Wallboard processing system and processing method thereof

A processing system and processing method technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve problems such as warping of boards, poor flatness, wall deformation, etc., to ensure processing quality, space interval, etc. Large and thick for the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

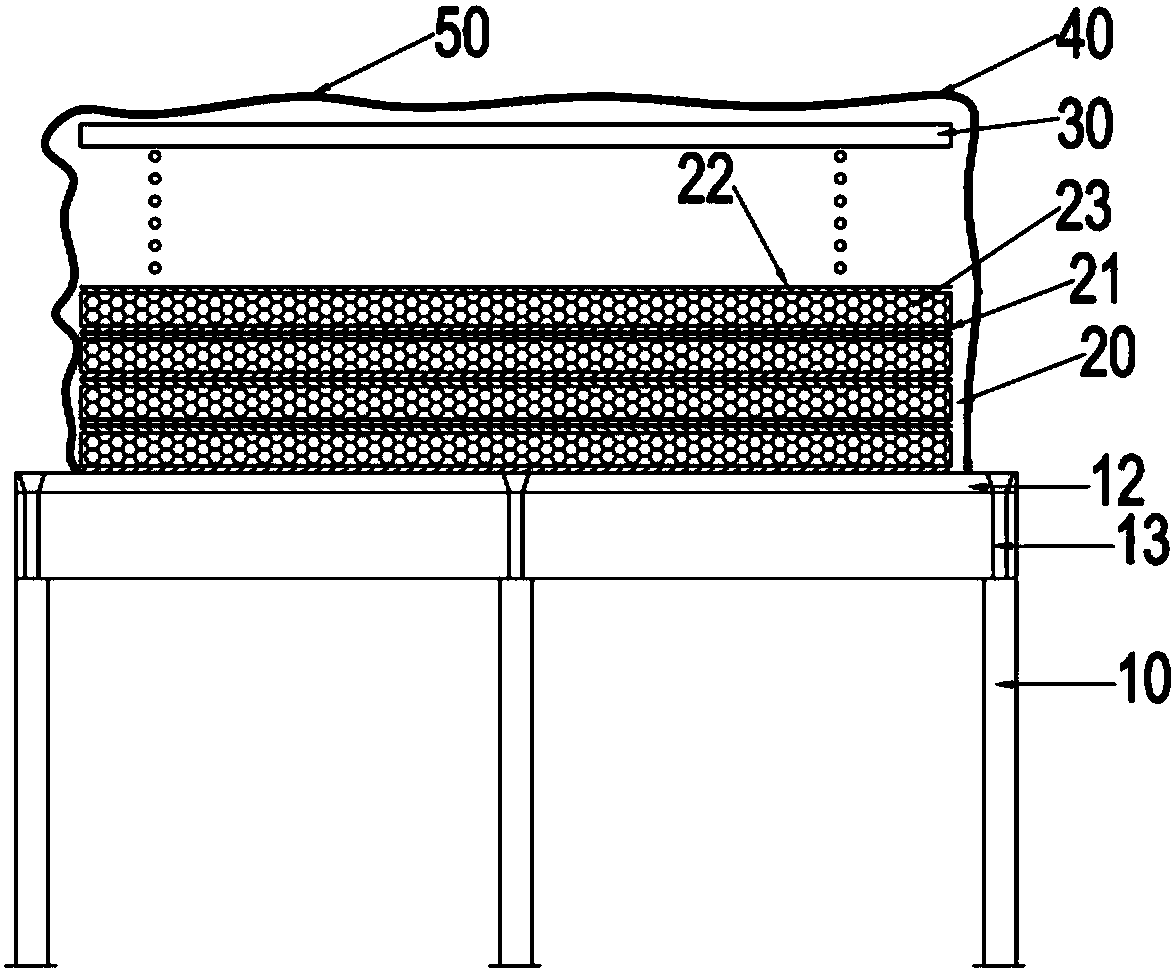

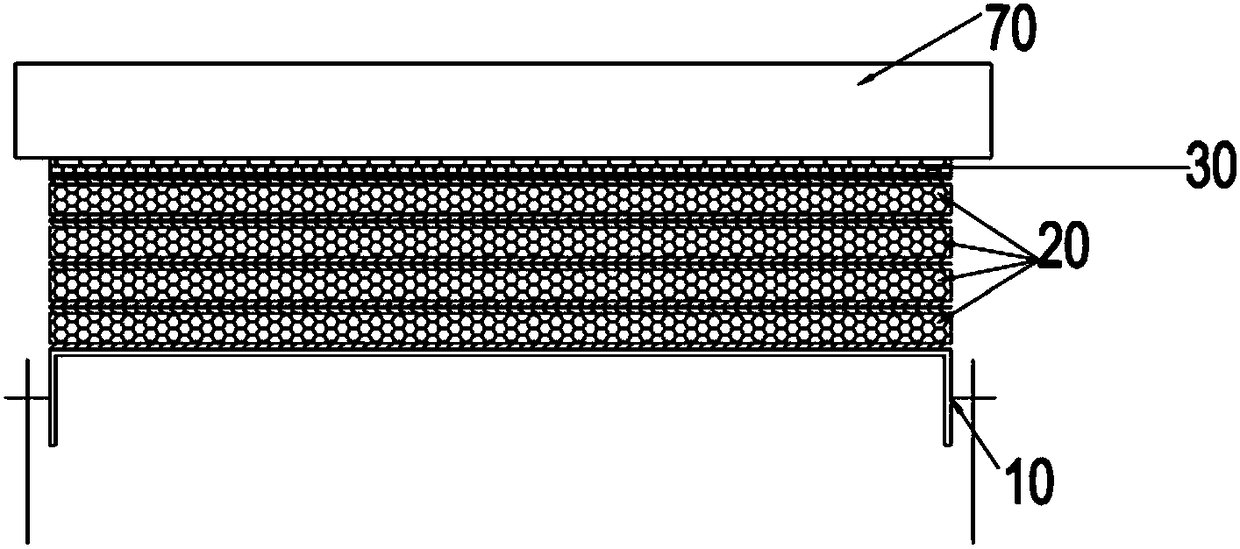

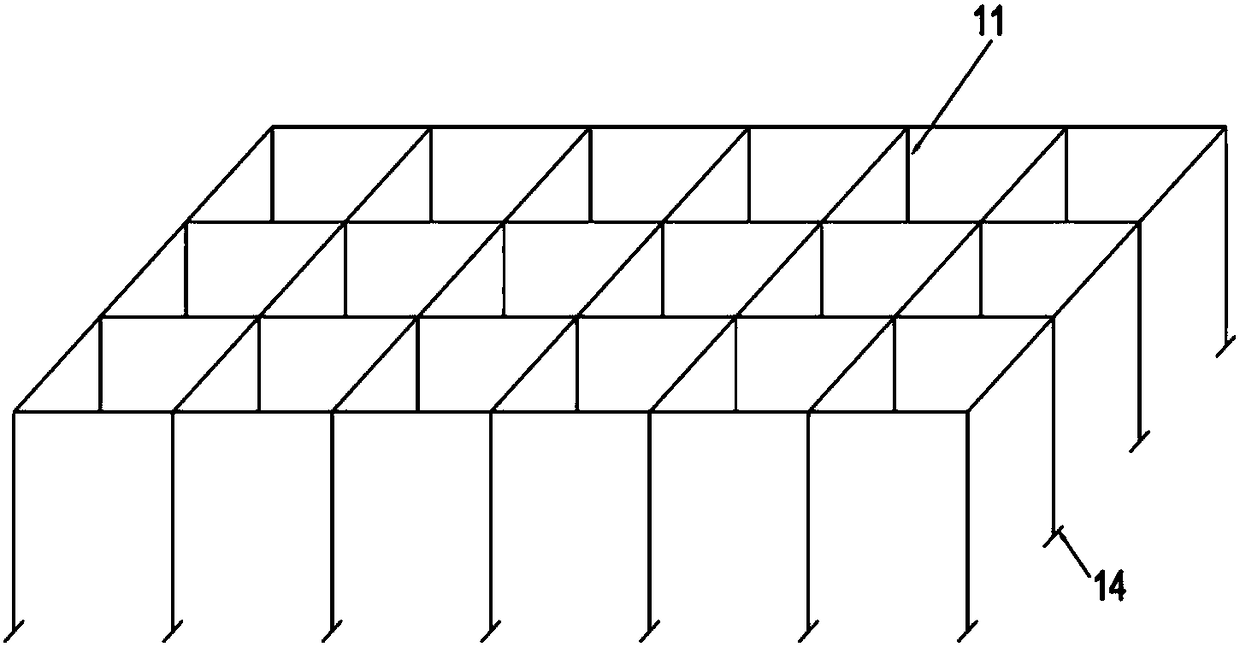

[0039] Such as figure 1 and figure 2 As shown, the wallboard processing system of this embodiment, the processing system includes a reference platform 10, a multi-layer wallboard 20, a first molded plate 30, a fiber blanket 40, a plastic film 50 and a negative pressure device, the reference platform 10 A through-hole structure communicating with the negative pressure device is provided on both sides, the multi-layer wall panels 20 are stacked layer by layer on the reference platform 10, and the first molded board 30 is placed on the highest wall On the board 20, the fiber blanket 40 is wrapped and arranged on the outer periphery of the first molded board 30 and the wall panel 20, the plastic film 50 is wrapped and arranged on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com