Measuring device for measuring adhesion of surface icing of material

A measurement device and adhesion technology, applied in the field of measurement, can solve the problems of limited size range of the sample to be tested, complex test system, low precision of test methods or equipment, etc., and achieve high test accuracy, controllability and precision High performance with excellent controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

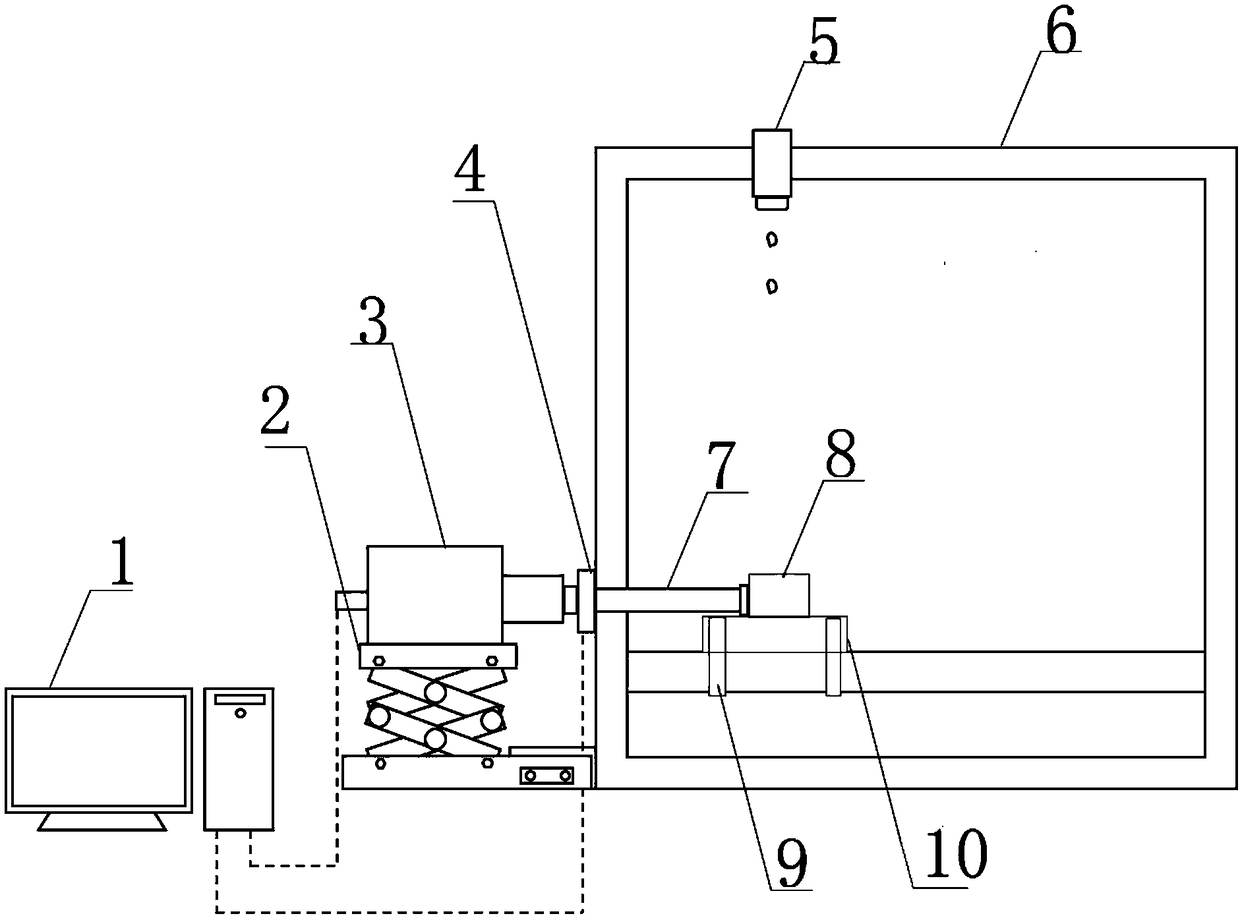

[0040] Such as figure 1 As shown, the material surface adhesion test equipment consists of 1 computer data acquisition module, 2 liftable fixed platform, 3 stepper motor, 4 load cell, 5 external water gun, 6 environmental box, 7 drive shaft, 8 icing sleeve , 9 fixed fixtures, 10 samples to be tested.

[0041] The sample to be tested is a 55mm×55mm×5mm steel plate and a hydrophobic coated plate sample.

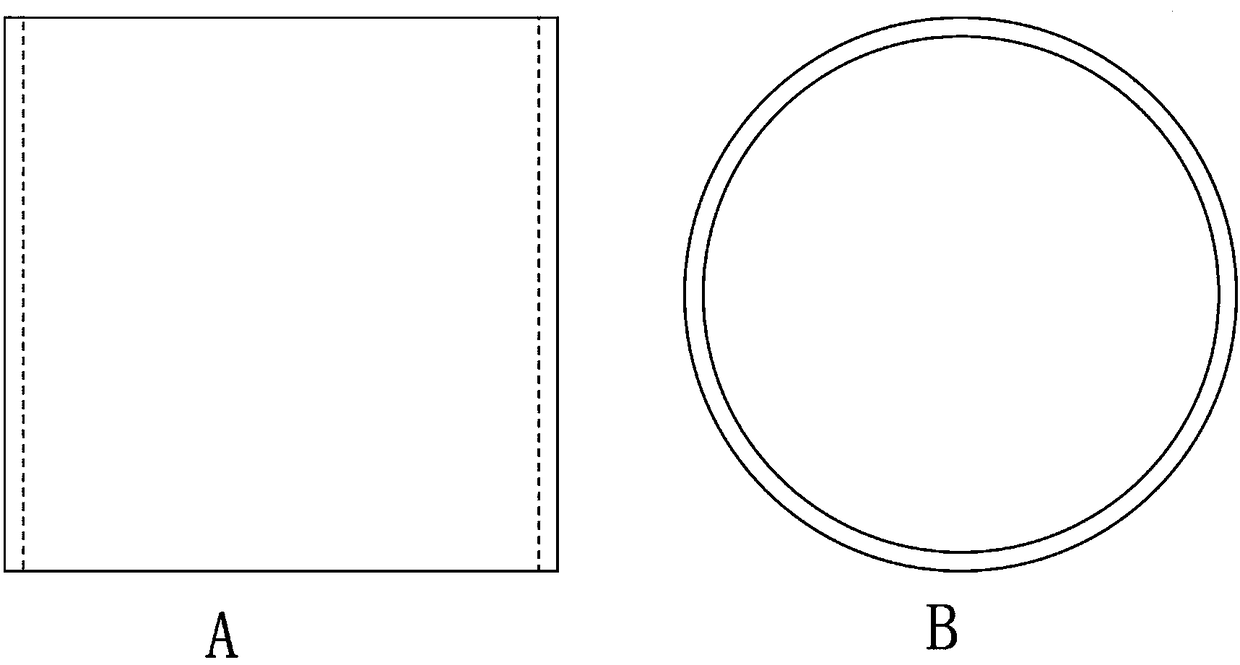

[0042] figure 2 The material of the icing sleeve shown is PVC, the size is Φ30mm, the height is 30mm, and both ends are open, and the icing sleeve is placed on the sample to be tested.

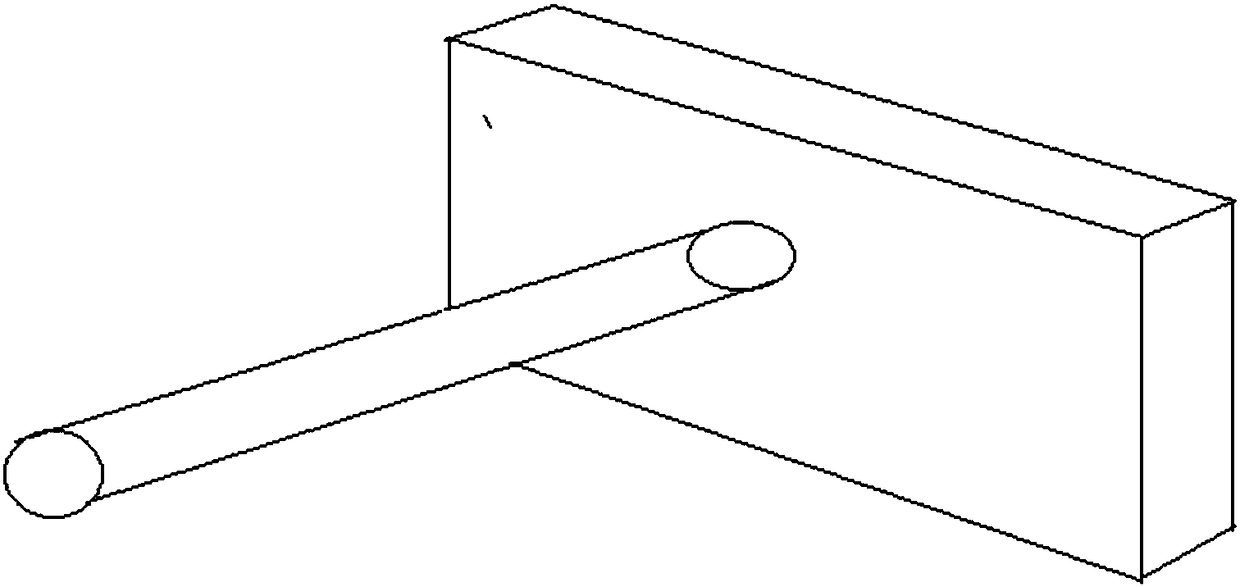

[0043] The transmission shaft is made of stainless steel. image 3 The shape of the contact part between the transmission shaft and the icing sleeve is shown as a cuboid, and the specific size is 30mm×15mm×6mm.

[0044] The test range of the load cell is 0-100kg, and the test accuracy is 0.0001kg.

[0045] The opening of the fixing fixture is adjustable, and the sample to be tested in this ...

example 1

[0055] Example 1 test results are shown in the table below:

[0056]

Embodiment 2

[0058] Such as figure 1 As shown, the material surface adhesion test equipment consists of 1 computer data acquisition module, 2 liftable fixed platform, 3 stepper motor, 4 load cell, 5 external water gun, 6 environmental box, 7 drive shaft, 8 icing sleeve , 9 fixed fixtures, 10 samples to be tested.

[0059] The samples to be tested are 55mm×55mm×6mm steel plates and hydrophobic coated plate samples.

[0060] figure 2 The material of the icing sleeve shown is stainless steel, the size is Φ30mm, the height is 30mm, and both ends are open, and the icing sleeve is placed on the sample to be tested.

[0061] The drive shaft is made of stainless steel, image 3 The shape of the contact part between the transmission shaft and the icing sleeve is shown as a cuboid, and the specific size is 30mm×15mm×6mm.

[0062] The test range of the load cell is 0-100kg, and the test accuracy is 0.0001kg.

[0063] The opening of the fixing fixture is adjustable, and the sample to be tested i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com