Method for increasing yield of IF steel alloy

A technology of yield and steel alloy, which is applied in the field of improving the yield of IF steel alloy, can solve the problems of low alloy yield and achieve the effect of improving alloy yield and alloy yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

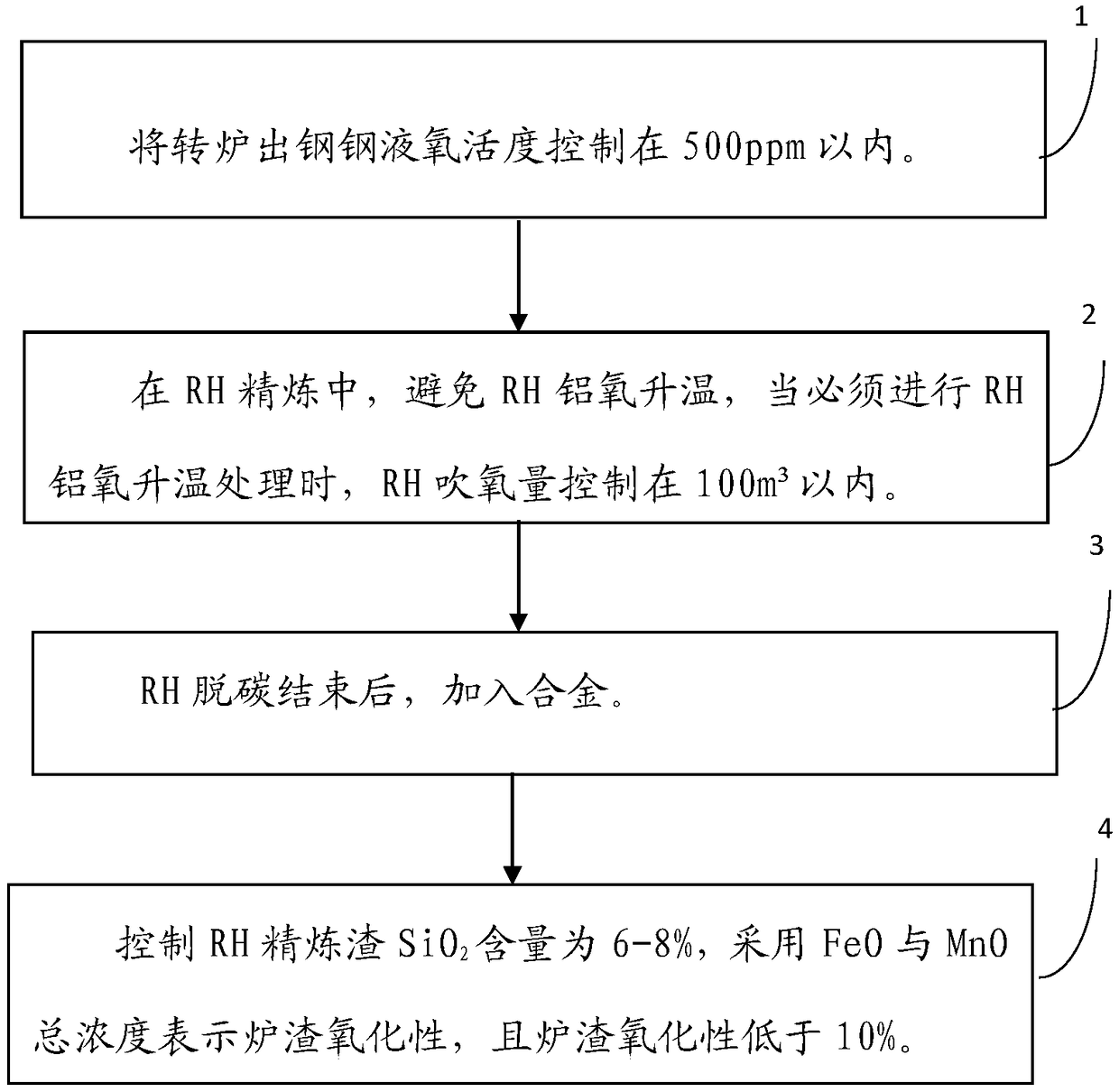

[0023] figure 1 It is a schematic flowchart of a method for improving the uniformity of the uncoiling oil film of a cold-rolled galvanized sheet in an embodiment of the present invention. Such as figure 1 As shown, the method includes:

[0024] Step 1: Control the oxygen activity of the converter tapping molten steel within 500ppm.

[0025] Further, in the step 1, the incoming oxygen activity is reduced, and the decarburization conditions need to be guaranteed.

[0026] Specifically, the IF steel is the abbreviation of Interstitial Free Steel, that is, interstitial-free steel, sometimes also called ultra-low carbon steel, which has excellent deep drawing performance and has been widely used in the automobile industry. In IF steel, due to the low content of C and N, a certain amount of titanium, niobium and other strong carbon-nitrogen compound forming elements are added to completely fix the carbon, nitrogen and other interstitial atoms in ultra-low carbon steel into carbon...

Embodiment 2

[0041] A kind of method of improving IF steel alloy yield of the present invention is described in detail below, specifically as follows:

[0042] In an embodiment of the present invention, a method for increasing the yield of IF steel alloy is provided. Firstly, in the process of controlling the end point of the converter, the oxygen at the end point of the converter smelting is controlled within 500ppm, the slag is used to tap the steel, and the target slag thickness at the refining station is ≤130mm; secondly, during the RH refining process, the RH entering station temperature is controlled at 1640°C; Oxygen blowing is carried out within 4 minutes of the start of vacuuming, and the oxygen blowing volume is 80m 3 ; The refining period is 45min, and the pure cycle time is 6min; control the basicity R and oxidation of the slag in the RH refining process, that is, control the refining slag SiO 2 The CaO content in the slag is C / A=1.7 with a content of 7% and a slag oxidizing p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com