Self-propelled type rope sawing machine

A wire saw machine and self-propelled technology, applied in the field of rock engineering machinery, can solve problems such as rope clamping in the rope groove, slippage, mismatch between the rope groove of the main drive wheel and the saw rope, etc., to achieve rapid movement and installation, enhanced applicability, The effect of enhancing operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

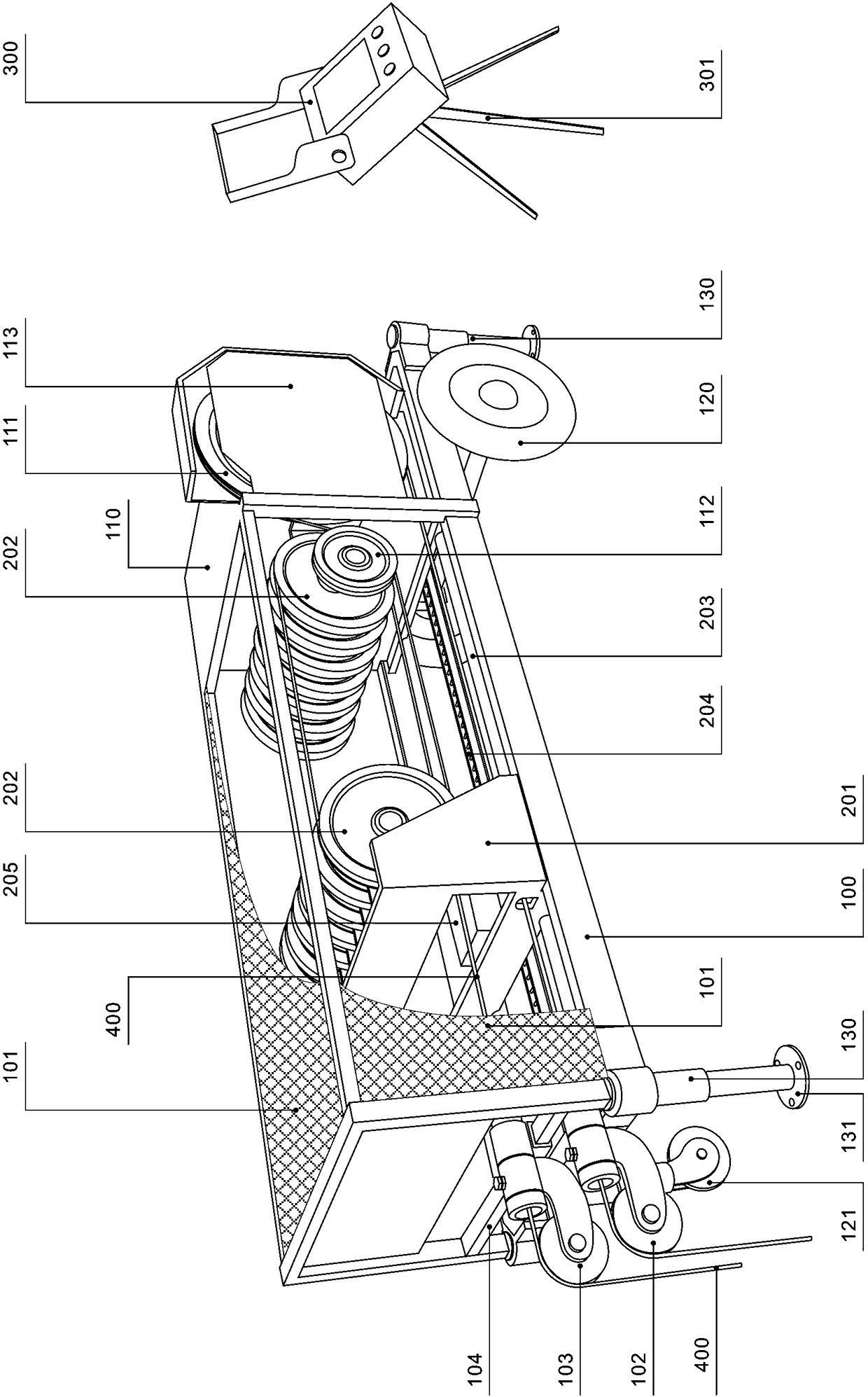

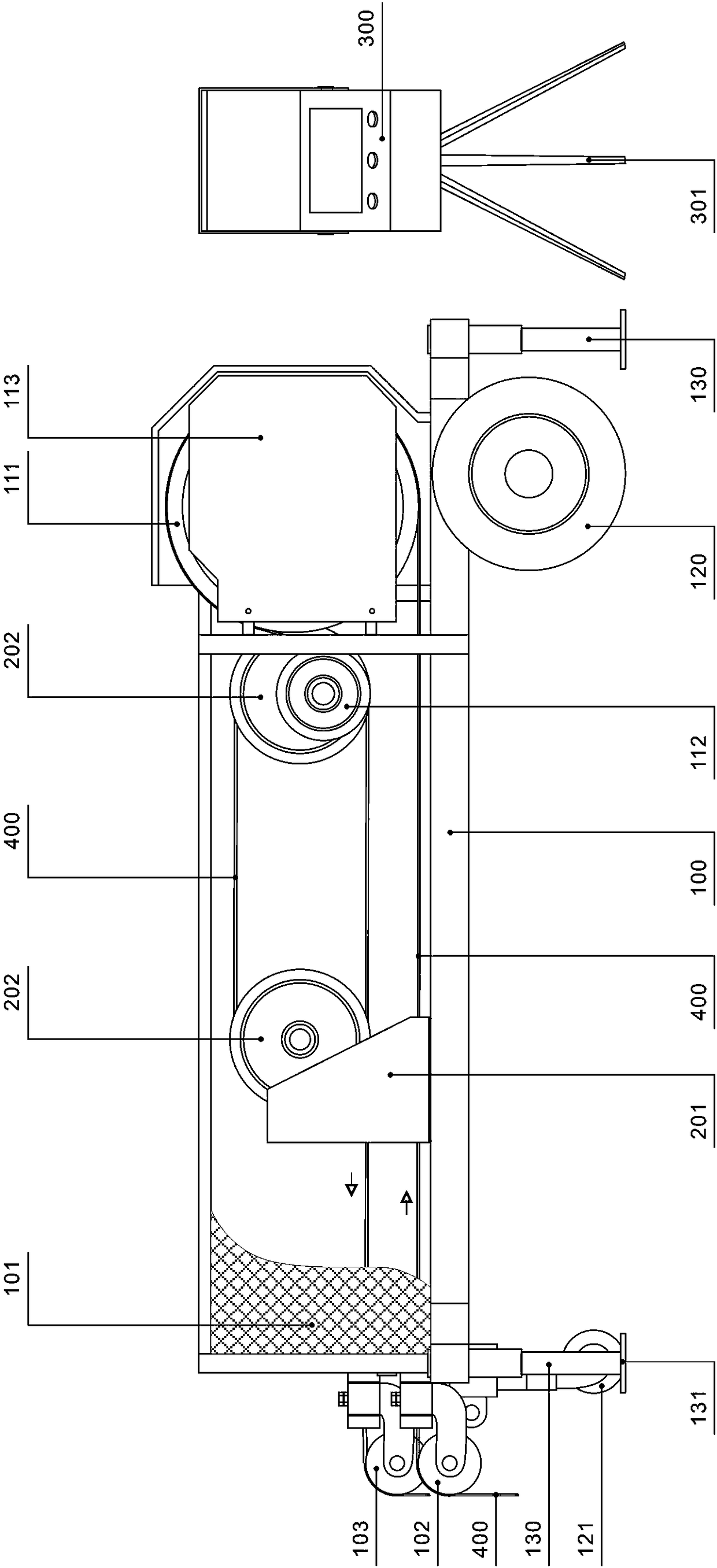

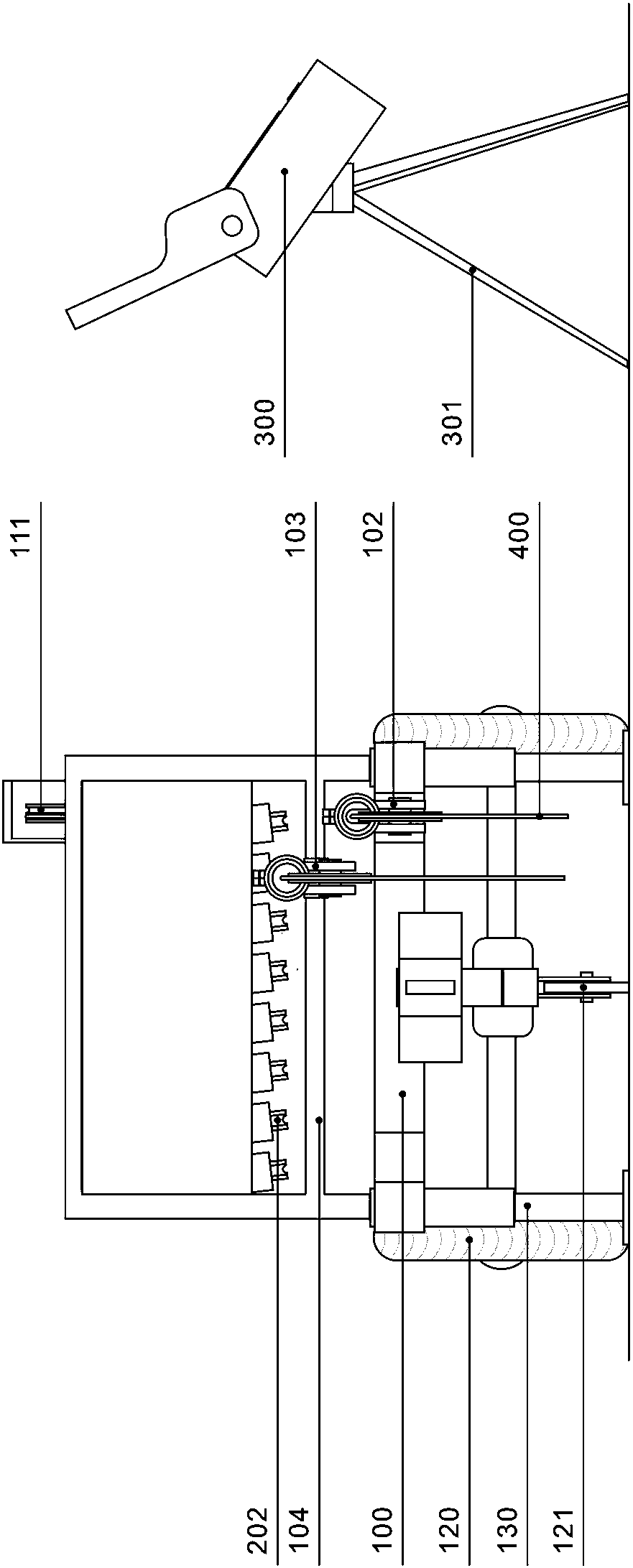

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings. according to figure 1 , figure 2 , image 3 As shown, the present invention is made up of the following parts: main frame (100), main frame (110), rope storage system, universal guide wheel mechanism, frame walking system, frame supporting device, control system, movable protective cover (101 ). The frame walking system is a wheel structure or a crawler structure, and the wheel structure is given in this embodiment. The rack walking system includes a driving wheel part (120) and a steering wheel part (121). The drive wheel part includes: a drive wheel motor, a differential, and a drive wheel. The steering wheel part includes a steering motor and a universal wheel. The frame support device includes a plurality of telescopic support rods. Each telescopic support rod comprises: a telescopic rod (130), a telescopic rod driving motor and a foot plate (131). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com