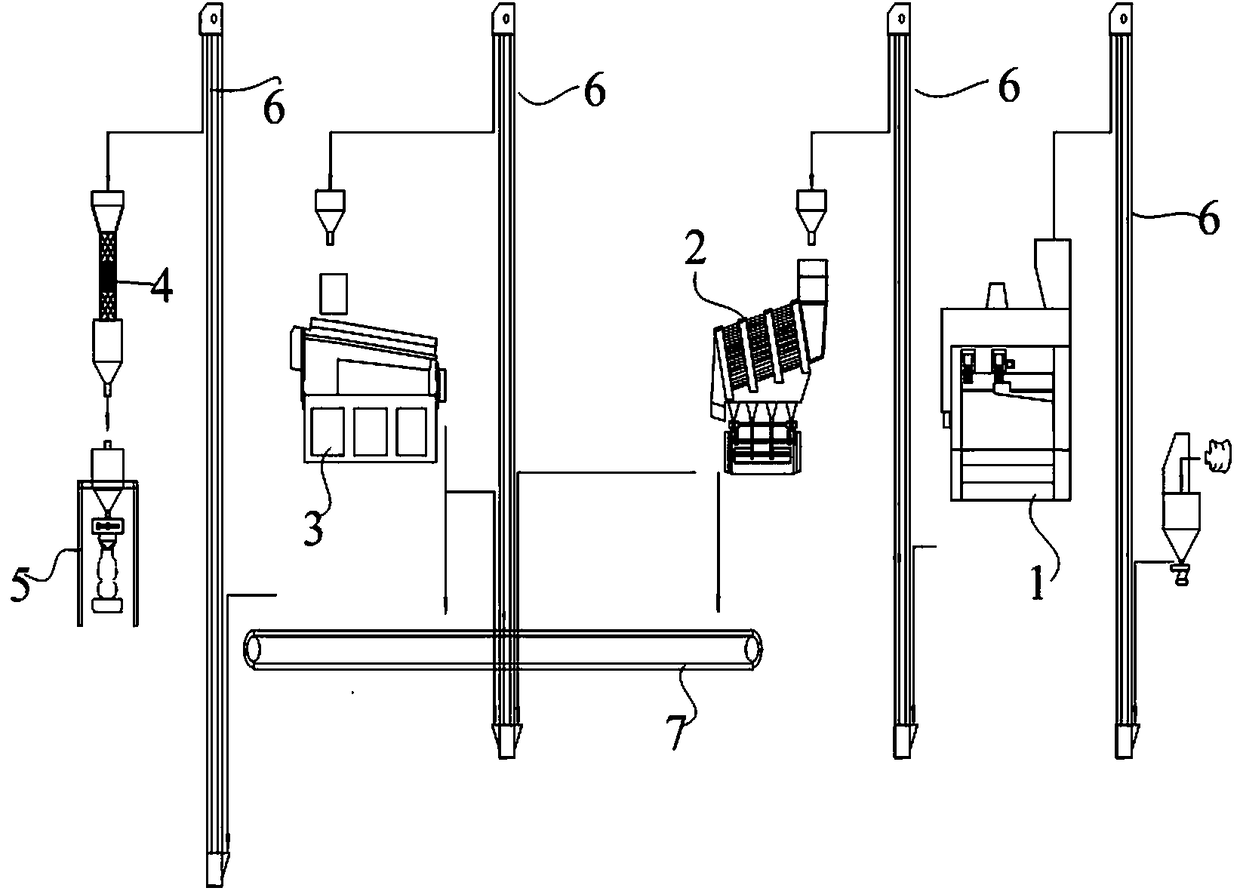

[0025] Embodiment 2. This embodiment provides a new type of rice seed processing production line

[0026] Such as figure 1 As shown, this embodiment is a production line designed mainly based on the method provided in Embodiment 1. For this reason, the new rice seed processing production line provided in this embodiment includes a wind screen 1 and a vibrating machine arranged in sequence along the material movement direction. The sorting machine 2, the specific gravity sorting machine 3, the static mixer 4 and the packaging machine, wherein the packaging machine 5 is a measuring packaging machine. A bucket elevator 6 is installed before the wind screen 1, the vibrating separator, the specific gravity separator 3, and the static mixer 4, and a conveyor belt 7 is also provided between the vibration separator 2 and the specific gravity separator 3. , Conveyor belt 7 mainly has 2 purposes. 1 is to transport the remaining material separated by the vibrating separator 2 to the specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com