Residual film removal device and residual film removal system

A technology for removing devices and residual films, which is applied in the direction of grinding/polishing safety devices, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, low production efficiency, and long processing time, so as to reduce labor intensity, The effect of improving productivity and reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

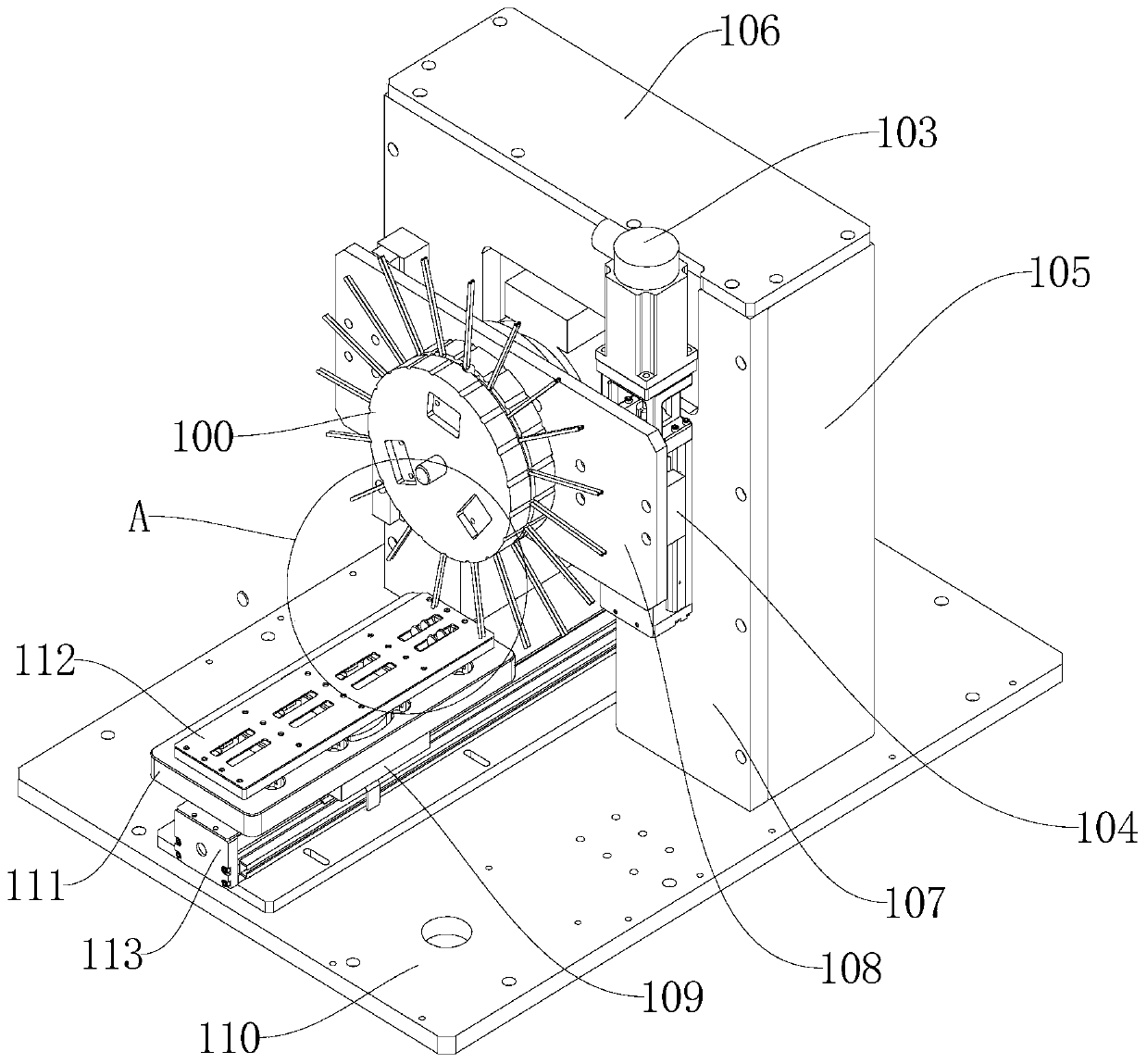

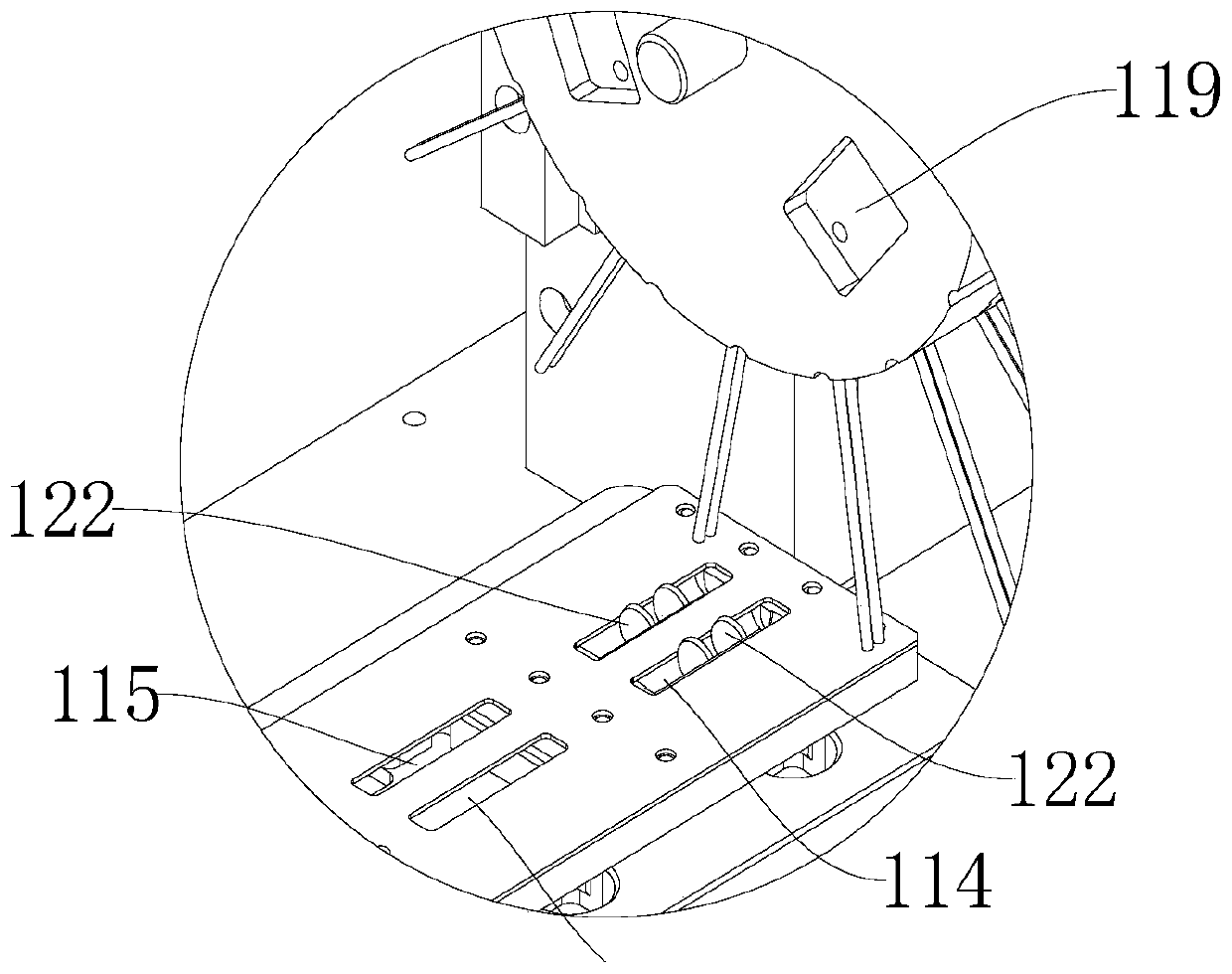

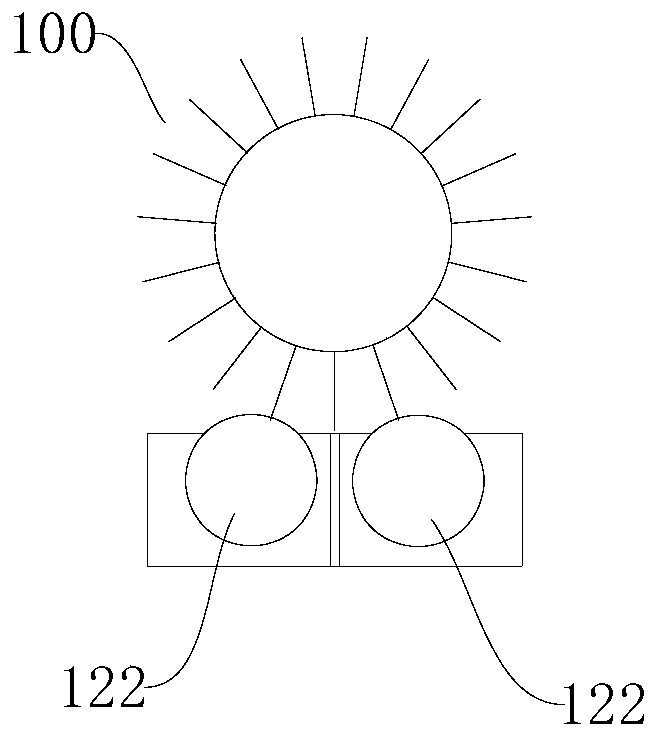

[0037] see Figure 1 to Figure 7 As shown, Embodiment 1 of the present invention provides a residual film removal device, including a polishing wheel 100, a power device, a lifting mechanism and a sliding mechanism; the power device is installed on the lifting mechanism, and the lifting mechanism can drive the polishing wheel 100 along the The lifting direction of the lifting mechanism moves, that is to say, the lifting mechanism drives the power unit and the polishing wheel 100 to move together along the lifting direction of the lifting mechanism; the sliding mechanism is used to drive the sheet product 122 to be removed to move along the sliding direction of the sliding mechanism; polishing The wheel disc 100 includes a disc body 101 and a plurality of glass fiber sleeves 102, and the plurality of glass fiber sleeves 102 are arranged at intervals in the circumferential direction of the disc body 101; the power device is used to drive the polishing wheel 100 to rotate, and thr...

Embodiment 2

[0053] see Figure 8 and Figure 9 As shown, Embodiment 2 of the present invention provides a system for removing residual film, including a system bracket and the device for removing residual film provided in Embodiment 1. The device for removing residual film is installed on the system bracket 127 . A control box 124 and a protective cover 125 are also installed on the system bracket; the control box is electrically connected to the first motor, the second motor 103 and the third motor respectively. The protective cover is used to prevent the glass fiber sleeve 102 on the polishing wheel 100 from being thrown off during the rotation of the polishing wheel 100 . Specifically, the installation base plate 110 is fixed on the system bracket; the control box is fixed on the installation base plate 110; a baffle plate 126 is installed on the protective cover, and the baffle plate can move up and down along the length direction of the slot on the protective cover. The baffle can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com