Turbine capable of maintaining and adjusting turbine guide vane intelligently

A technology for intelligent maintenance and water turbines, applied in the direction of machines/engines, mechanical equipment, hydroelectric power generation, etc., can solve the problems of reducing the sealing effect of guide vanes, easily damaging the surface of guide vanes, and difficult to guarantee, so as to save adjustment and maintenance time and be novel Sexuality and creativity are huge, application and ability to achieve great effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

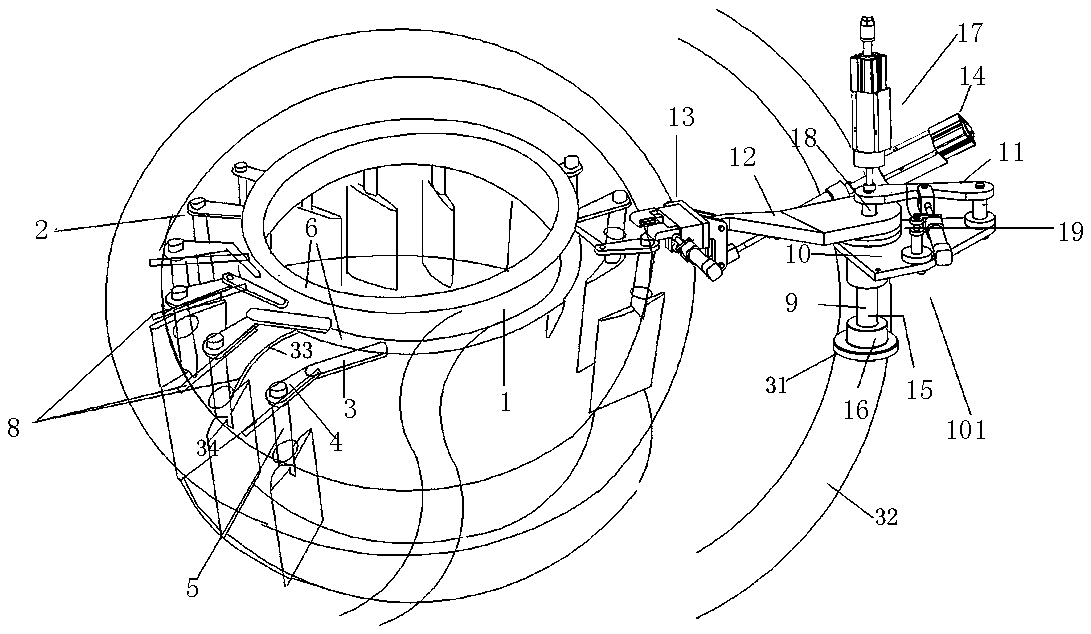

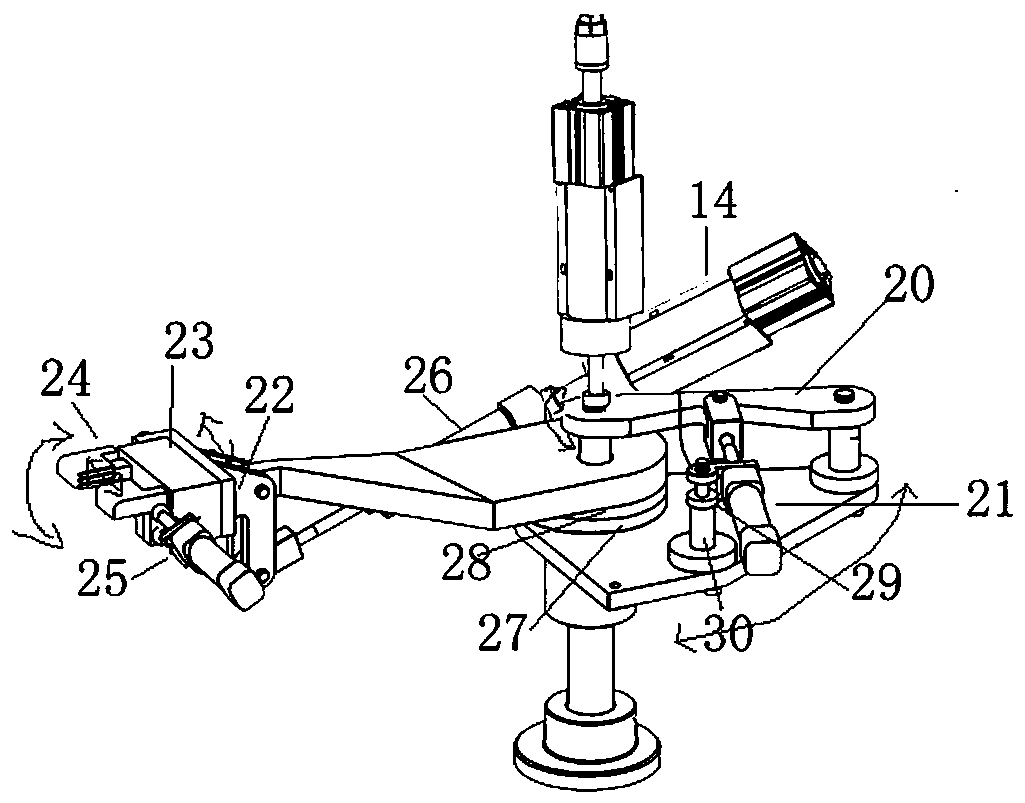

[0020] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is done as preferred specific description:

[0021] Such as Figure 1-2 As shown, a water turbine for intelligently maintaining and adjusting the guide vanes of the water turbine includes a main body of the water turbine. The main body of the water turbine includes a main shaft part and a control wheel part. The wheel components include a control ring, a top cover, a guide vane, and a guide vane arm. This is the prior art and will not be described in detail here. Among them: the top ring piece (1) at the top of the draft tube, the top ring piece can be connected with the control ring It can be integrated or set separately. The guide vane arm (2) includes a connecting plate (3), a guide vane connecting rod (4), and a guide vane shaft (5). The tail end of the connecting plate is fixed on the control ring (6), and the head The guide vane connecting rod is hinged at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com