Rock mechanics test numerical simulation method based on ABAQUS

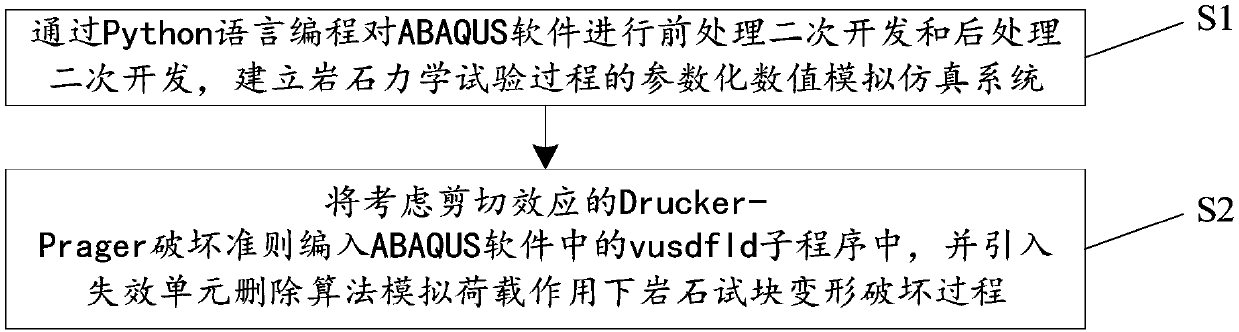

A technology of rock mechanics and numerical simulation, applied in the field of rock mechanics tests, to enrich the content of mechanical tests and improve the efficiency of modeling and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

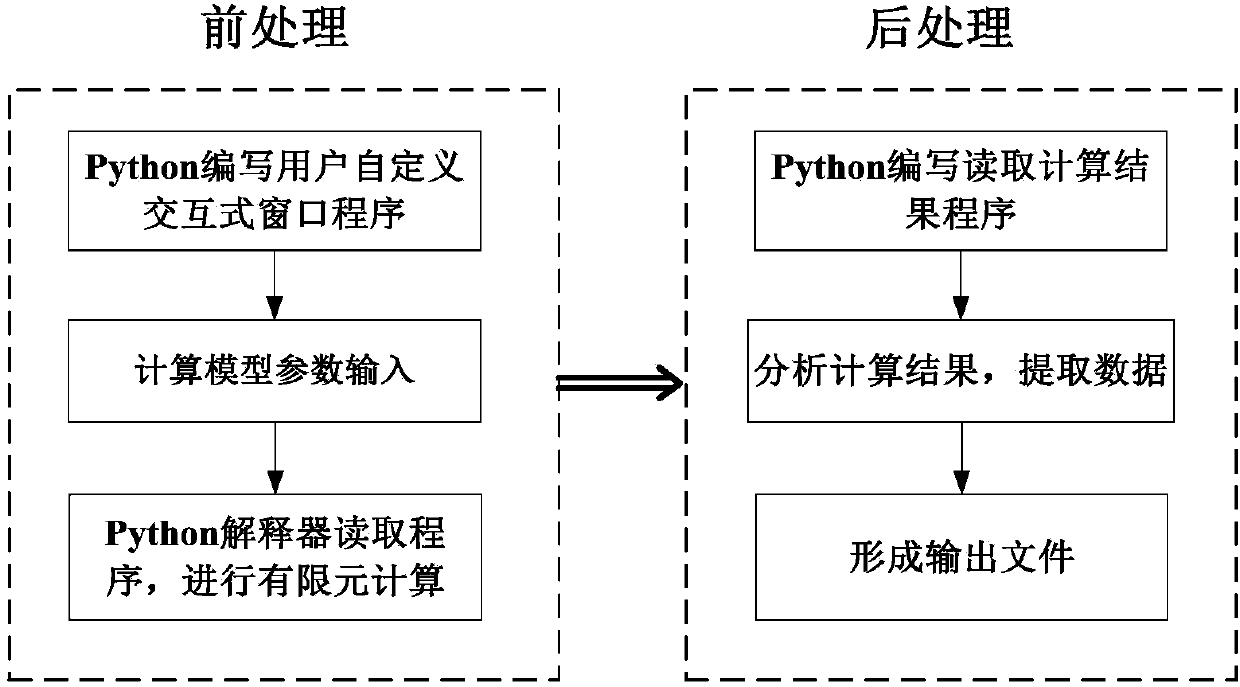

Method used

Image

Examples

Embodiment 1

[0053] Granite is hard, compact and high-strength, and is a relatively common engineering rock mass. The rock core obtained from a project site was selected and processed into 2 standard samples of φ50mm×100mm, and the triaxial compression test was carried out on the RMT multifunctional rock testing machine (confining pressure 10MPa). The sample deviatoric stress-axial strain relationship curve is obtained from the triaxial compression test, such as Figure 5 shown. The failure of the granite sample as Figure 6 shown. It can be seen that the failure mode of granite samples under triaxial compression is relatively consistent, which belongs to shear failure, so it is reasonable to use the D-P criterion considering the shear effect as the criterion for rock failure.

[0054] The experimental data of the loading process of the two test blocks were sorted out, and the physical and mechanical parameters of each sample were obtained as shown in Table 2. At the same time, accordi...

Embodiment 2

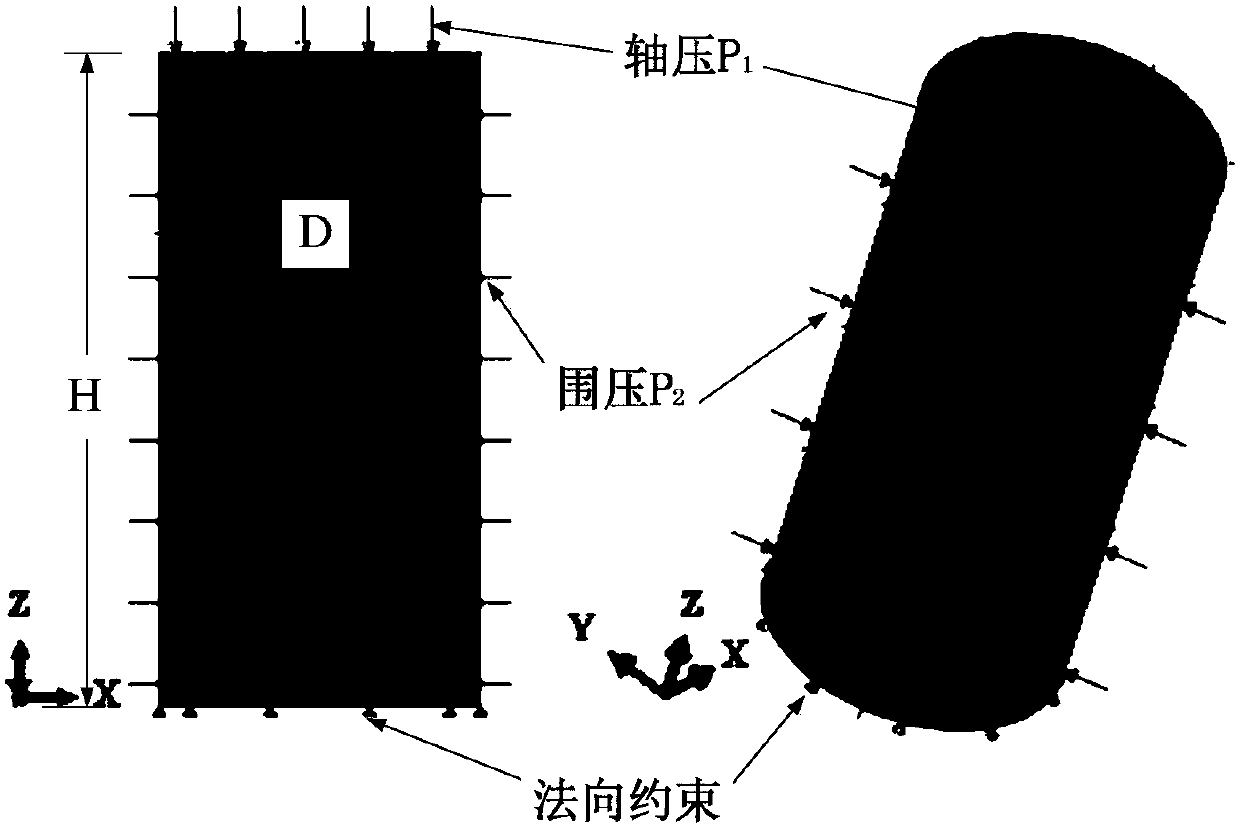

[0058] Call the numerical simulation system of rock mechanics test, use Figure 4a , Figure 4b and Figure 4c The user-defined interactive window shown in the figure enters the corresponding coefficients to simulate the failure process of the granite sample. User-defined interactive window parameters are entered as follows:

[0059] Loading parameter setting: the axial pressure P1 is set to 250000000Pa, and the surrounding rock is set to 10000000Pa.

[0060] Sample geometric parameter setting: the sample height H is set to 100mm, and the diameter D is 50mm.

[0061] The setting of mechanical parameters of the test block: see Table 2, the cohesion force is set to 27000000Pa, and the friction angle is 45°.

[0062] The loading process of the test block is simulated by the numerical simulation system of the rock mechanics test, and the obtained simulation results are as follows: Figure 7 shown. It can be seen that after the loading of the test block, the whole is divided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cohesion | aaaaa | aaaaa |

| Friction angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com