Method and device for testing metal semiconductor interface recombination current density

A metal semiconductor, current density technology, applied in the direction of current density measurement, etc., can solve the problems of inaccurate test results, low accuracy, damage to the surface state of non-metallic areas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

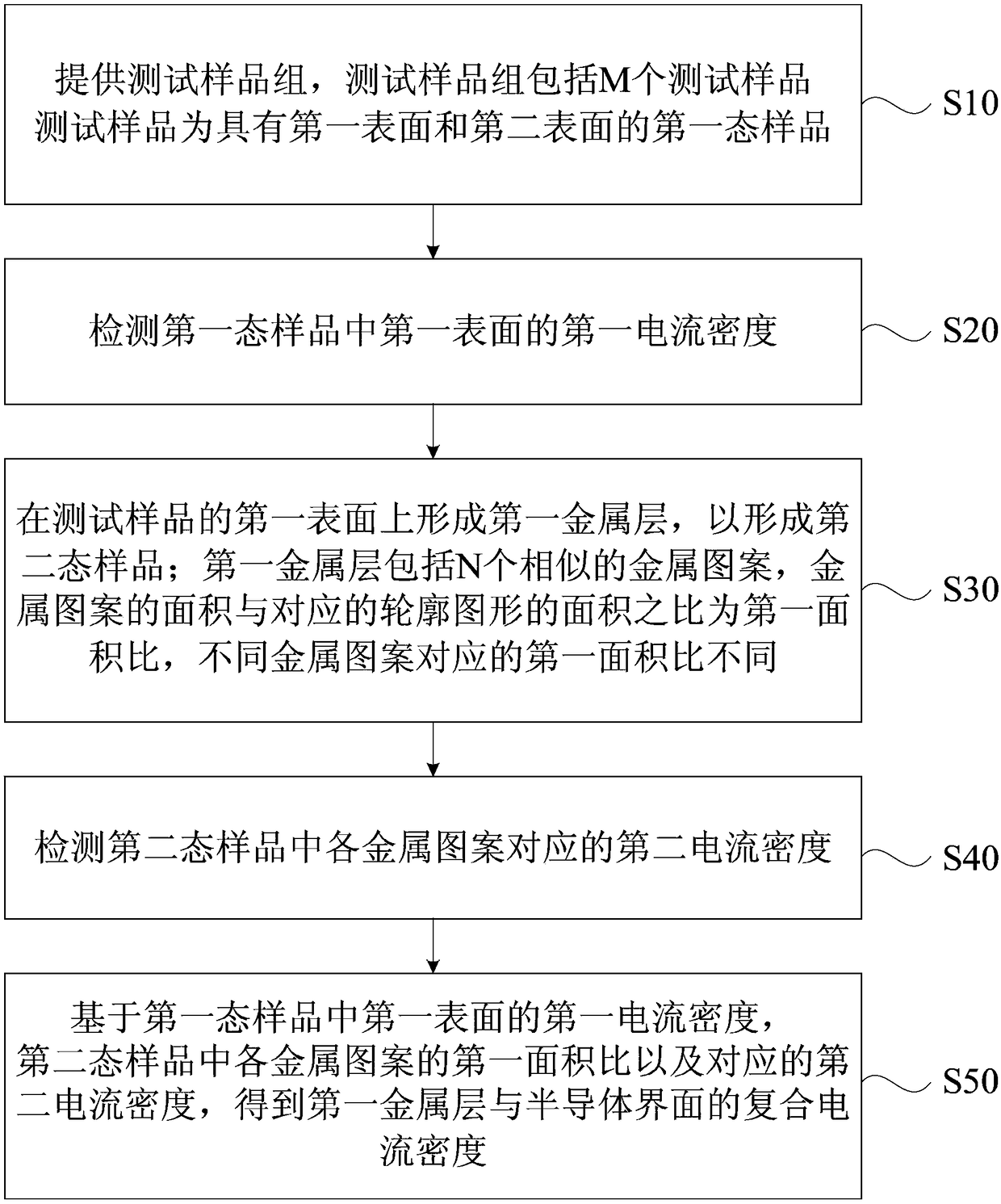

[0036] figure 1 It is a flowchart of a test method for recombination current density at a metal-semiconductor interface provided by Embodiment 1 of the present invention. see figure 1 , an embodiment of the present invention provides a method for testing the recombination current density at a metal-semiconductor interface, including:

[0037] S10. Provide a test sample group, the test sample group includes M test samples, the test sample is a first-state sample having a first surface and a second surface, wherein the test sample is a semiconductor sample, and the first One surface is the side where the N region is located in the P-type substrate, and the second surface is the side where the P region is located in the P-type substrate; or, the first surface is the side where the P region is located in the N-type substrate, The second surface is the side of the N-type substrate where the N region is located.

[0038] Wherein, the test sample is a semiconductor sample, includi...

Embodiment 2

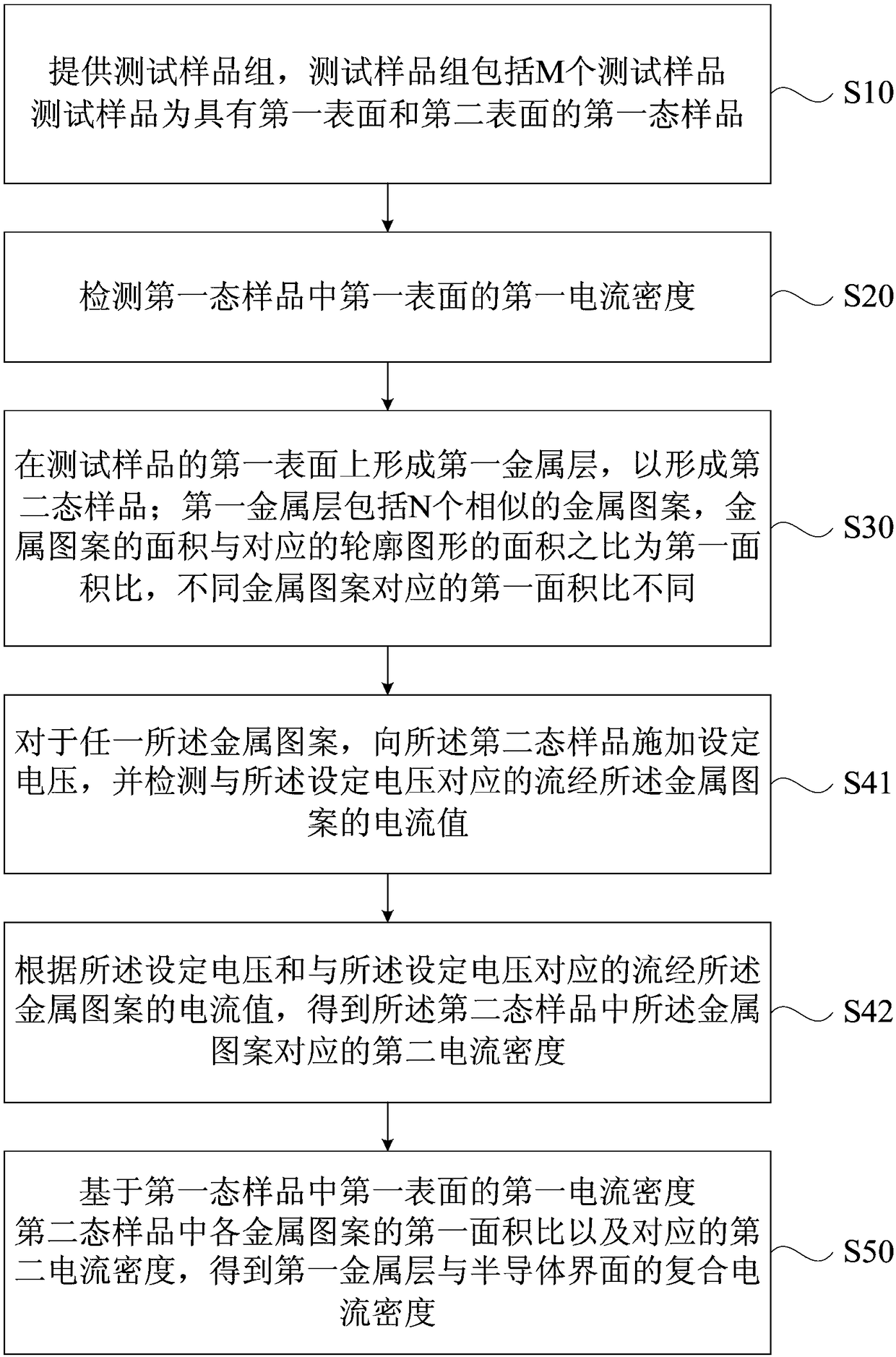

[0063] image 3 It is a flow chart of a test method for recombination current density at a metal-semiconductor interface provided by Embodiment 2 of the present invention. This embodiment is a specific example of the first embodiment. For example, see image 3 , the metal-semiconductor interface recombination current density test method includes:

[0064] S10. Provide a test sample group, the test sample group includes M test samples, the test sample is a first-state sample having a first surface and a second surface, wherein the test sample is a semiconductor sample, and the first One surface is the side where the N-region in the P-type substrate is located or the side where the P-region is located in the N-type substrate, and the second surface is the side where the P-region is located in the P-type substrate or the side where the N-region is located in the N-type substrate side.

[0065] S20. Detect a first current density on the first surface in the first state sample....

Embodiment 3

[0092] Figure 5 It is a schematic structural diagram of a current density testing device provided in Embodiment 3 of the present invention. In the method for testing the recombination current density at the metal-semiconductor interface in the above embodiment, the current density testing device is used to detect the second current density corresponding to each of the metal patterns in the second-state sample. see Figure 5 , the current density test device includes a test platform 1, a flat plate electrode 2, a test probe 3, a current tester 4, a voltage tester 5 and a current and voltage source 6.

[0093] Continue to see Figure 5 , the test platform 1 is used to place the test sample 10; the flat electrode 2 is opposite to the test platform 1, and the flat electrode 2 is separated from the test platform 1 by a set distance to form a test area for accommodating the test sample 10; the flat electrode 2 is set There is a through hole through the plate electrode 2; the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com