Textile bobbin

A bobbin and bobbin technology, applied in the field of textile bobbins, can solve problems such as production accidents and bobbins that are easy to fly out, and achieve the effects of avoiding production accidents, convenient use, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

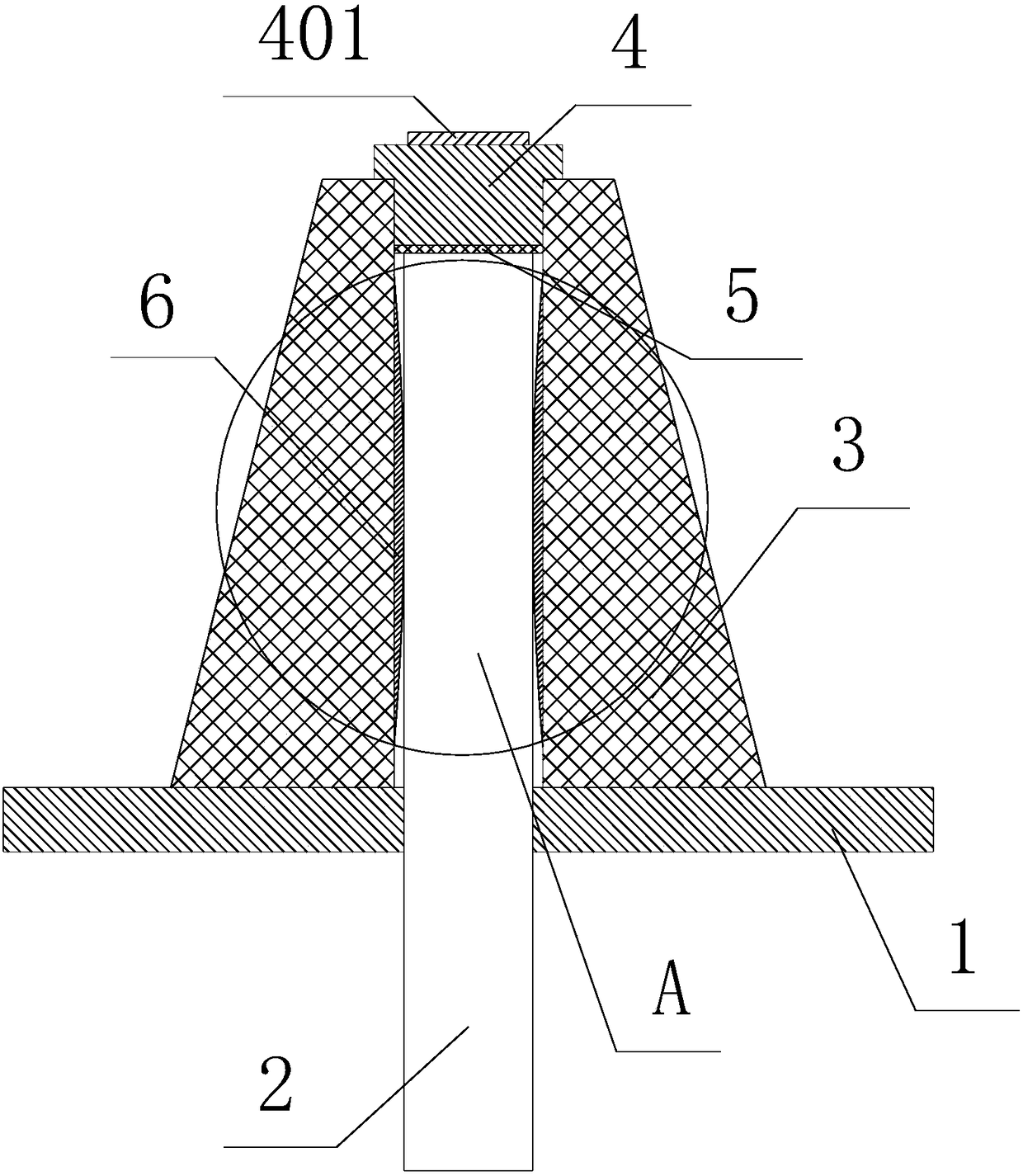

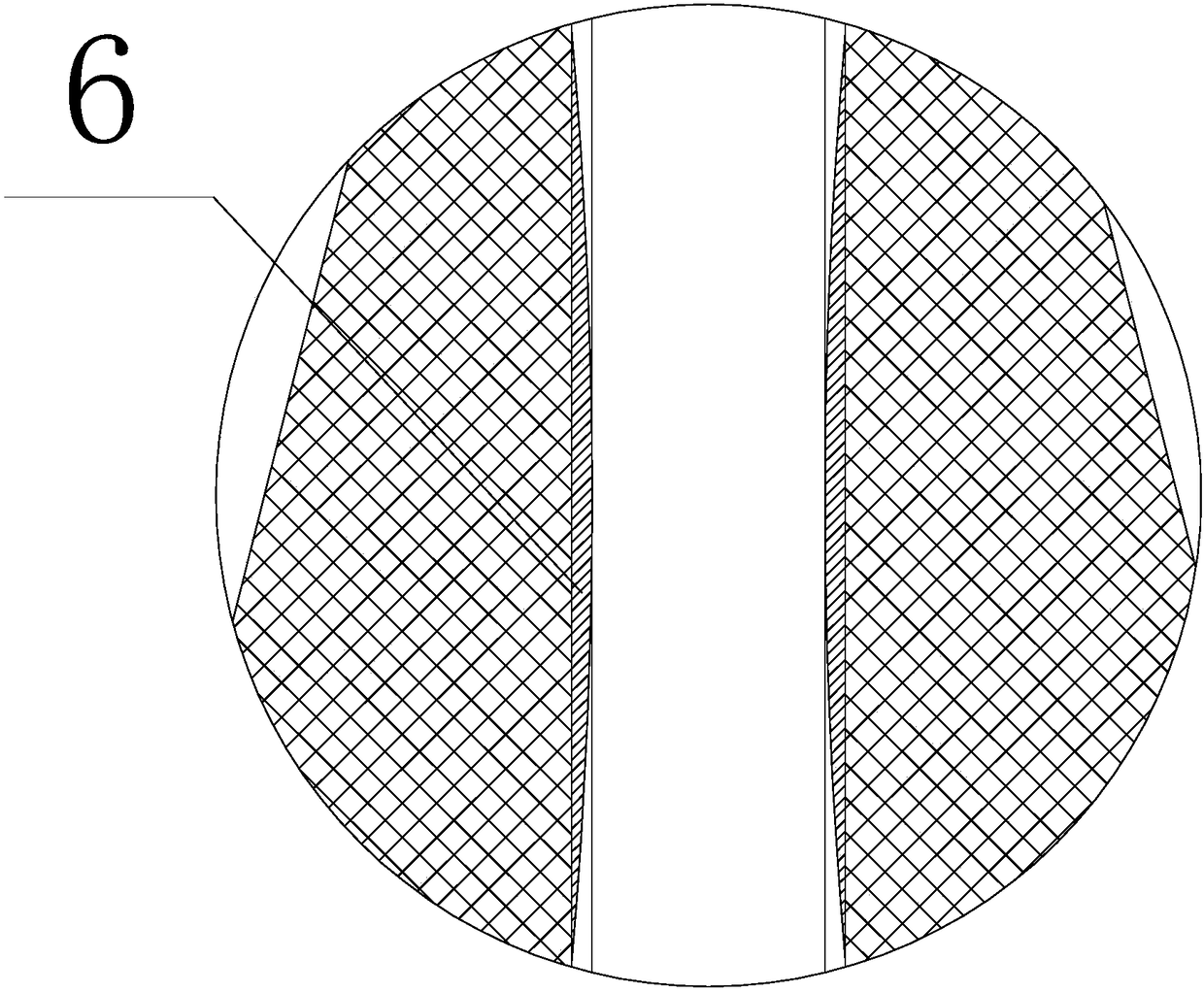

[0018] refer to figure 1 and figure 2 , the present invention provides a textile bobbin, comprising a support plate 1, a rotating shaft 2, a tube body 3, a knob 4, a rubber gasket 5 and a shrapnel 6, the rotating shaft 2 runs through the support plate 1 and extends into the tube body 3, and the tube body 3 Placed on the upper end of the support plate 1, the elastic piece 6 is evenly connected inside the tube body 3, and the elastic piece 6 is set on the rotating shaft 2; the upper end of the tube body 3 is connected to the knob 4, and a rubber gasket 5 is provided between the knob 4 and the rotating shaft 2 to prevent the rotating shaft 2 It is in direct contact with the knob 4 to reduce wear and increase the service life; the pipe body 3 and the knob 4 are connected by right-handed threads, and a strip-shaped protrusion 401 is provided on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com