Method for high-precision on-line proportional mixing of plurality of liquids

A proportional mixing, high-precision technology, applied in mixing methods, mixers, chemical instruments and methods, etc., can solve the problems of unguaranteed mixing ratio accuracy, limited accuracy improvement, and insufficient control range, and achieve obvious progress and practicability. , high precision, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

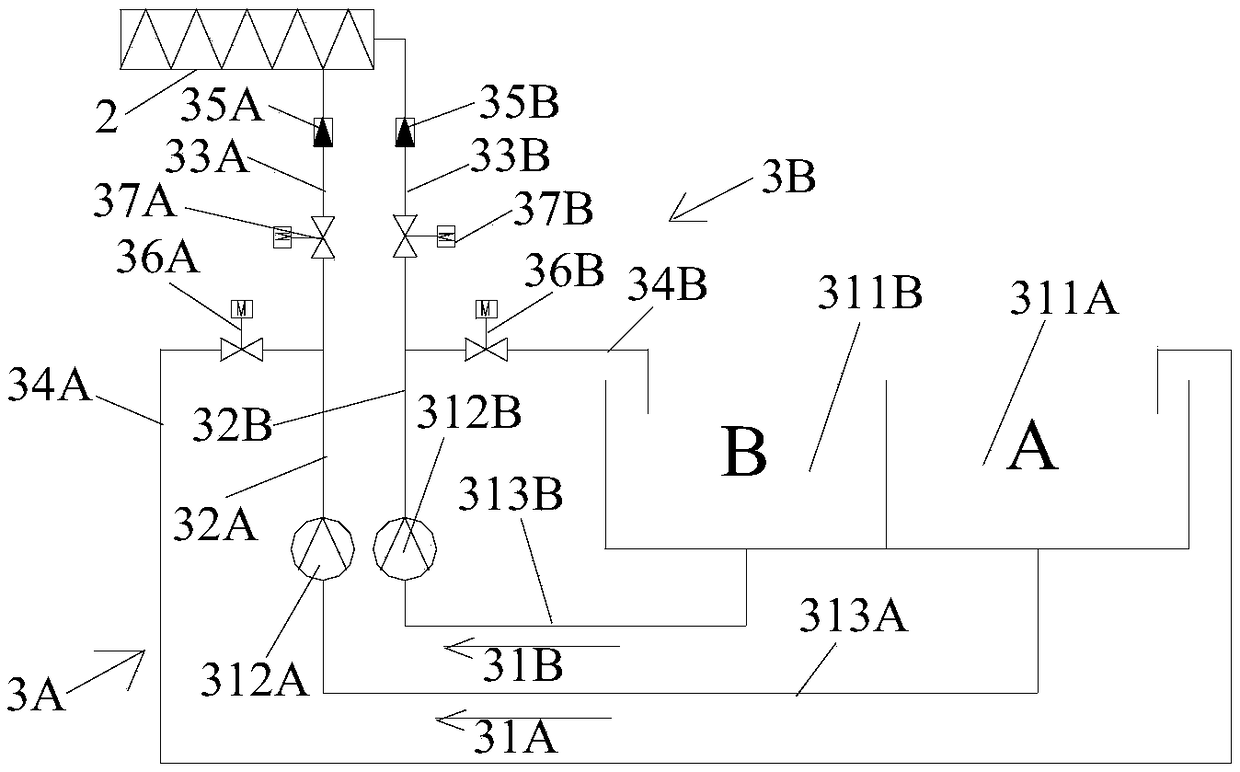

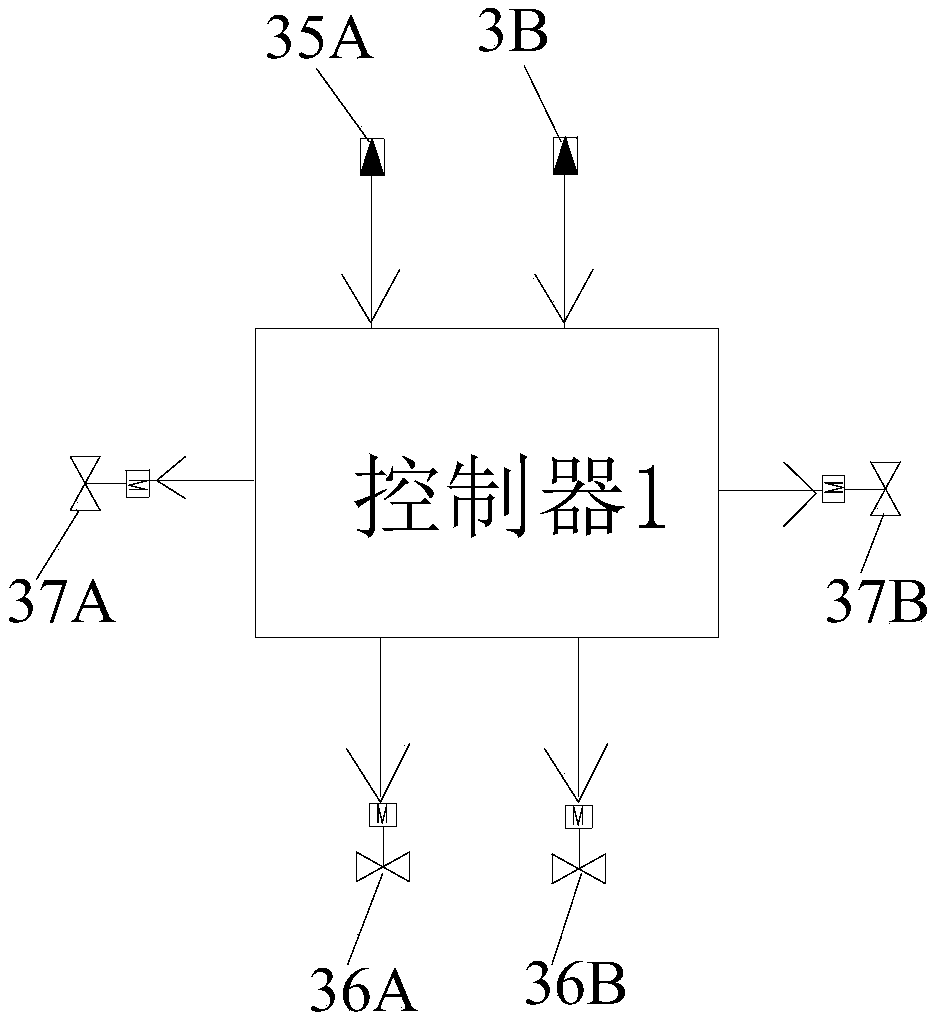

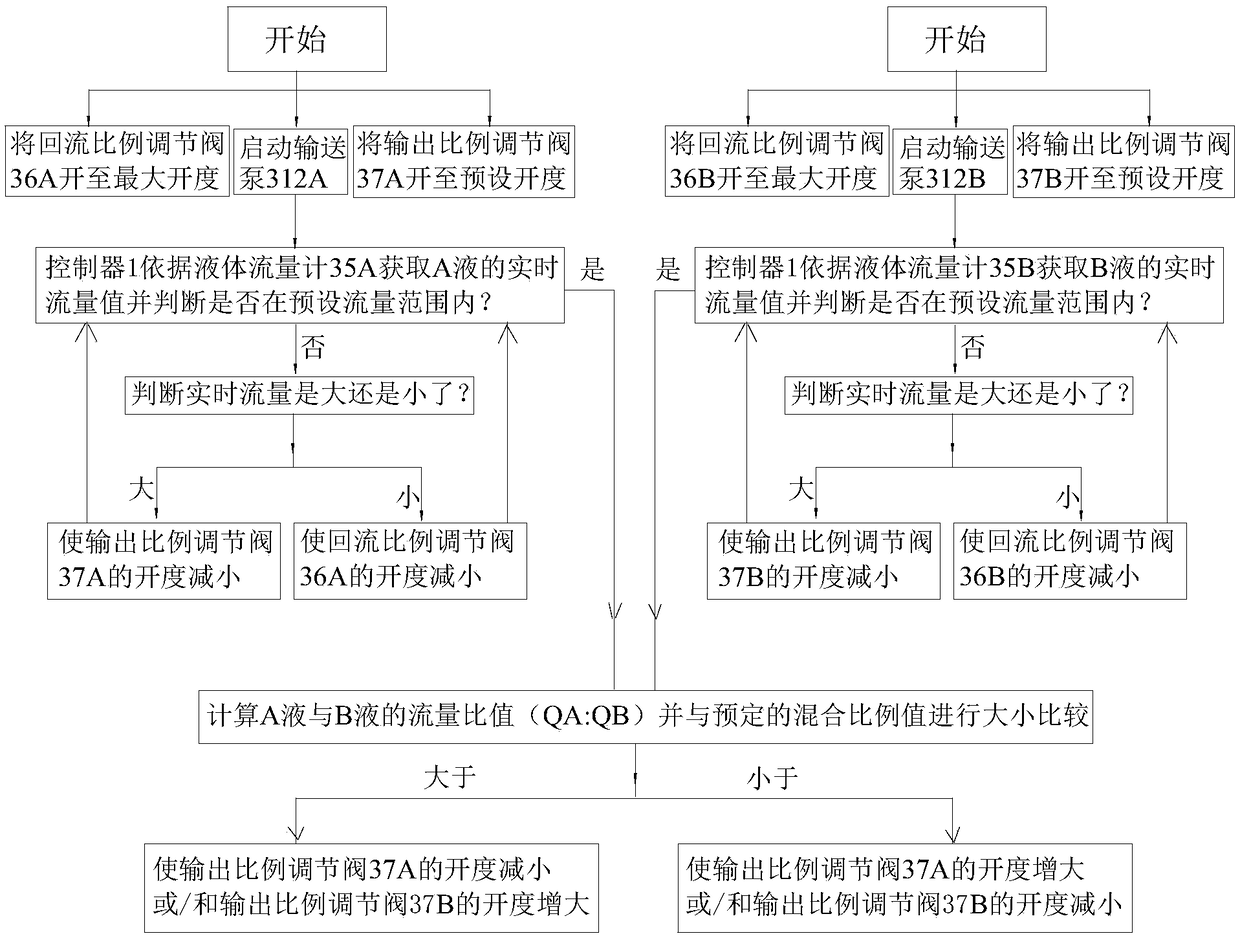

[0023] See figure 1 and figure 2 As shown: the system for realizing multi-liquid online proportional mixing in this embodiment includes a controller 1, a mixing container 2 and 2 liquid output units 3A / 3B (in this embodiment, 2 are taken as an example, but not limited to 2, the specific number Determined according to the type of liquid to be mixed, each liquid to be mixed corresponds to one liquid output unit), each liquid output unit 3A / 3B includes at least a liquid source 31A / 31B and a main delivery pipeline 32A / 32B, in this embodiment The liquid source 31A / 31B includes a liquid storage container 311A / 311B and a liquid delivery pump 312A / 312B. The liquid storage container 311A / 311B is connected to the liquid delivery pump 312A / 312B through an input pipeline 313A / 313B. The output end of the liquid delivery pump 312A / 312B is connected to the head end of the main delivery pipeline 32A / 32B, and the end of the main delivery pipeline 32A / 32B is equally divided into an output pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com