Anti-winding structure during leather cleaning treatment

A kind of leather and anti-rolling technology, which is applied in the fields of small raw hide/big raw hide/leather/fur treatment, leather/skin/leather/raw hide chemical treatment equipment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., to improve The effect of exercise state, reduction of reaction time, and dosage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

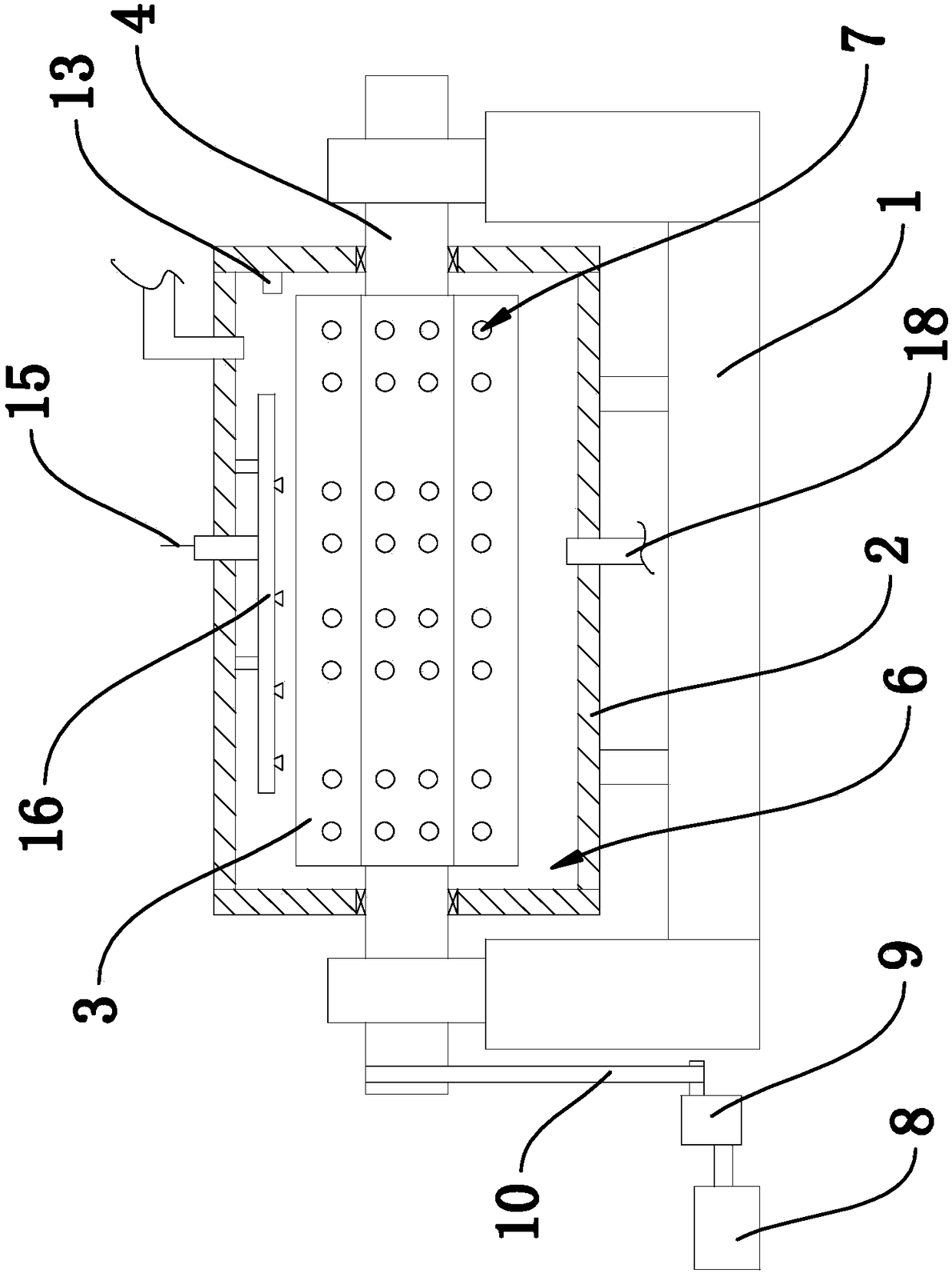

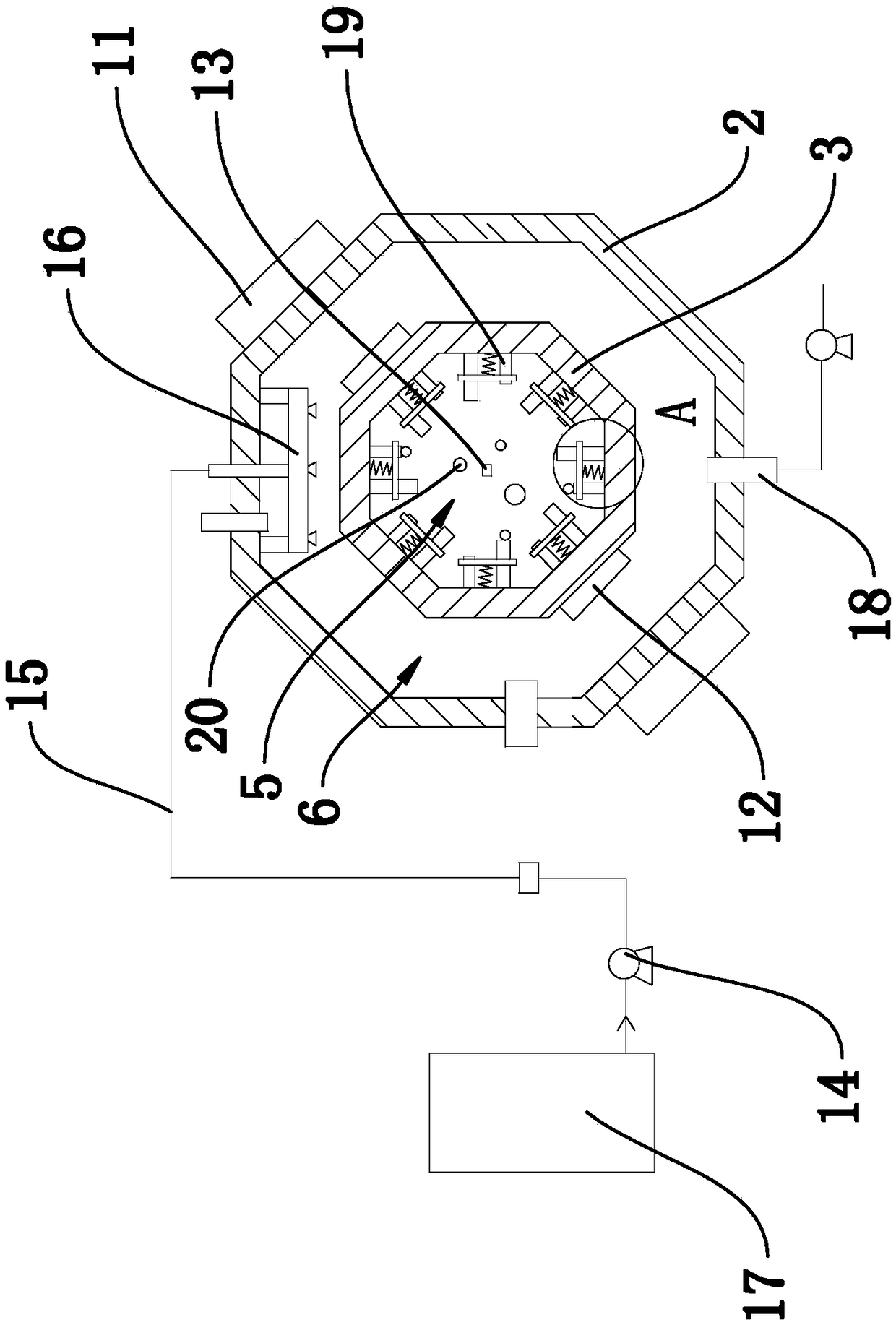

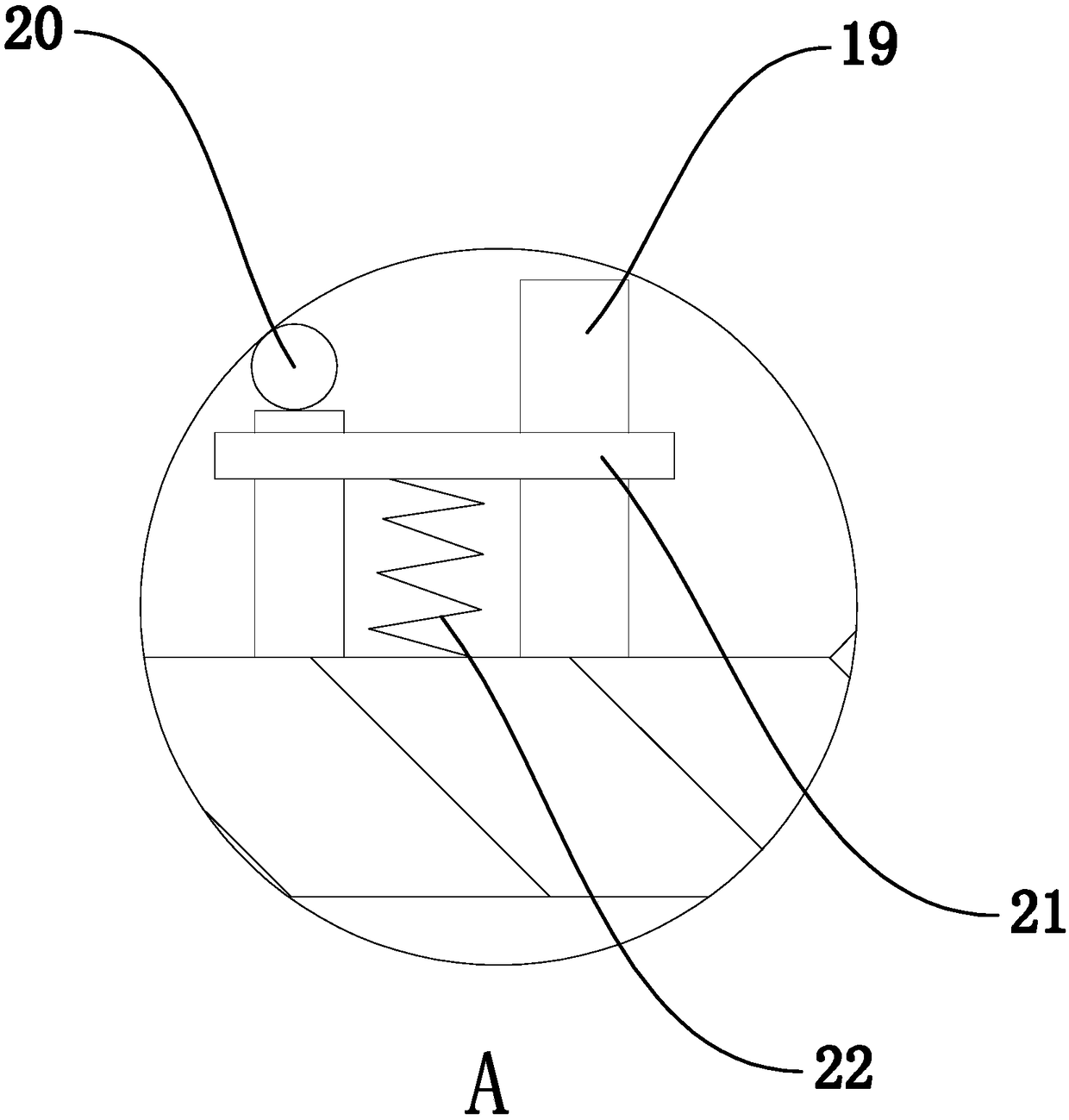

[0030] like Figure 1 to Figure 7 As shown, the present invention provides a leather drum device for cleaning leather, including a drum body, a base 1 and a drive mechanism, the drum body is installed on the base 1, the drive mechanism is connected to the drum body, and the drum body is connected to the drum body. The drum body includes an outer drum body 2 and an inner drum body 3. The two ends of the inner drum body 3 have a rotating shaft 4. The inner drum body 3 is rotatably installed in the outer drum body 2. The inner drum body 3 has an inner drum cavity for accommodating leather. 5. An outer tympanic cavity 6 is formed between the outer drum body 2 and the inner drum body 3, and the inner drum body 3 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com