Masonry beam deformation monitoring system and monitoring and forewarning method based on Hopfield neural network

A neural network and deformation monitoring technology, applied in biological neural network models, neural architectures, earthwork drilling and production, etc., can solve problems such as reduced efficiency of the downhole monitoring system, deformation of the roof triangular block area, and reduced possibility of prediction and early warning. It is not easy to achieve Electronic signal interference, small environmental impact, high degree of anti-electromagnetic interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

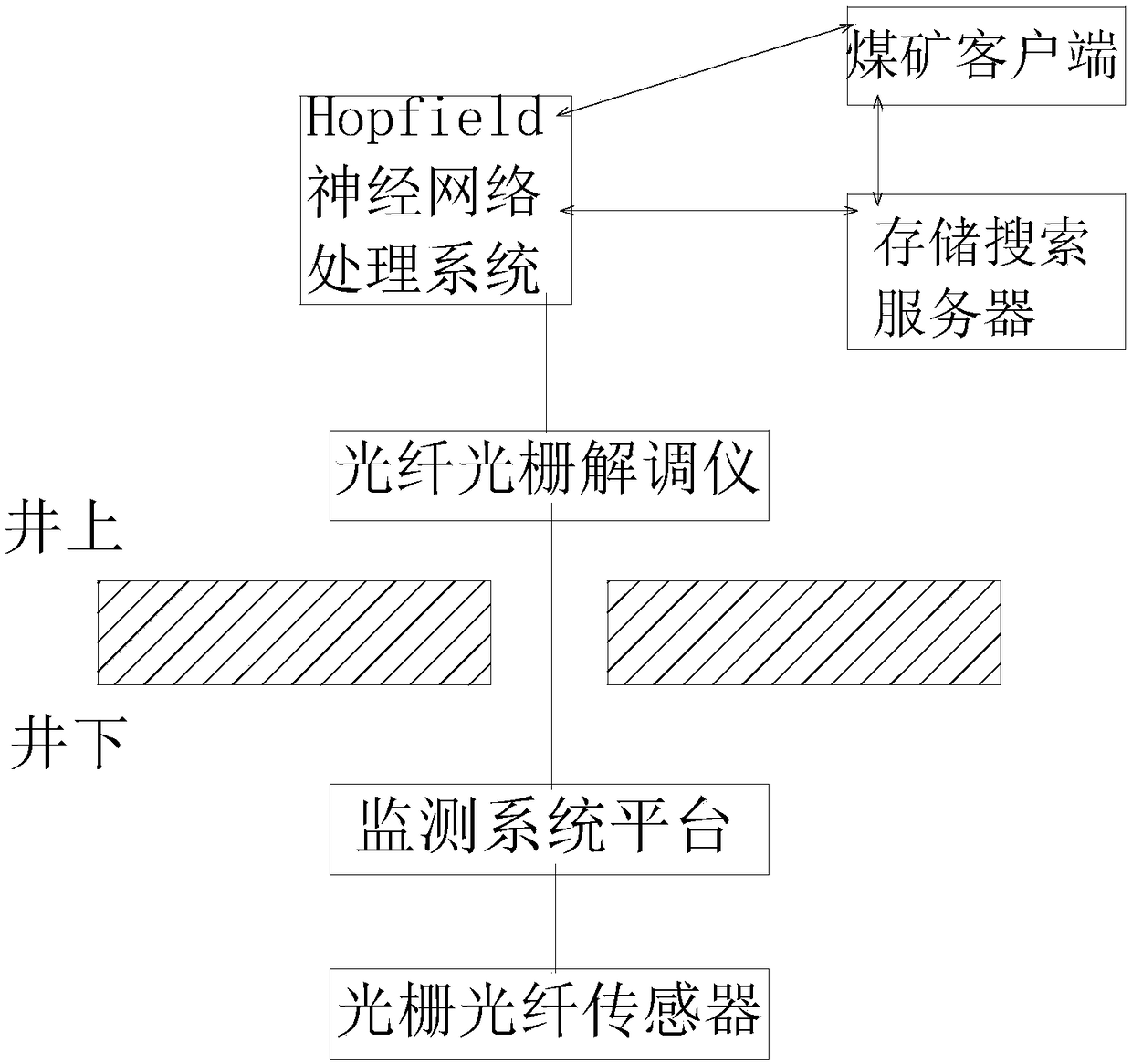

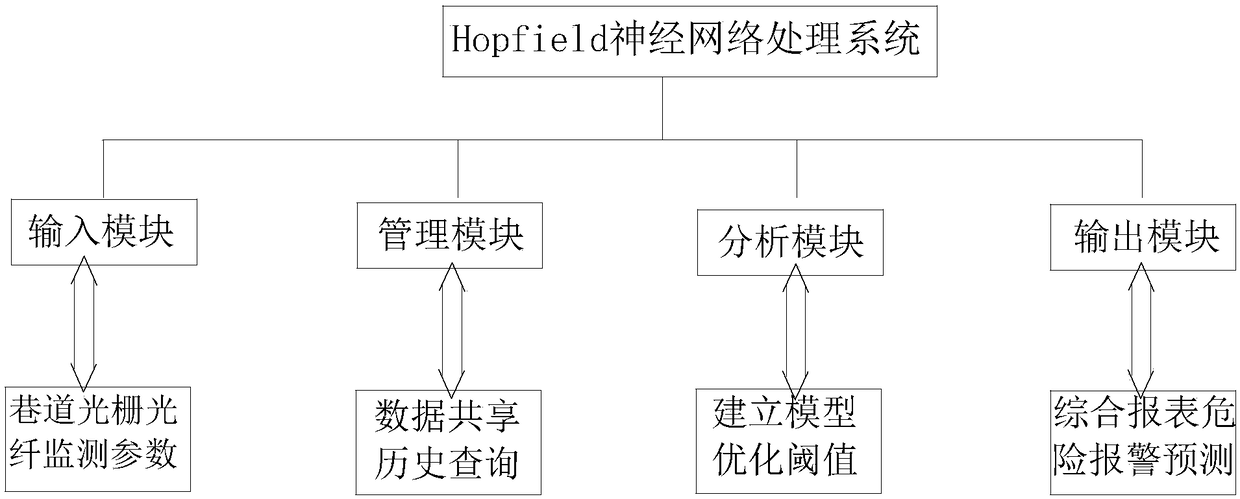

[0041] Such as figure 1 As shown, a masonry beam deformation monitoring system based on Hopfield neural network, including a grating fiber optic sensor installed at each monitoring point in the roadway and a fiber grating installed on the well and communicated with the grating fiber optic sensor through the downhole monitoring system platform The demodulator, the signal output end of the fiber grating demodulator is connected to the Hopfield neural network processing system, and the Hopfield neural network processing system interacts with the storage search server information, wherein:

[0042] The grating optical fiber sensor is used to collect the data of the stress monitoring point and transmit it to the downhole monitoring system platform; the downhole monitoring system platform is used to collect the data from the grating optical fiber sensor and transmit i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com