Exhaust emission structure

A waste gas emission, square technology, applied in the direction of dispersed particle separation, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of affecting the effect of large flow of waste gas emission, affecting the effect of waste gas dust removal treatment, and the inability to switch gas efficiently, etc., to achieve Improved contact tightness, stable operation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

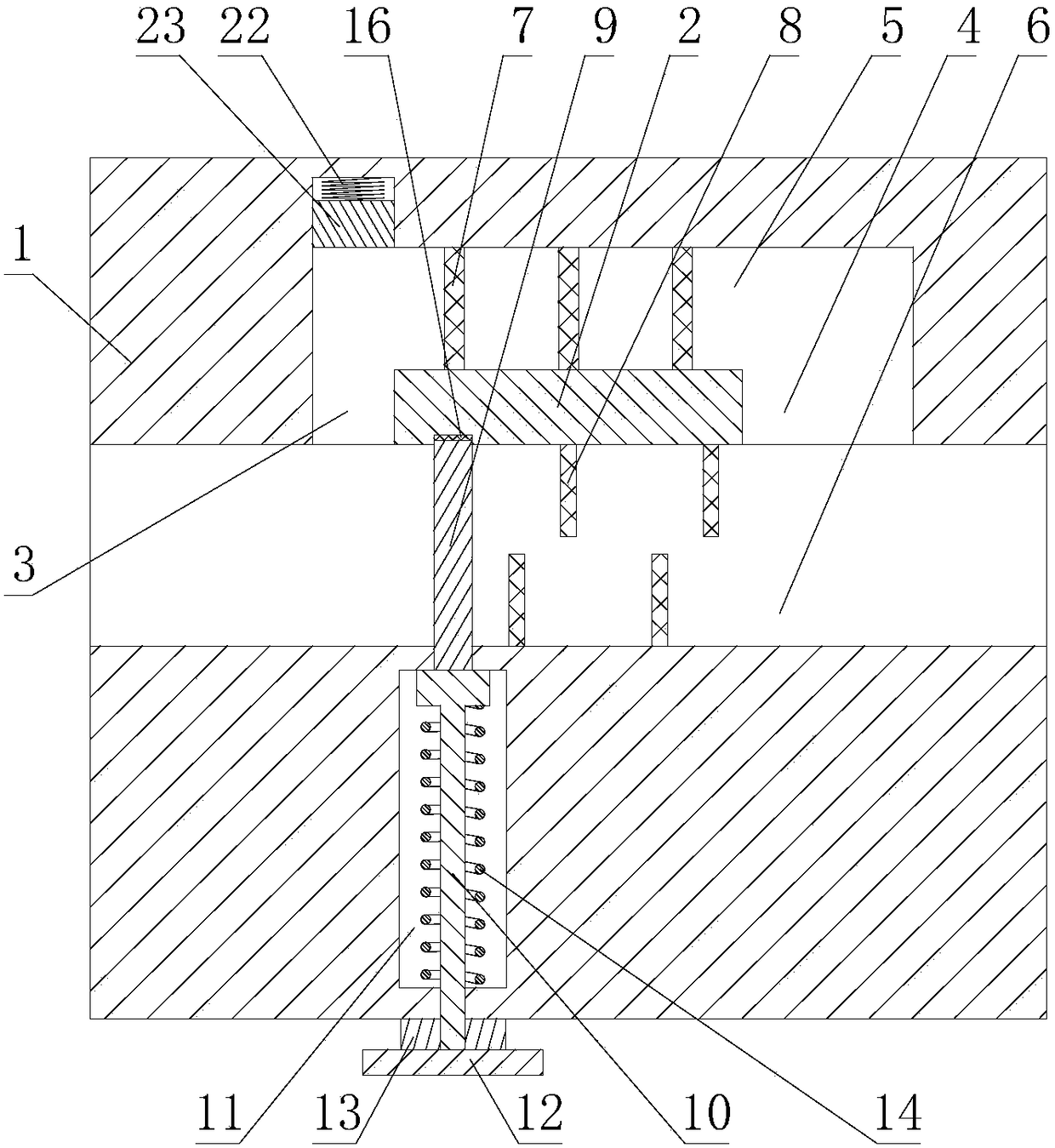

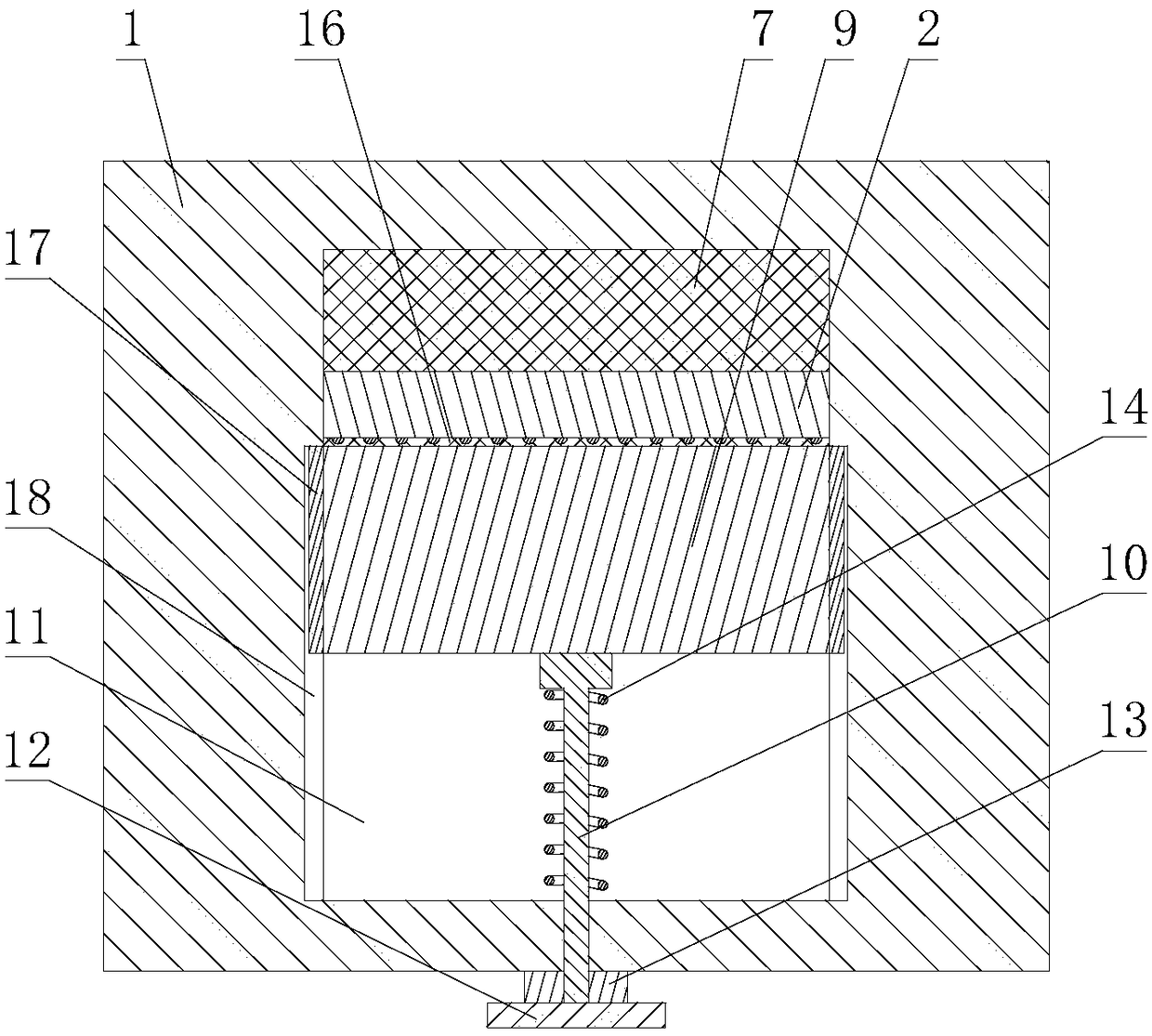

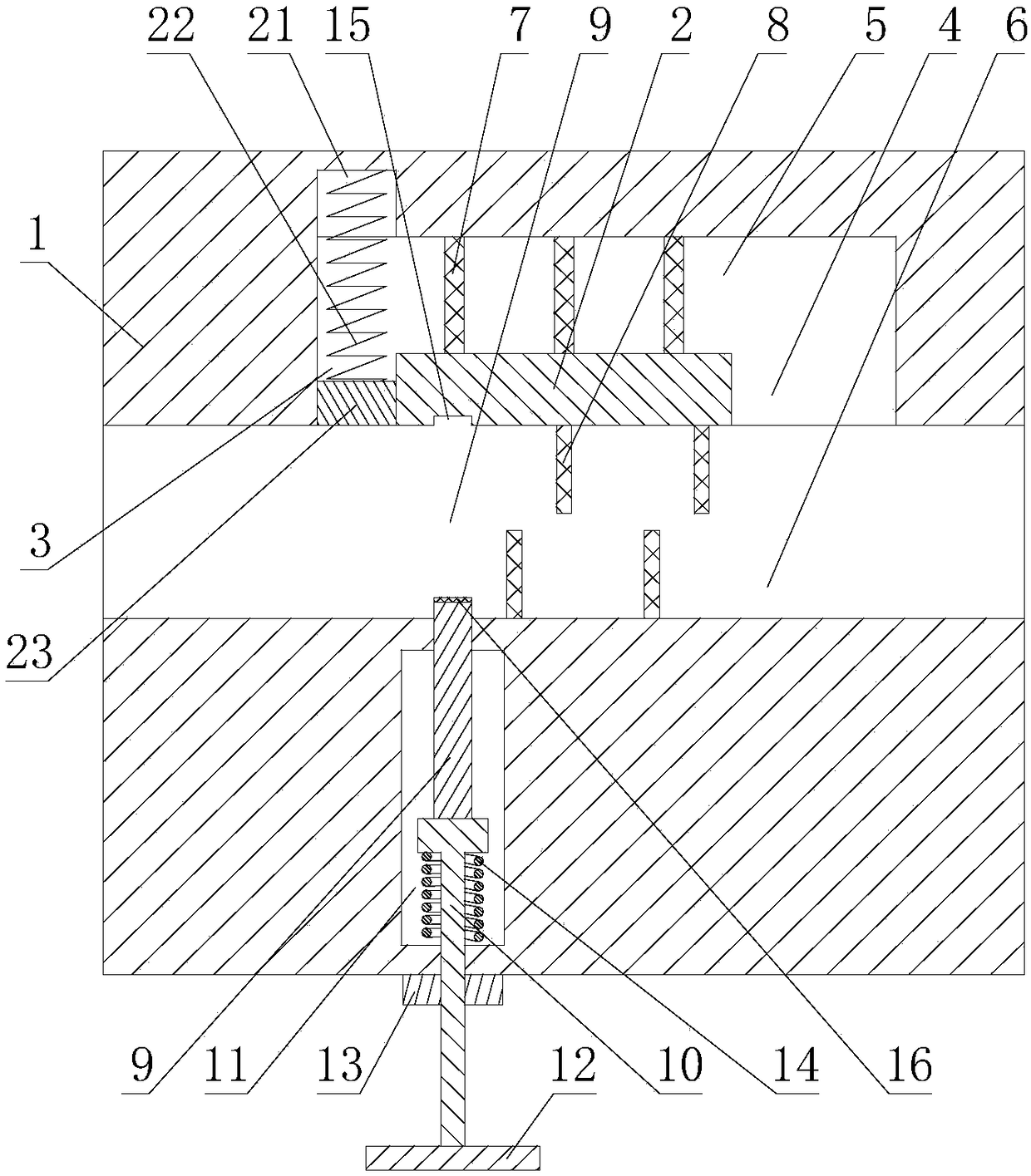

[0033] Such as Figure 1 to Figure 4 As shown, the exhaust gas discharge structure includes a square pipe 1 that is open at both ends of the left and right and is hollowly arranged. A partition 2 is arranged horizontally in the inner cavity of the square pipe 1. The left and right ends of the plate 2 are not connected to the inner wall of the square pipe 1, the left end of the partition 2 and the inner wall of the square pipe 1 jointly form a first port 3, and the right end of the partition 2 and the inner wall of the square pipe 1 jointly form a first opening 3. Two-way port 4;

[0034] The partition plate 2 divides the inner cavity of the square pipe 1 into a relatively independent filter cavity 5 and a discharge cavity 6 located below the filter cavity 5. The filter cavity 5 is provided with a plurality of front and rear direction setting and the area is equal to the first filter cavity 5 cross-sectional area. a filter screen 7;

[0035] The inner wall of the square pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com