Method and system for pulsed engine water injection

An engine, water injection technology, applied in the direction of engine components, engine operation, engine control, etc., can solve problems such as uneven distribution, unrealized water injection potential, and lack of charging air cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

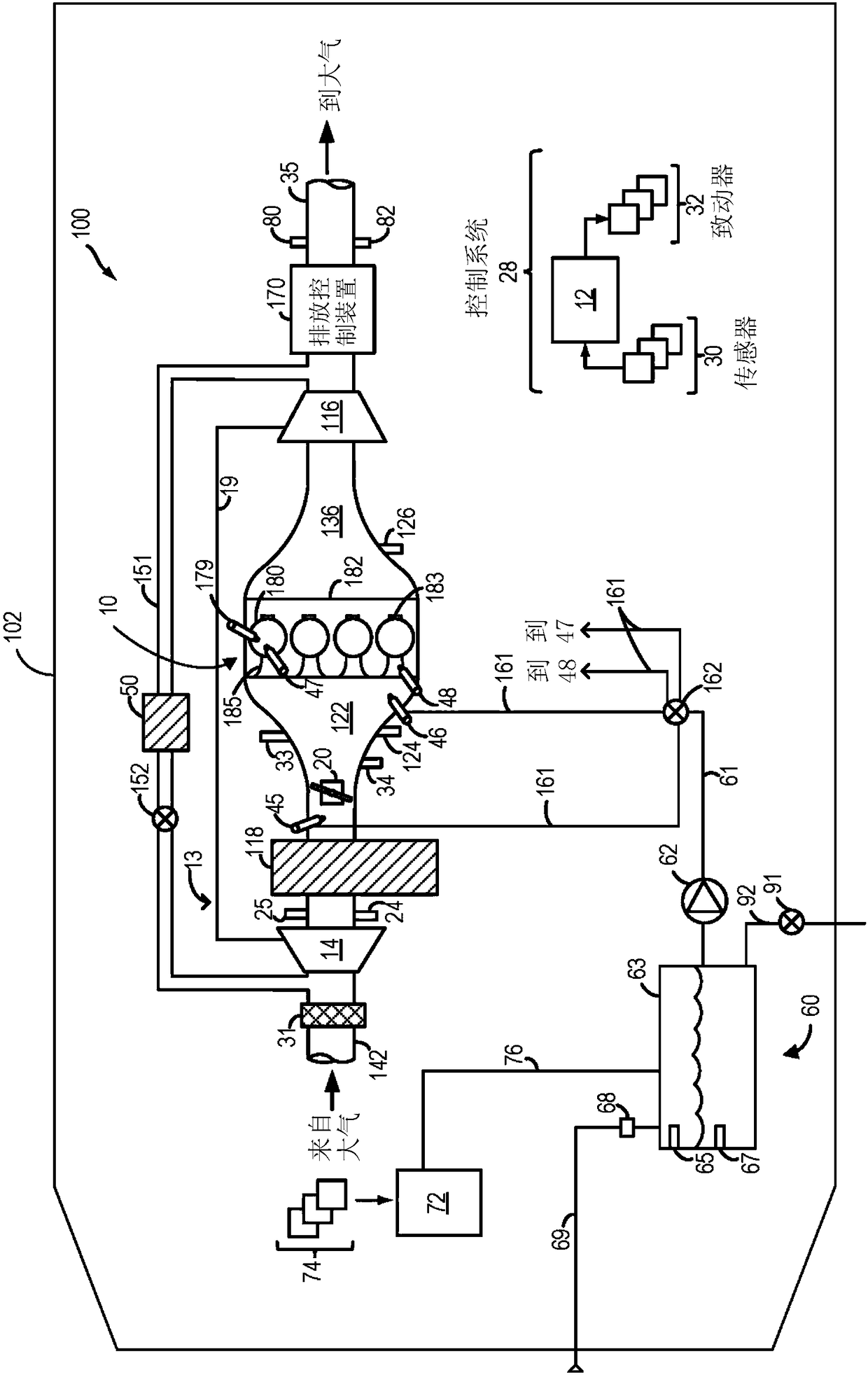

[0014] The following description relates to systems and methods for improving the use of water from a water injection system coupled to a vehicle engine, as referenced figure 1 The vehicle system described. as reference Figure 2 to Figure 4 As shown, the engine system may be configured with water injectors at various locations to provide various water injection benefits such as charge air cooling, engine component cooling, and engine dilution. The controller can be configured to execute control programs such as Figure 5 A sample program to learn and compensate for imbalanced water distribution between cylinders due to differences in air flow, pressure, and architecture for each cylinder. The controller may learn the delivery delay for each cylinder via the intake oxygen sensor based on the amount and timing of the dilution after the pulsed manifold water injection. Therefore, the amount and timing of water injection relative to cylinder intake valve timing can be adjusted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com