Outside-sealed displacement adjusting mechanism for parallel-connection spray pipe

A technology of external sealing and displacement adjustment, applied in the direction of machine/engine, jet propulsion device, etc., can solve the problem that scramjet cannot be completed independently, achieve good thrust performance, maintain air tightness, and improve the effect of outlet airflow state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

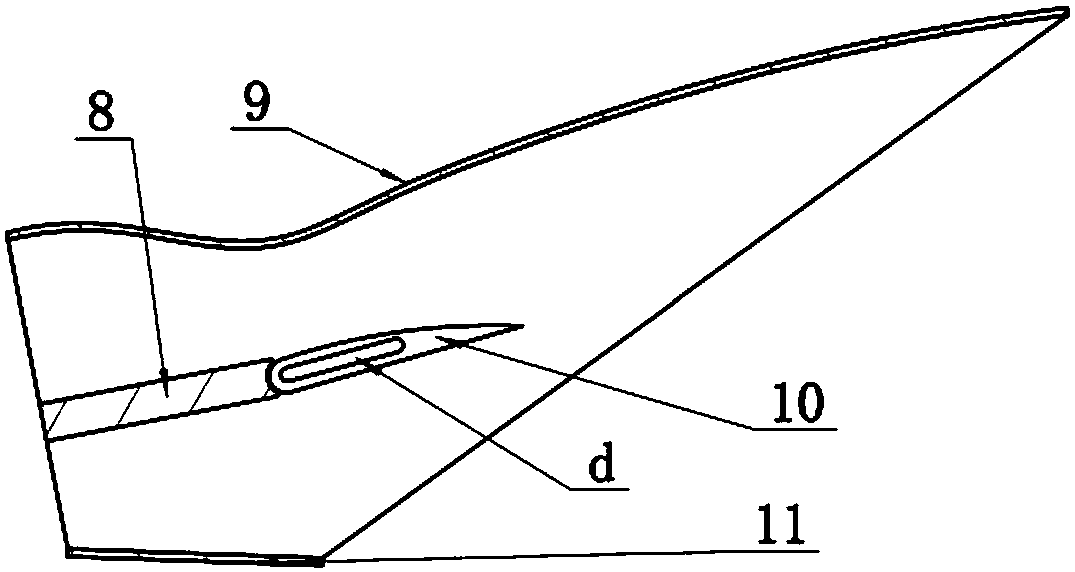

[0018] The invention proposes a displacement adjustment mechanism for externally sealed parallel nozzles, which can realize the purpose of adjusting the rotation of the diverter plate without affecting the internal flow of the nozzles.

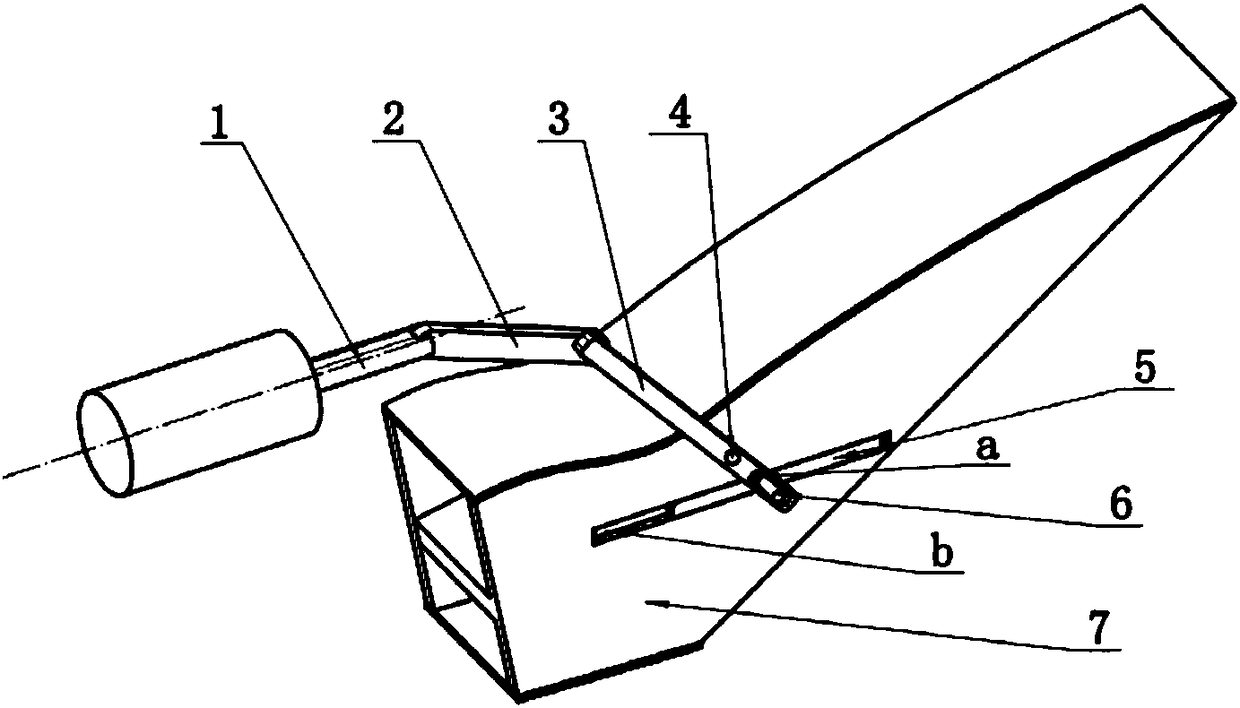

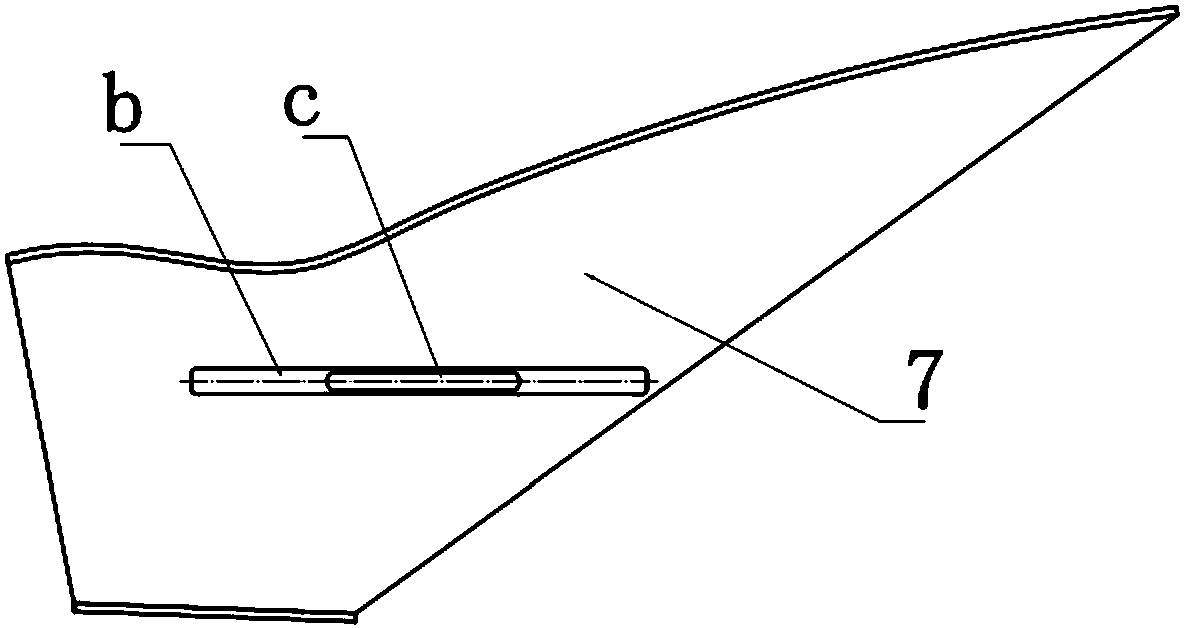

[0019] figure 1 Shown is the isometric side view of the parallel nozzle and the adjustment mechanism, including two passages, the upper passage is the turbine passage, and the lower passage is the stamping passage, and the adjustment mechanism proposed by the present invention is located outside the nozzle. figure 2 It is a schematic diagram of the installation structure of the side plate of the mechanism at the position where the mechanism is perforated and grooved on the wall of the nozzle.

[0020] The combined engine parallel nozzle has multiple working states throughout the voyage, and the nozzle needs to adjust the splitter plate according to different working states to reduce the energy loss of under-expansion or over-expansion of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com