Water-turbine generator set guide vane water leakage detecting method and system

A technology for generating sets and detection methods, which is applied to hydroelectric power generation, engine components, machines/engines, etc., and can solve problems such as errors and inaccuracies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

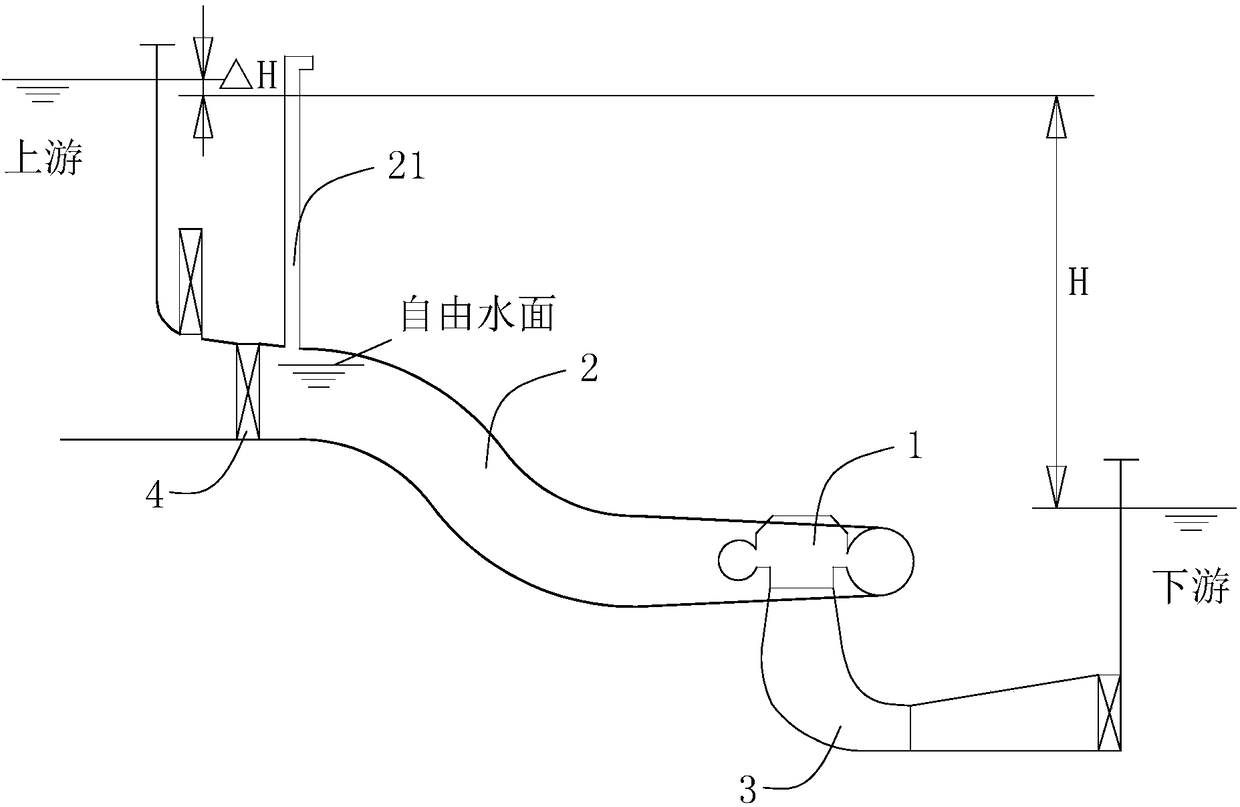

[0022] The following will be figure 1 The hydro-generator set shown is taken as an example, and the method and system for detecting water leakage of the guide vane of the hydro-generator set according to the present invention will be further described in detail. see figure 1 , the guide vane 1 of the hydroelectric generator set is installed between the inlet pipe 2 and the tail water section 3, the front end of the water inlet pipe 2 communicates with the upstream through the fast gate 4, the tail water section 3 communicates with the downstream, and the water inlet pipe 2 is free Ventilation holes 21 are provided on the upper side of the water surface to communicate with the outside world, where H represents the water level difference between the upstream and downstream, and ΔH represents the change in water head caused by the opening and closing of the water inlet pipe 2 . The flow path leveling device is installed at 2 places of the water inlet pipe. The function of the fl...

Embodiment 2

[0037] In this embodiment, on the basis of Embodiment 1, in step 3), a step including calculating the water leakage of the guide vane under the rated water head according to formula (2) is further added;

[0038] Q r =Q 0 (H r / H 0 ) 0.5 (2)

[0039] In formula (2), Q r is the water leakage of the guide vane under the rated water head, H r is the rated water head, H 0 is the time point t when the flow channel leveling device is closed 0 The pressure head before and after the guide vane.

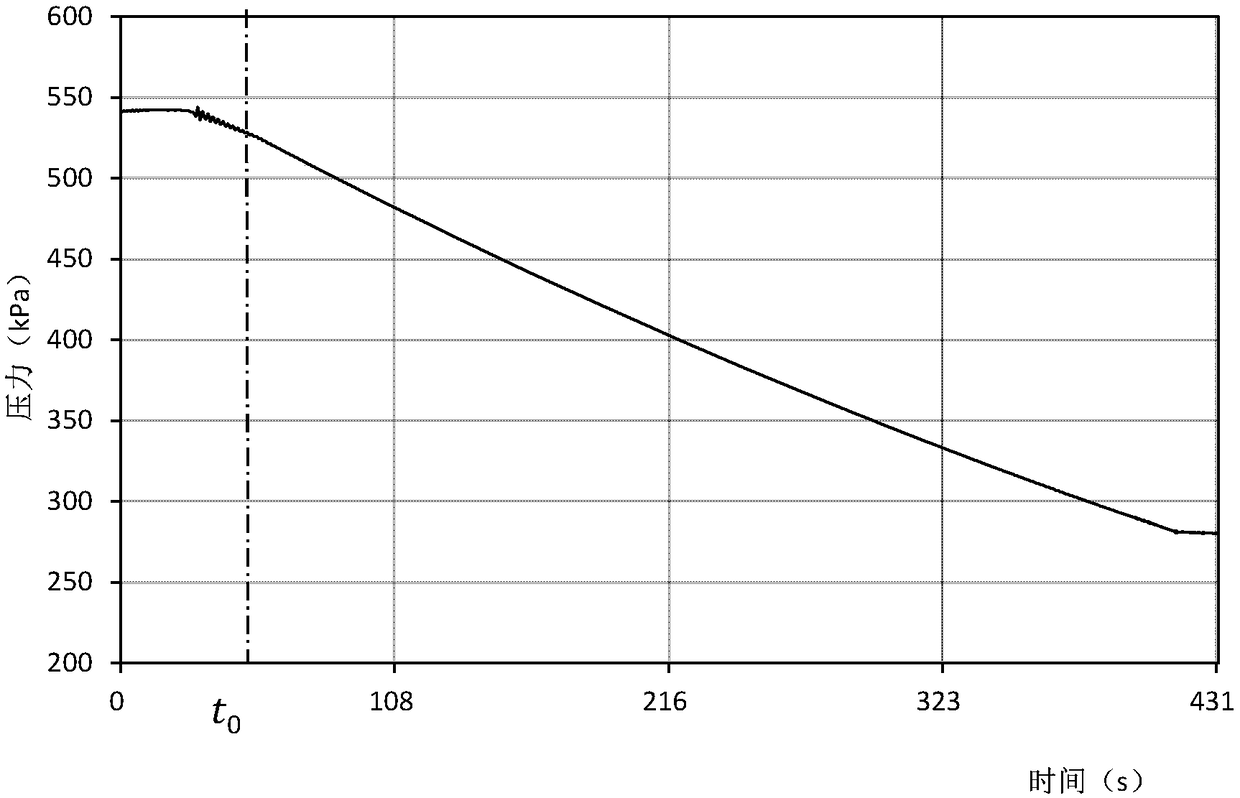

[0040] In this embodiment, when testing, the upstream water level is 248.75m, the downstream water level is 190.55m, and the pressure difference from the center of the water inlet gate to the upstream water level is 32m; t 0 The water level of the vent hole at all times is 246.629m, and the pressure difference between the center of the inlet gate and the water level of the vent hole is 29.88m, then t 0 The water leakage of the gate at all times is 3.37% of the water leakage of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com