Mobile pneumatic type grain pile accumulated heat discharge mechanism

A pneumatic, heat-dissipating mechanism technology, used in climate change adaptation, agricultural machinery and implements, fruit suspension devices, etc., can solve problems such as grain damage, reduce workload, strengthen distribution, and ensure the quality of grain storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

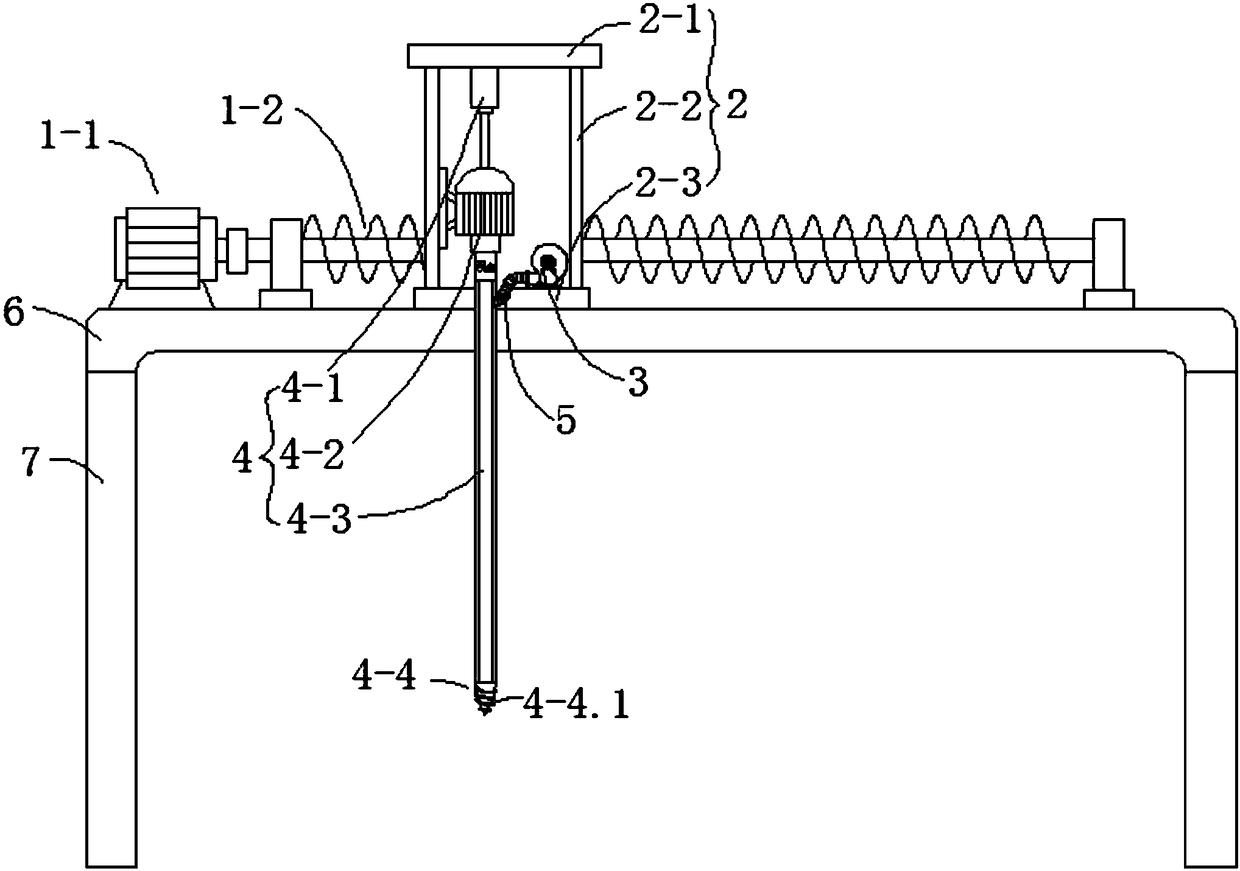

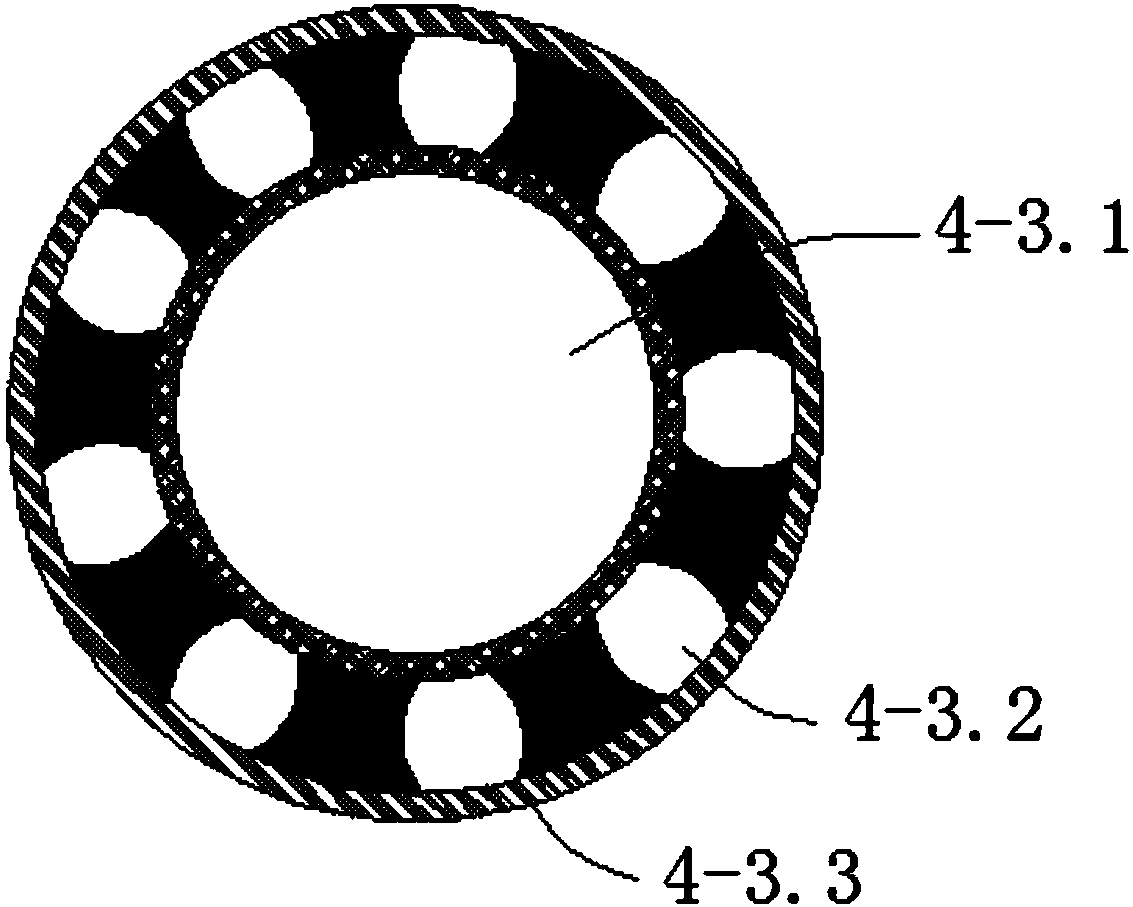

[0020] Such as Figure 1 to Figure 3 As shown, this embodiment provides a mobile pneumatic grain pile heat removal mechanism, including two symmetrically arranged support plates 7 and a mounting plate 6 horizontally erected on the top of the two support plates 7, and the mounting plate 6 is provided with a horizontal movement mechanism 1. The horizontal moving mechanism 1 is connected with a moving seat 2, and the moving seat 2 is provided with a lifting and cooling mechanism 4 and a blower 3 connected with the lifting and cooling mechanism 4. The lifting and cooling mechanism 4 includes a forward and reverse motor 4-2, which drives the The lifting cylinder 4-1 that the motor 4-2 moves up and down and the ventilation rod 4-3 connected to the output shaft of the forward and reverse motor 4-2, the mounting plate 6 is dug with a through groove 6 for the horizontal movement of the ventilation rod 4-3 -1, the interior of the ventilation rod 4-3 is vertically provided with a ventila...

Embodiment 2

[0023] This embodiment is further optimized on the basis of Embodiment 1, specifically:

[0024] The outer wall of the ventilation rod 4-3 is provided with a breathable film layer 4-3.3 for preventing grain from entering the ventilation rod 4-3 from the ventilation hole 4-3.2, so as to prevent the grain from entering the ventilation rod 4-3 and affecting the normal operation of the equipment , to ensure the efficiency of the cooling work.

Embodiment 3

[0026] This embodiment is further optimized on the basis of Embodiment 2, specifically:

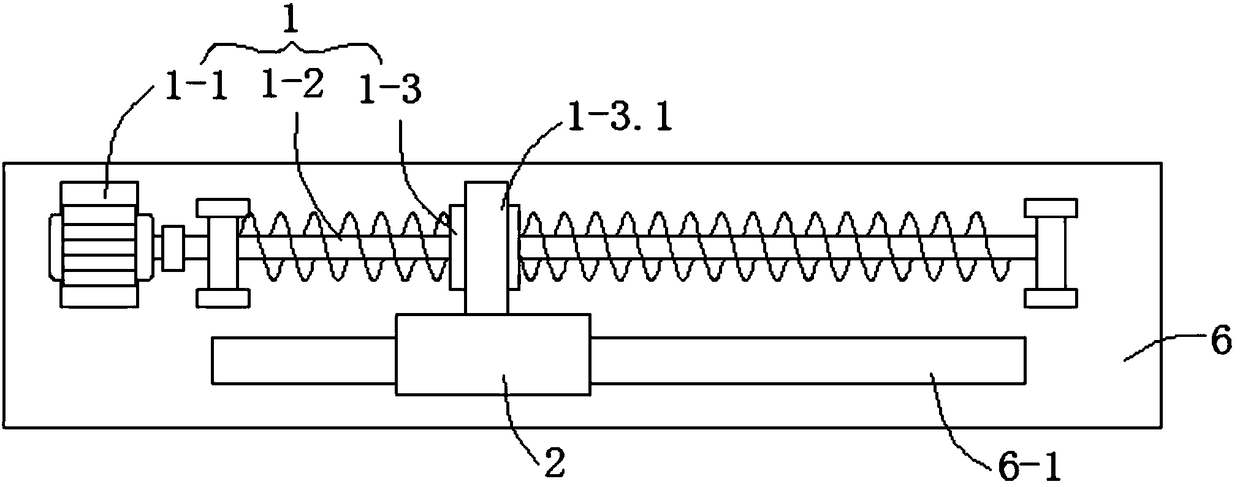

[0027] The horizontal movement mechanism 1 includes a drive motor 1-1, a ball screw 1-2 fixedly connected to the output shaft of the drive motor 1-1, and a ball set on the ball screw 1-2 to match the ball screw 1-2. The nut 1-3 and the ball nut 1-3 are provided with a connecting block 1-3.1 fixedly connected with the moving seat 2.

[0028] The moving seat 2 includes a moving bottom plate 2-3 slidingly fitted with the mounting plate 6, two vertical plates 2-2 symmetrically arranged on the moving bottom plate 2-3, and a horizontal plate 2-2 erected on the top of the two vertical plates 2-2. 1. The forward and reverse motor 4-2 is vertically installed on one of the vertical plates 2-2, the lifting cylinder 4-1 is placed upside down on the horizontal plate 2-1, and the piston rod of the lifting cylinder 4-1 is connected with the positive and negative motor 4 -2 is fixedly connected, and a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com