Rewinding machine for heat conduction film

A thermally conductive film and rewinder technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of solid foreign matter in thermally conductive graphite film, poor appearance and performance of thermally conductive graphite film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

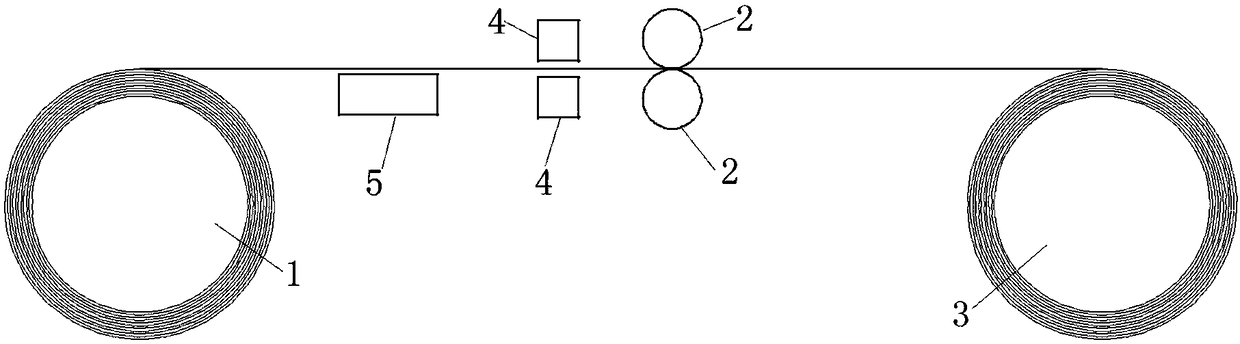

[0034] This embodiment provides a thermally conductive film rewinder, such as figure 1 As shown, it includes a discharging shaft 1, a rewinding shaft 3, and two suction components 4.

[0035] Wherein, the unwinding shaft 1 is parallel to the axis of the rewinding shaft 3 and is arranged at a certain interval. The unwinding shaft 1 is suitable for covering the thermally conductive film roll to be rewinded; The heat-conducting film drawn from the shaft 1 is wound on its outer wall; the rewinding shaft 3 is driven to rotate by the driver to drive the unwinding shaft 1 to rotate. For example, the motor drives the winding shaft 3 to rotate, and the winding shaft 3 drives the unwinding shaft 1 to rotate synchronously with it through the transition effect of the thermally conductive film.

[0036] At least one suction assembly 4 is arranged between the unwinding shaft 1 and the rewinding shaft 3. The suction assembly 4 has at least one suction opening; the suction assembly 4 is used to g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com