Method for solving cracks on surfaces of Inconel alloy castings

A surface crack and alloy casting technology, applied in the field of casting manufacturing, can solve the problems of casting surface cracks, high production cost, and difficult repair, etc., and achieve the effect of solving casting surface cracks, low production cost, and product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

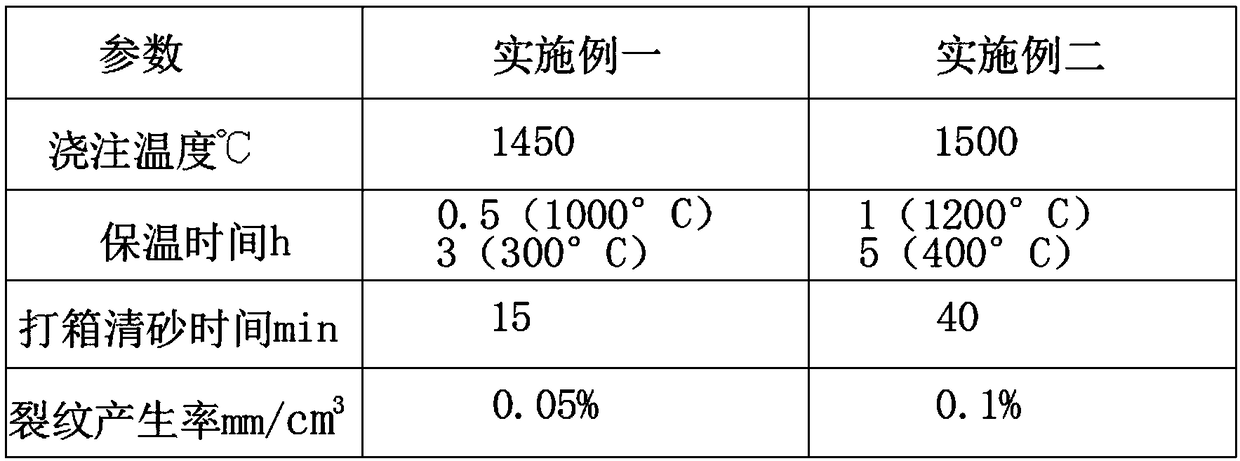

[0024] The technical scheme that present embodiment adopts is: its operating steps are as follows:

[0025] 1. Pouring is carried out according to the conventional requirements, and the pouring temperature is determined to be 1500°C according to factors such as the wall thickness of the casting;

[0026] 2. Determine the holding time through MAGMA simulation software and on-site temperature measurement to ensure that the molten steel in the mold is completely solidified;

[0027] 3. According to the determined heat preservation time, the sand is removed from the box, and the entire sand removal process is completed within 40 minutes according to the different requirements of the casting size and wall thickness;

[0028] 4. Reserve a well-ventilated space in advance for placing castings;

[0029] 5. Place the cleaned castings in an open space to cool naturally.

[0030] Further, the holding time in step 2 is 6 hours, 1 hour when the holding temperature is 1200°C, and 5 hours ...

Embodiment 1

[0031] The dimensions of the castings in Embodiment 1 and Embodiment 2 are the same, and the material is CW6MC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com