Full-automatic code scanner

A code scanning machine, fully automatic technology, applied in the direction of conveyors, conveyor objects, computer parts, etc., can solve problems that affect production efficiency and do not conform to the development process of industrial modernization, and achieve the effect of improving code scanning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

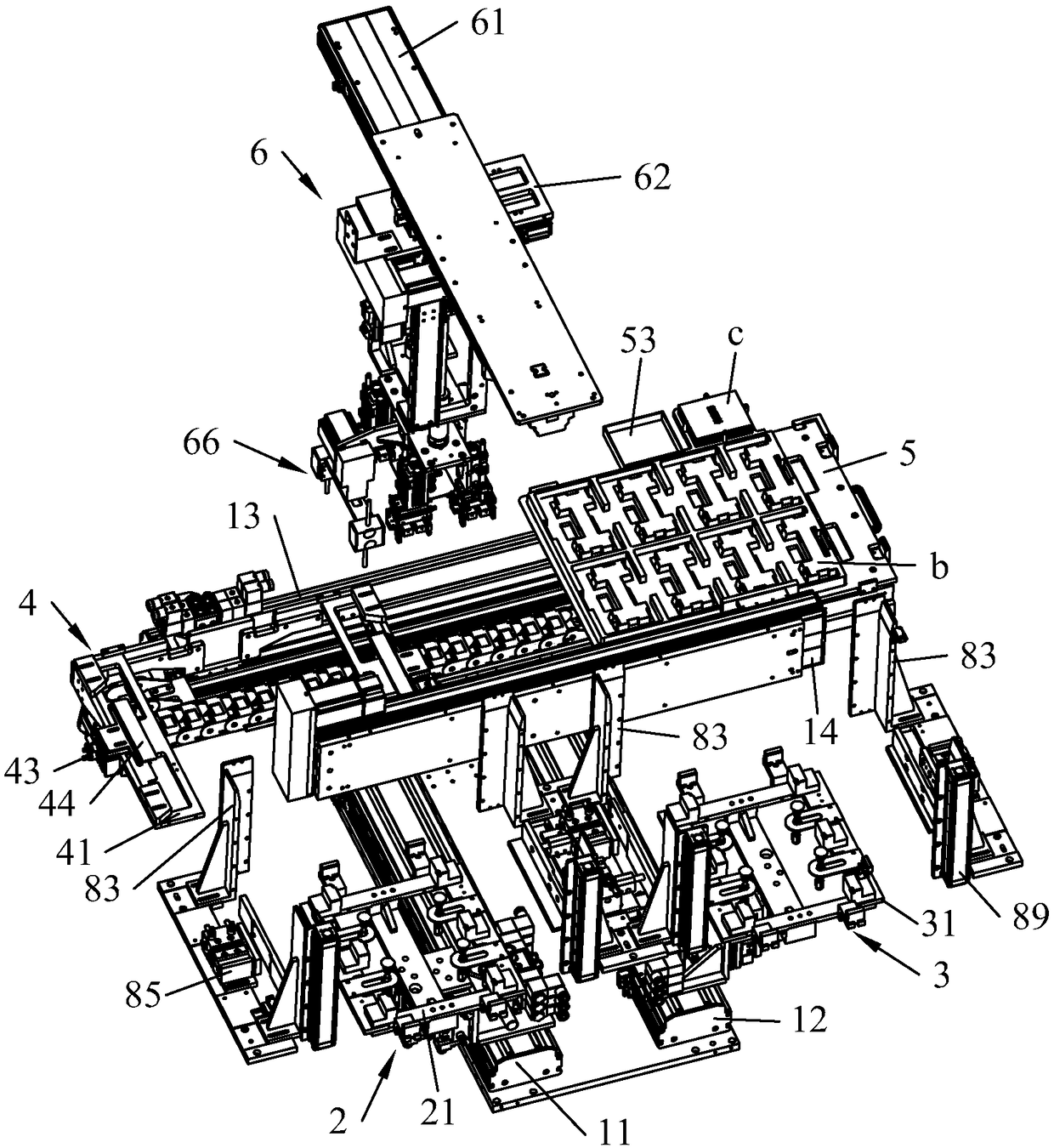

[0029] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

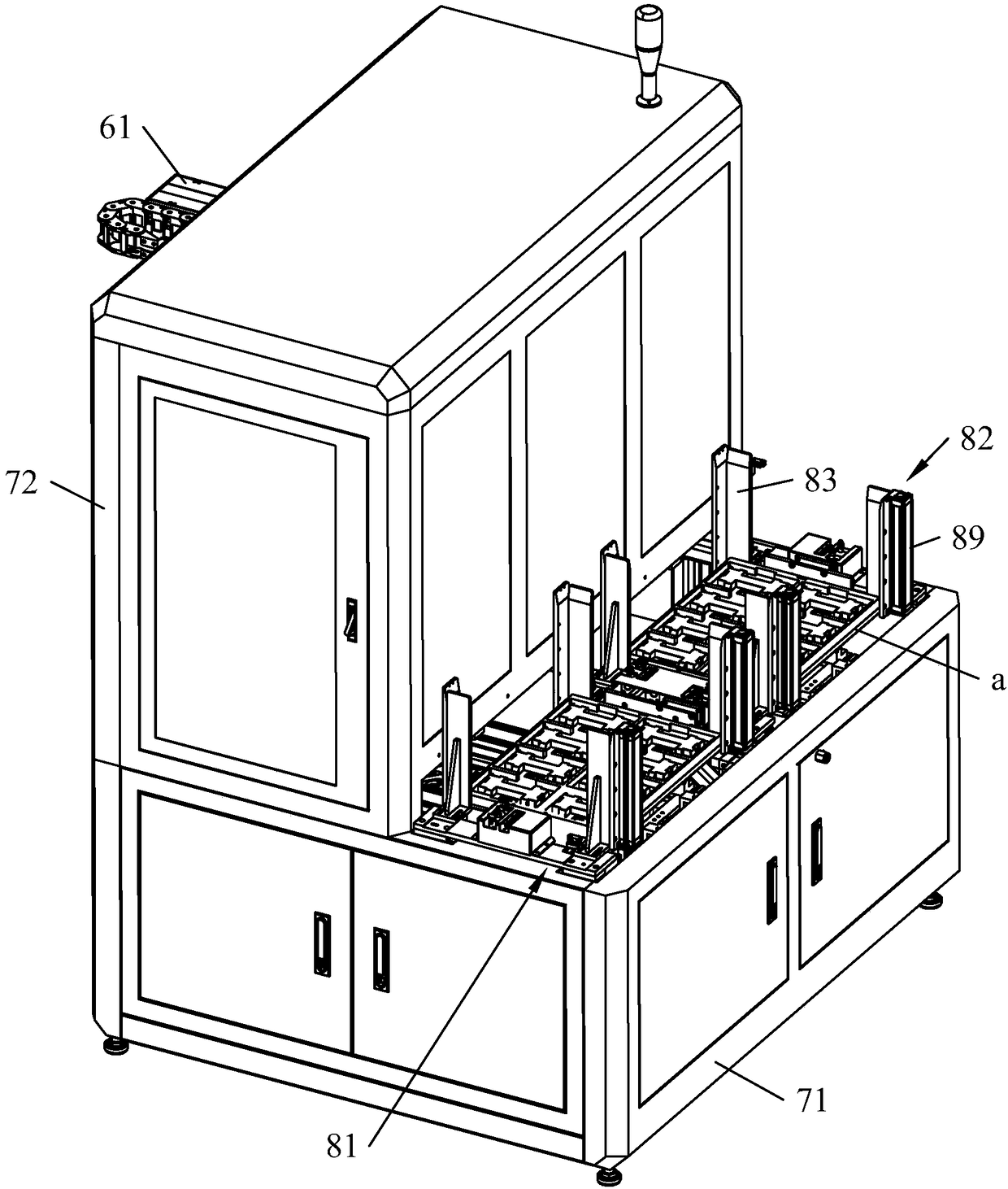

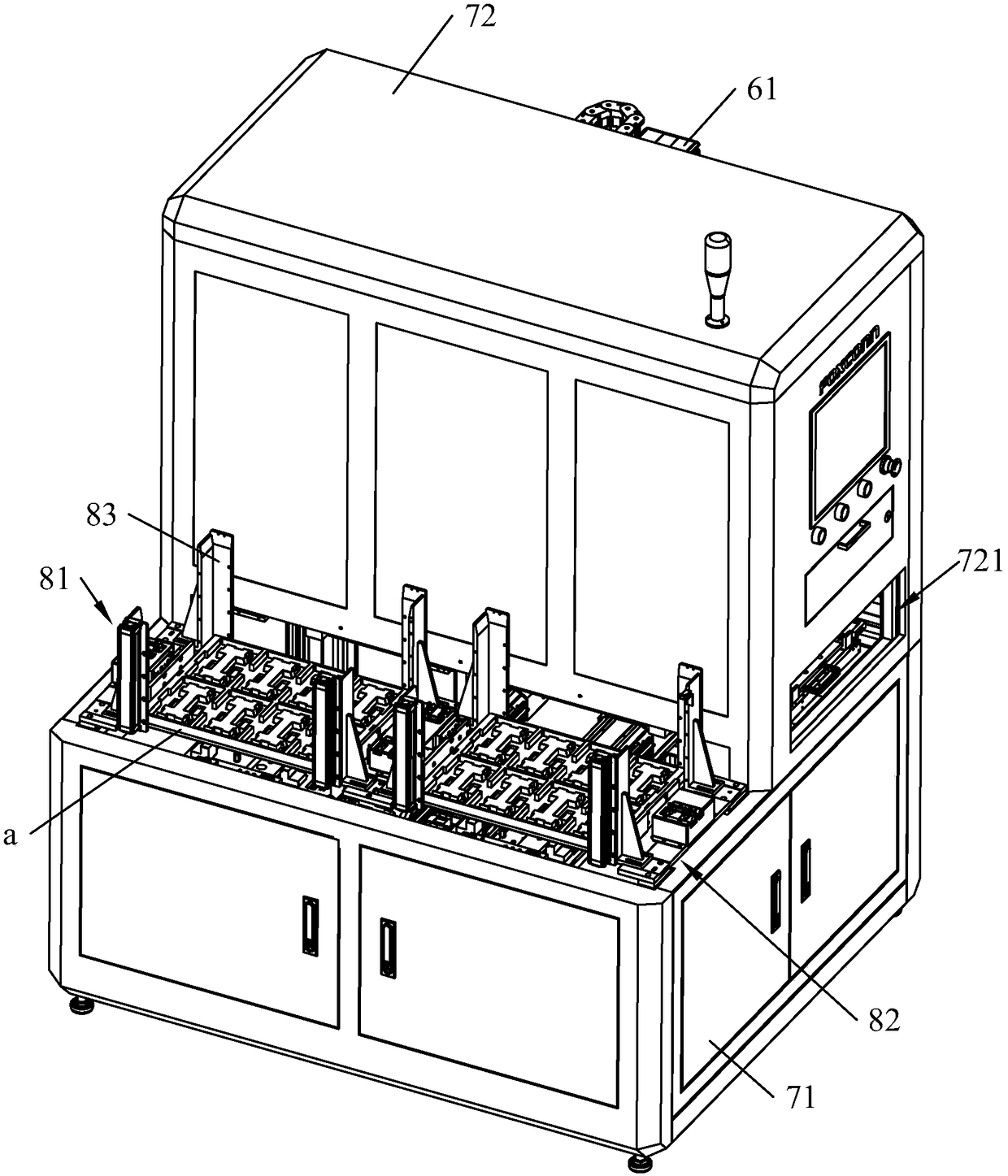

[0030] combine Figure 1 to Figure 3 As shown, the present invention provides a fully automatic code scanning machine, which can realize automatic code scanning of products and reject defective products during the code scanning process. When scanning the code, multiple products are loaded in a tray a, and the products are sent into the automatic code scanning machine with the tray a as the unit.

[0031] The automatic code scanning machine includes a frame and an input guide rail 11, an output guide rail 12, a first support mechanism 2, a second support mechanism 3, a traverse guide rail 13, and an intermediate support frame 4. Temporary storage rack 5 and code scanning and retrieving mechanism 6. The frame includes a lower frame 71 and an upper frame 72 fixed on the top of the lower frame 71. The upper frame 72 is biased to one side of the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com