Full-automatic mattress spring frame manufacturing method and device

A production method and fully automatic technology, applied in the field of mattress spring frames, can solve the problems of high labor intensity, large floor space, and scattered distribution of equipment, and achieve high production efficiency, small floor space, and high degree of intensification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

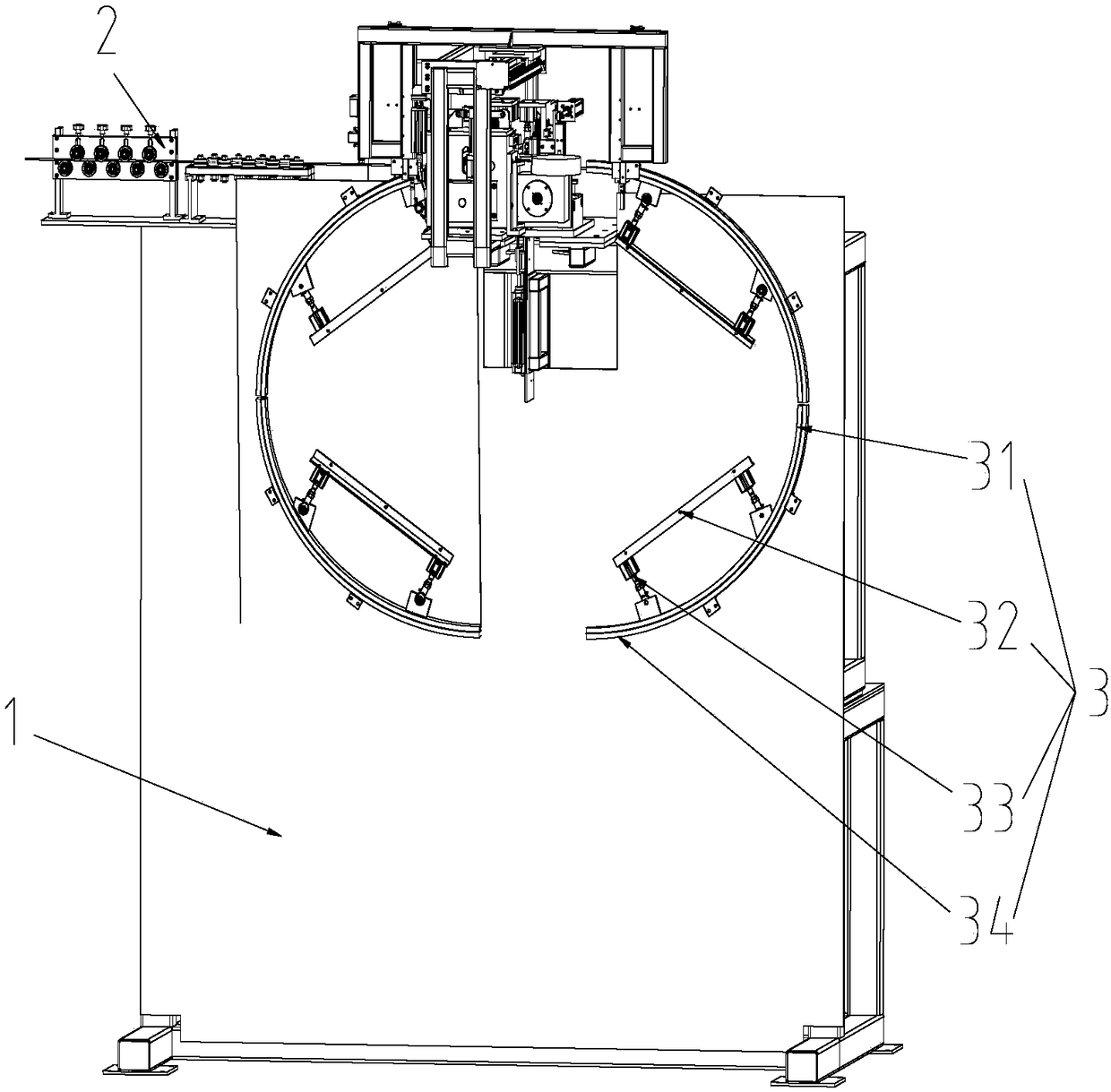

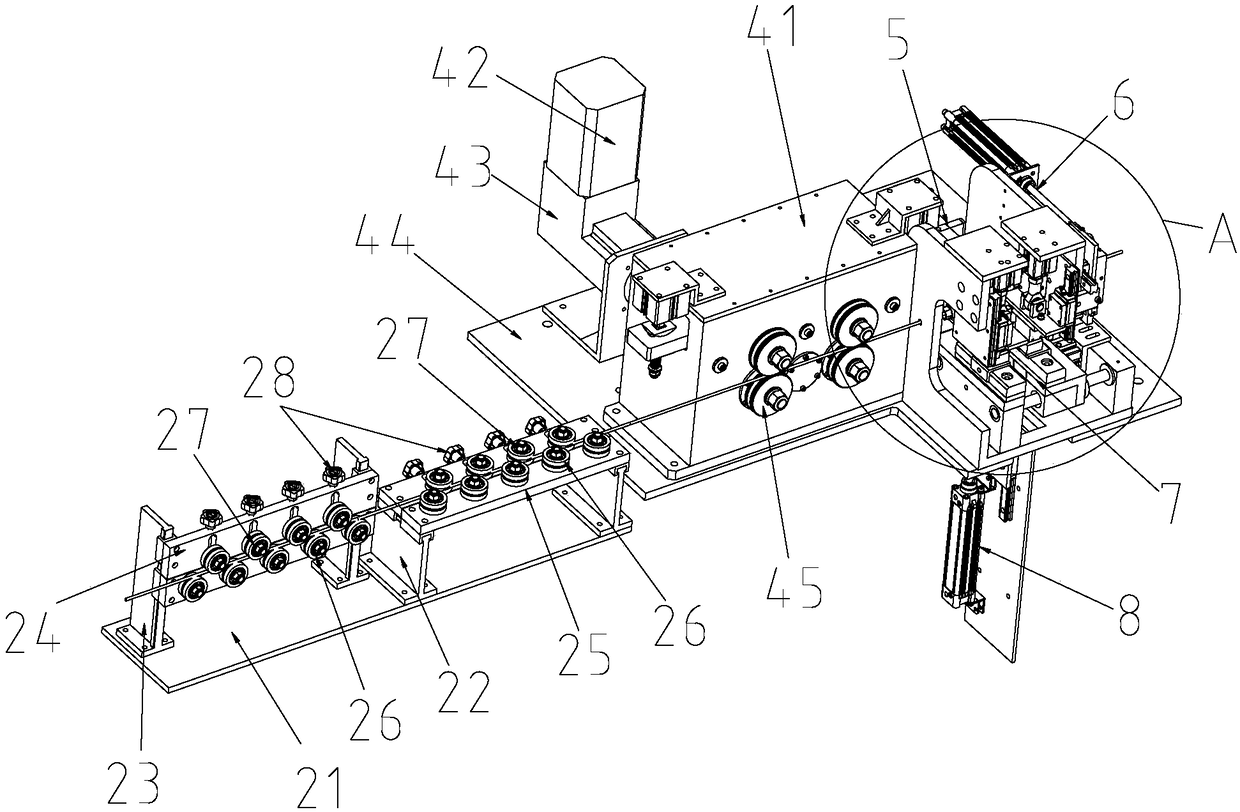

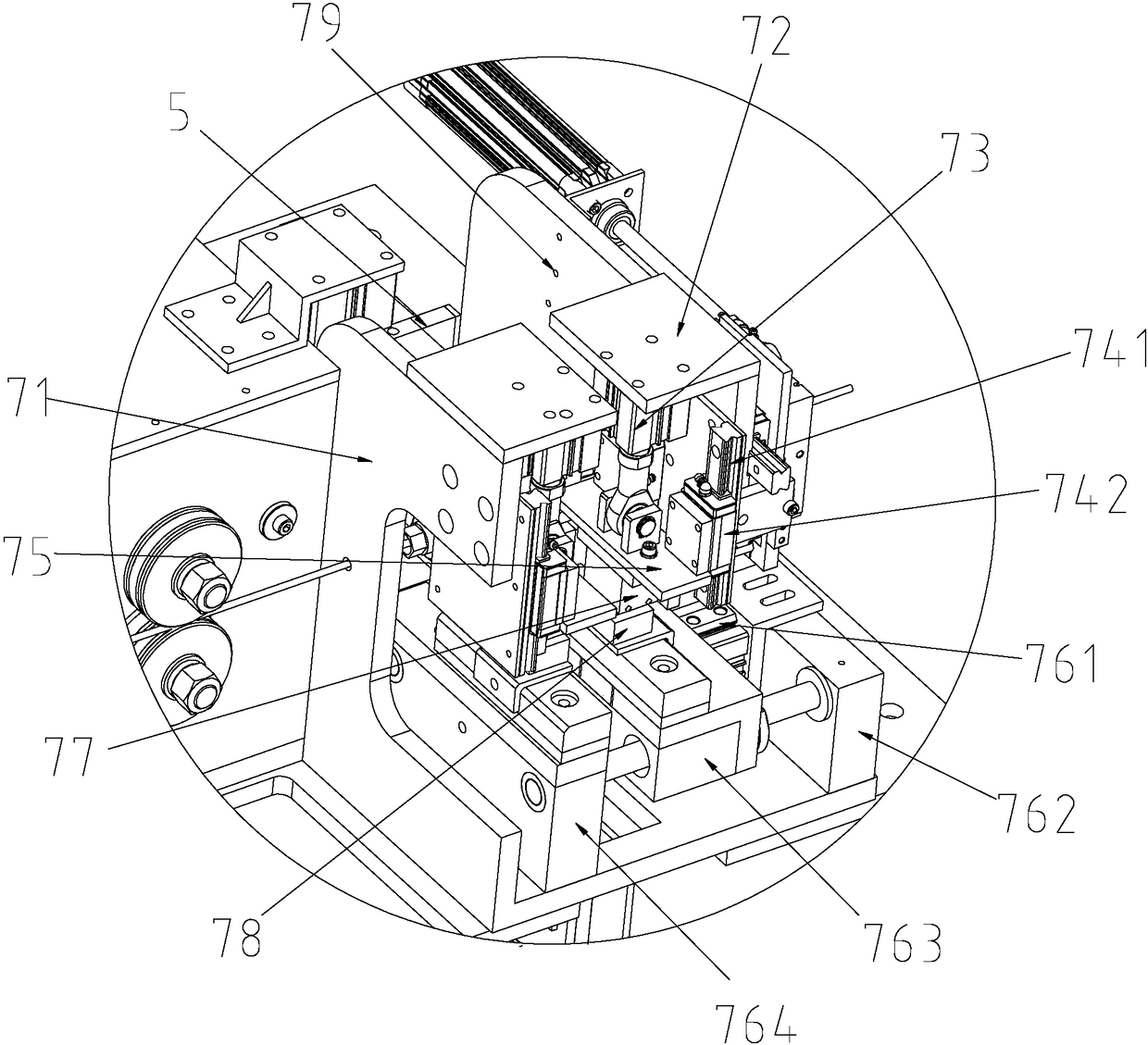

[0032] See attached Figure 1 to Figure 10 As shown, a fully automatic mattress spring frame manufacturing equipment in this embodiment adopts the following bending method:

[0033] Step 1. First straighten the steel wire and cut it to a fixed length according to actual needs;

[0034] Step 2. Butt the two ends of the cut steel wire to form a traveler. In this embodiment, the butt joint method is welding. Of course, other connection methods can also be used, such as clamping the two ends of the steel wire with connectors fixed;

[0035] Step 3. Perform fixed-length bending for the traveler, and fold the ring-shaped traveler into a spring frame with a rectangular structure.

[0036]The above-mentioned spring frame production equipment includes a base frame 1 for support, a straightening wire feeding device and a welding mechanism 7 are arranged on the base frame 1, a guide plate is arranged on the base frame 1, and a guide plate is arranged on the guide plate Steel wire guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com