Inspection robot automatically opening and closing equipment cabinet door and control method

A technology of inspection robots and automatic switches, which is applied in the direction of program-controlled manipulators, manipulators, manufacturing tools, etc., can solve problems such as high cost, inconvenient maintenance, and mismatching of closing time and working time, so as to reduce dependence and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following describes the embodiments of the present invention in further detail: it should be emphasized that the embodiments described in the present invention are illustrative rather than restrictive. Therefore, the present invention is not limited to the embodiments described in the specific embodiments. Other implementation manners obtained by those skilled in the art according to the technical solution of the present invention also fall within the protection scope of the present invention.

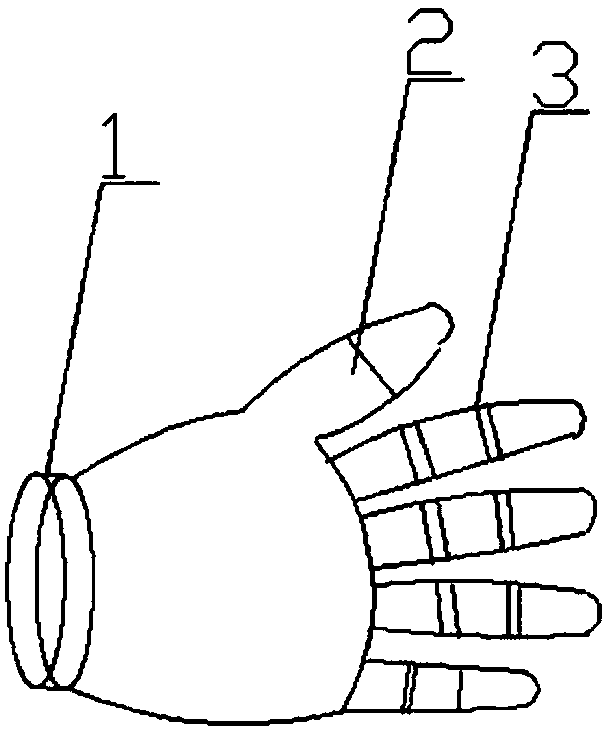

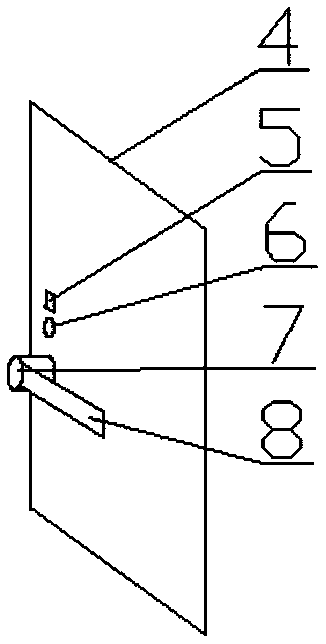

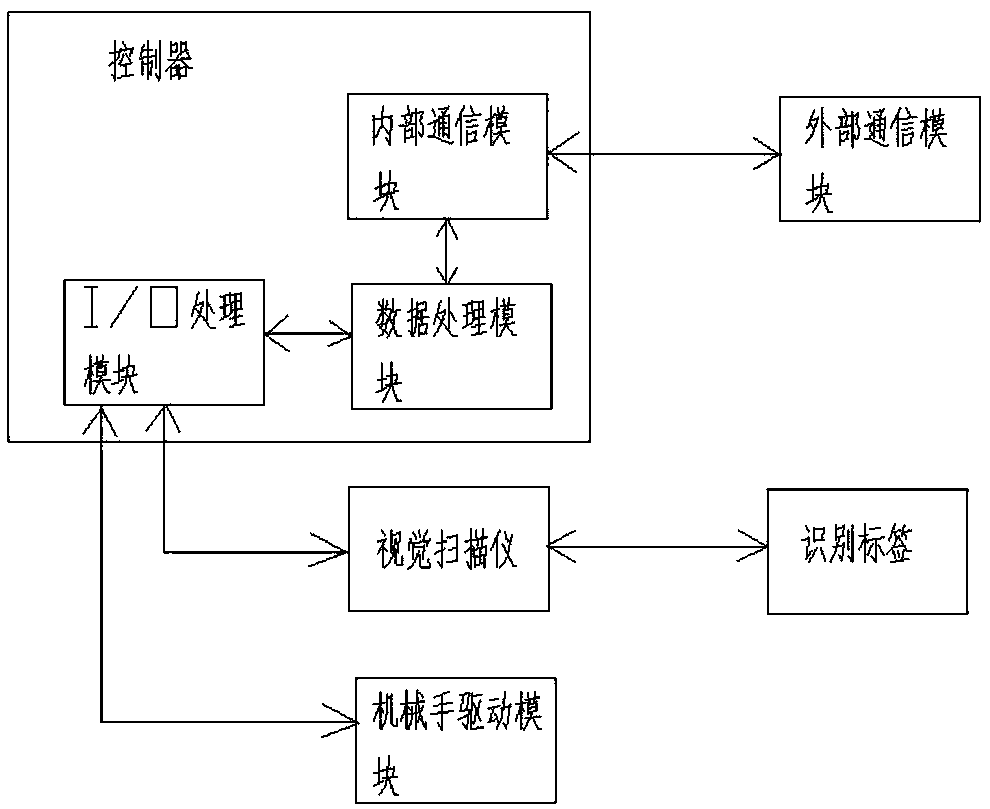

[0038] An inspection robot that automatically opens and closes cabinet doors, such as figure 1 Or as shown in 2 or 3, the robot includes a manipulator with a bowl joint 1, a thumb joint 2 and a four-finger joint 3. The manipulator is connected with a manipulator drive module installed inside the robot, and the space objects around the robot are scanned on the top of the robot. The visual ranging scanning system, the visual ranging scanning system and the manipulator drive module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com