Plasticizing extruder for waste rubber and plastic molten recovery materials

A recycled material and extruder technology, which is applied in the field of rubber and plastic processing, can solve the problems of poor strength and toughness of recycled rubber and plastics, and achieve the effect of improving strength and toughness, good strength and toughness, and fast and reliable material distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

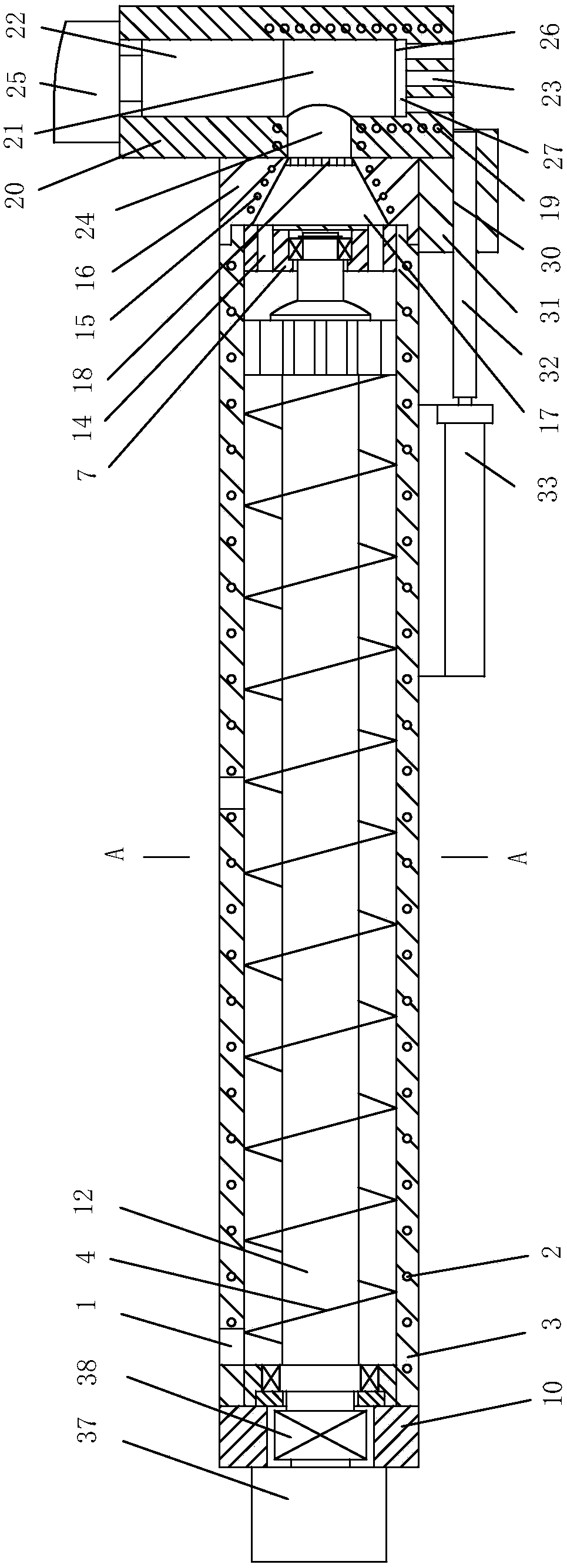

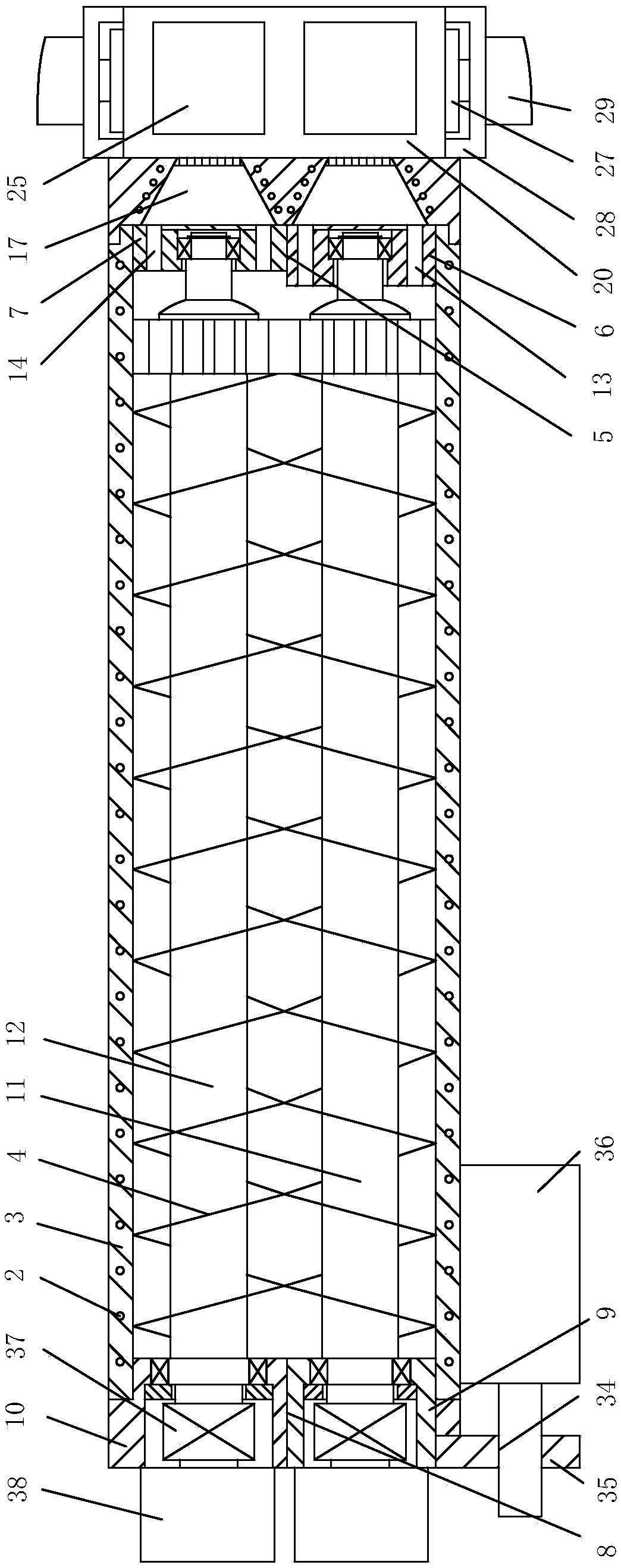

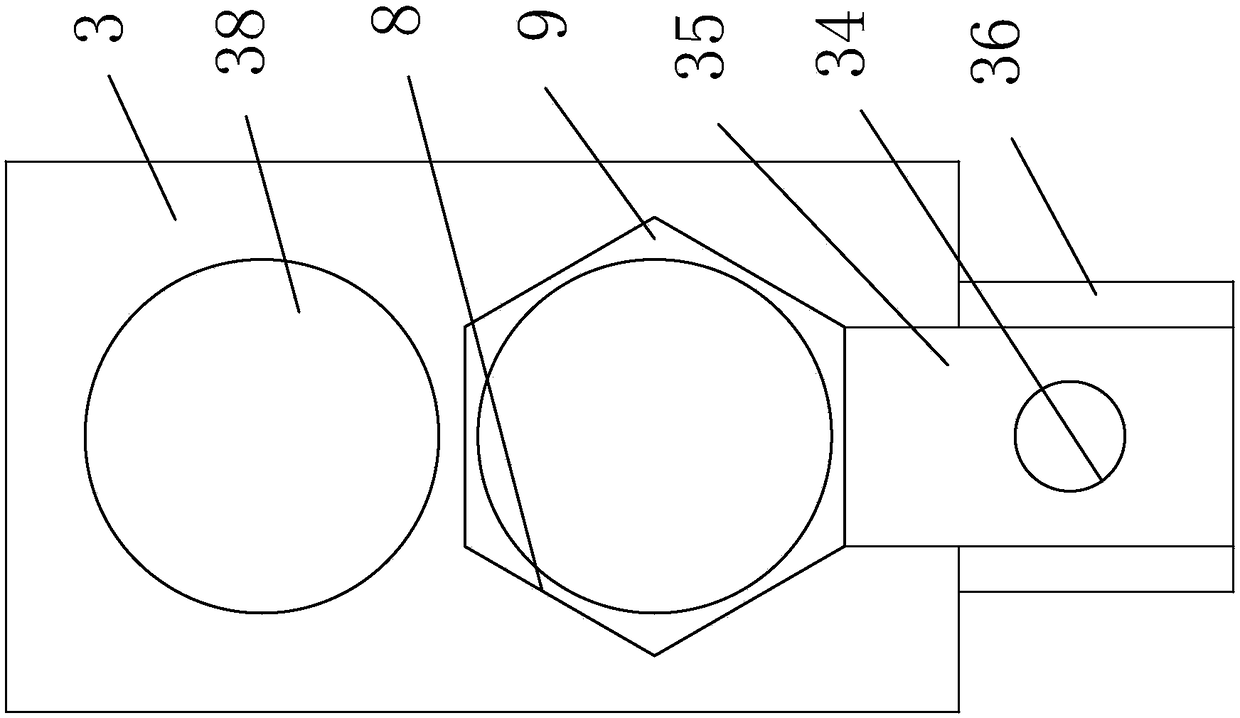

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 Shown: a plasticizing extruder for waste rubber and plastic melted recycled materials, including a barrel 3 with a feed hole 1 and a barrel heating device 2, two screw push rods with screw blades 4, two screw pushers The push rod rotation driving device is arranged at the front end of the cylinder body 3 and is provided with the front sliding hole 5 and the front mounting plate 7 of the front sliding column 6 located in the front sliding hole 5, and is arranged at the rear end of the cylinder body 3 and is provided with the rear sliding hole 8 and the rear mounting plate 10 of the rear sliding column 9 located in the rear sliding hole 8, the filter discharge device arranged at the front end of the cylinder body 3, the material distribution device arranged at the front end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com