Deburring mechanism

A technology of deburring mechanism and guide rails, applied in mechanical equipment, gear teeth, grinding machines, etc., can solve problems such as damage to workpieces, iron filings endangering the safety of workers, and deburring discs cannot be completely fitted, etc., to improve the grinding effect and stress Uniform and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

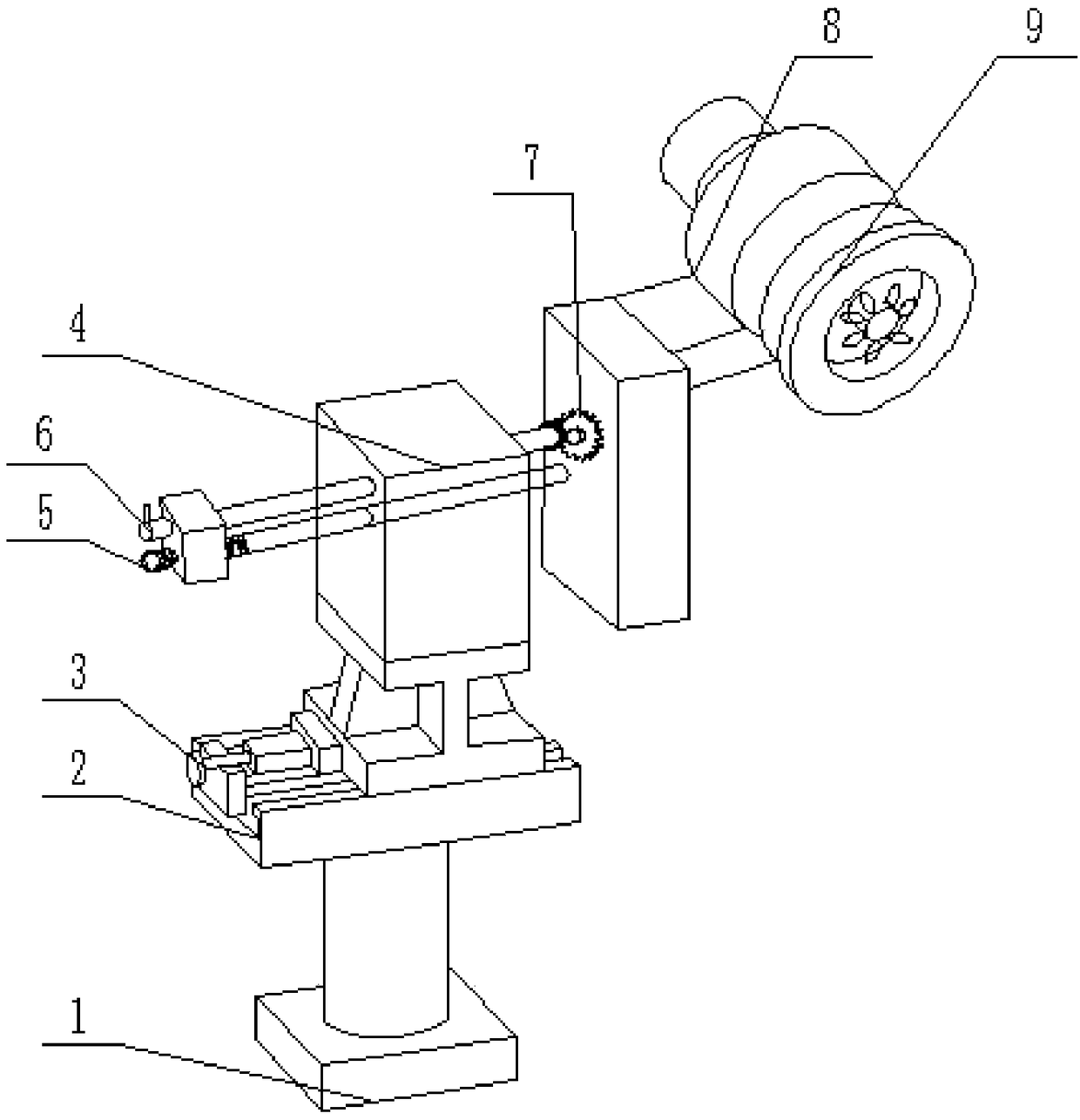

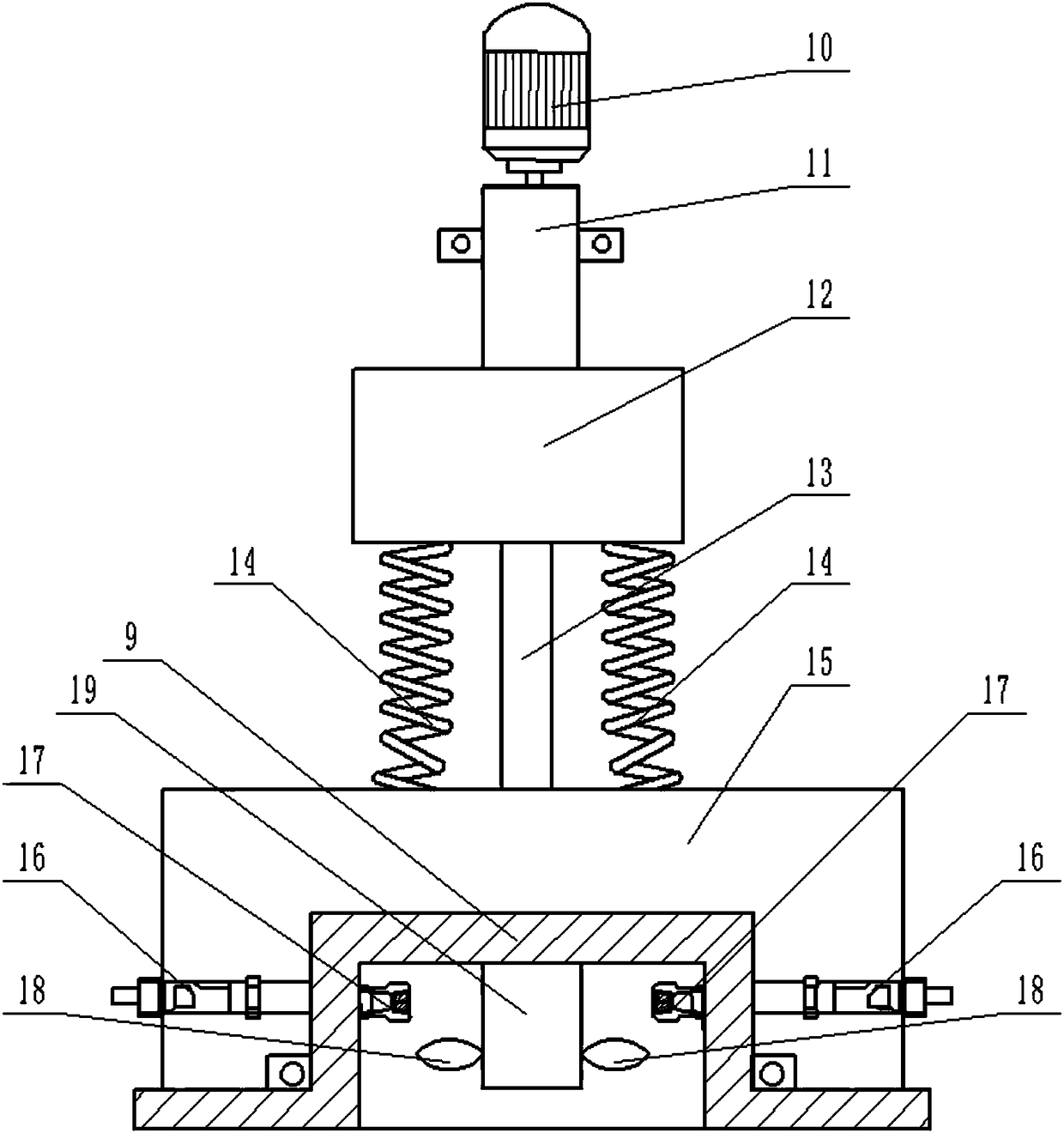

[0019] Instructions attached Figures 1 to 2 The reference signs in include: supporting column 1, adjusting guide rail 2, adjusting lead screw 3, guide rail seat 4, guide rail 5, worm screw 6, worm wheel 7, deburring disc seat 8, deburring disc 9, drive motor 10, input shaft 11. Disc 12, flexible shaft 13, spring 14, fixed seat 15, rotary joint 16, check valve 17, fan blade 18, drive shaft 19.

[0020] Such as figure 1 As shown, a deburring mechanism includes a support column 1, an adjustment guide rail 2 is installed on the upper end of the support column 1, an adjustment screw 3 is installed on the left end of the adjustment guide rail 2, a guide rail seat 4 is installed on the upper end of the adjustment guide rail 2, and the adjustment screw 3 and Described guide rail seat 4 forms leading screw nut mechanism, and the side wall of guide rail seat 4 is equipped with g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com