A Friction-Plastic Hinge That Makes Structures Nondestructive

A technology of plastic hinges and friction plates, which is applied to building components, building structures, building types, etc., can solve problems such as irreparable, plastic hinge damage, and precise control of energy consumption in difficult structures, achieving the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

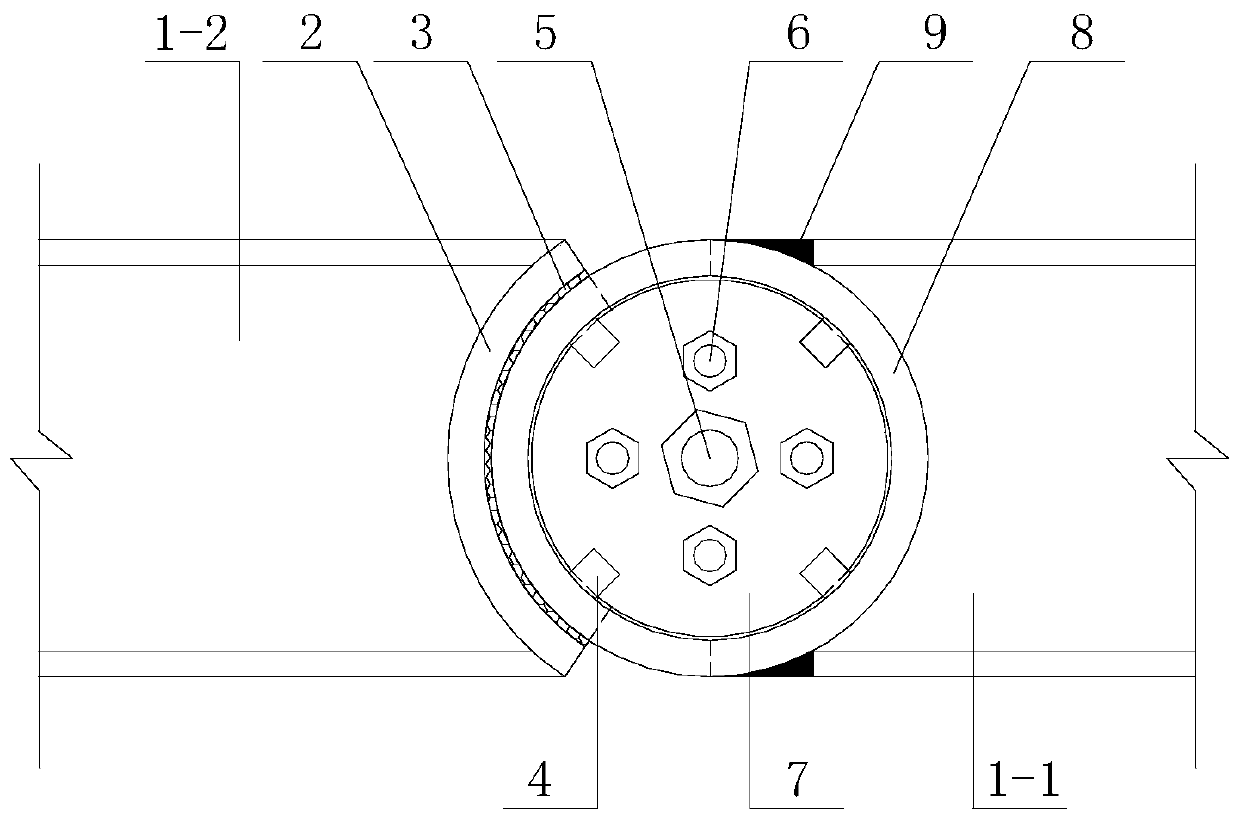

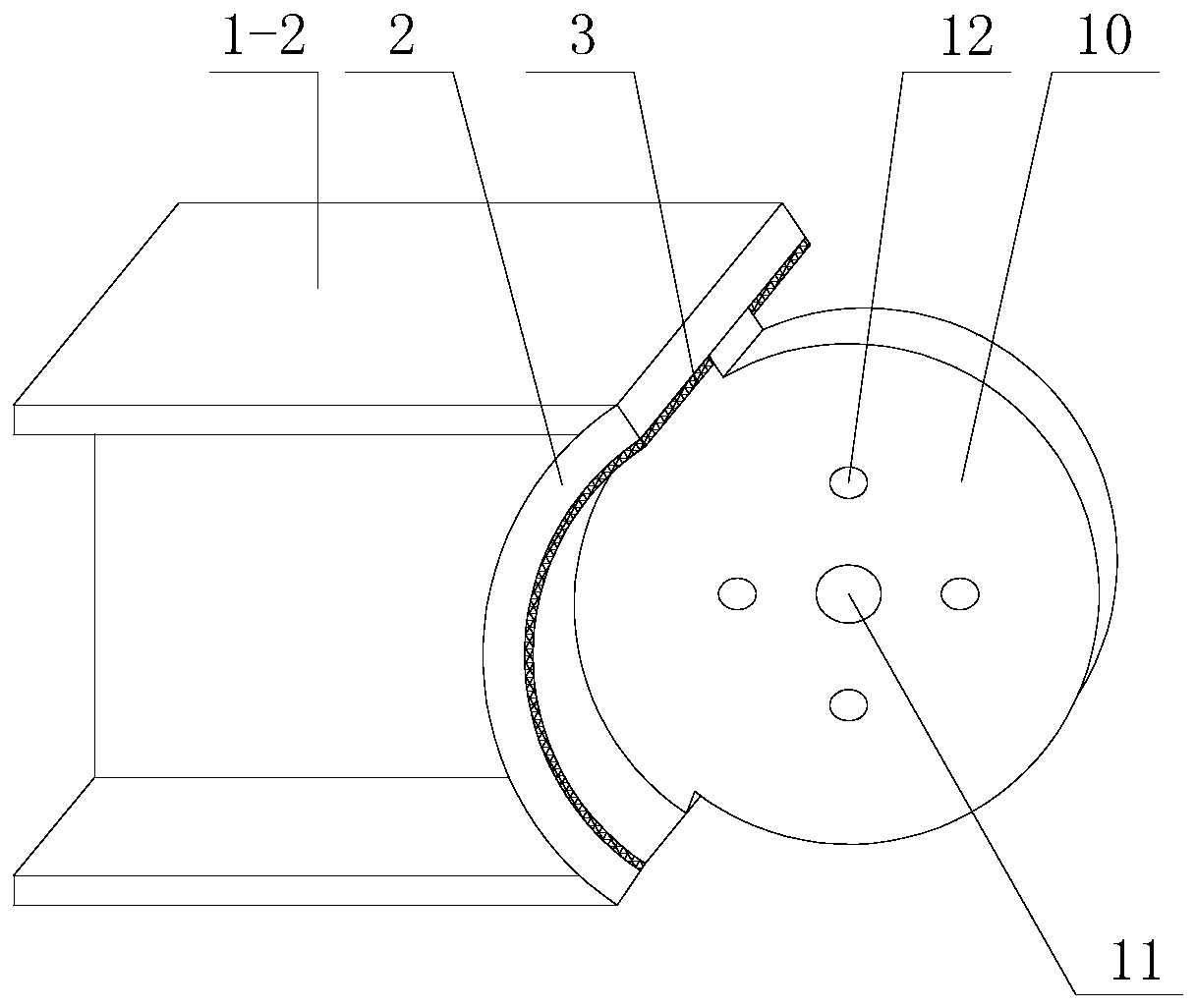

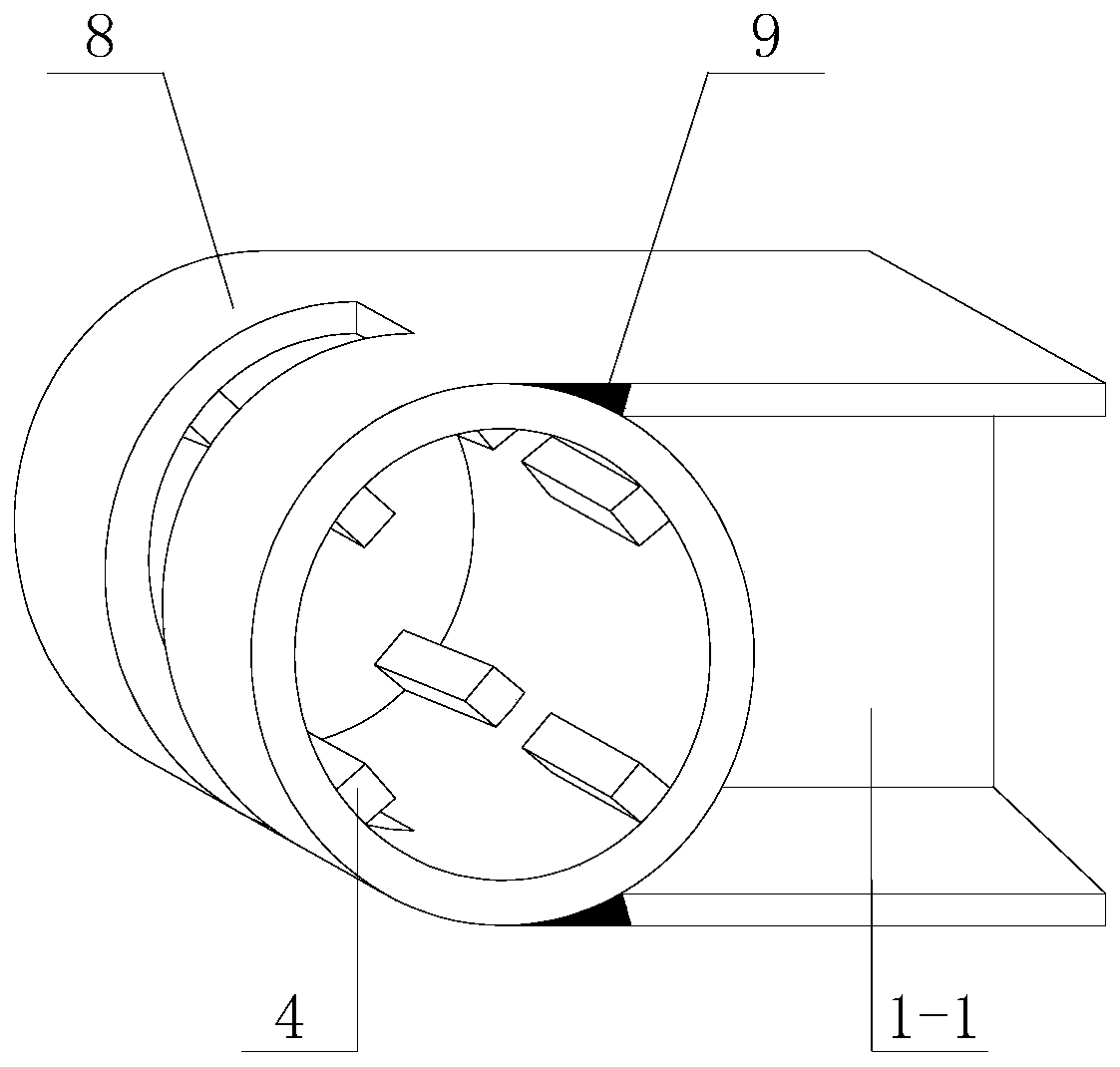

[0012] This is like Figure 1 ~ Figure 2 As shown, the present invention is based on the energy dissipation principle of the friction pendulum shock-isolation bearing, and is designed in combination with the construction method of the automobile braking device. The present invention includes three parts: a basic unit, a rotating unit, and a connecting energy-consuming unit. The basic unit is composed of a circular tube-shaped sealing plate 8, a limit strip 4, and a first steel beam 1-1, wherein the first steel beam 1-1 It is connected with the circular tube-shaped sealing plate 8, and the limit strip 4 is connected with the circular tube-shaped sealing plate 8; the rotating unit is composed of the second steel beam 1-2, the arc-shaped sealing plate 2, the rubber friction material 3, and the rotating single connecting plate 10, the arc-shaped sealing plate 2 is connected with the second steel beam 1-2, the rotating single connecting plate 10 is connected with the arc-shaped sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com