Electric pump control method and system

A control method and control system technology, applied in the field of electric pumps, can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

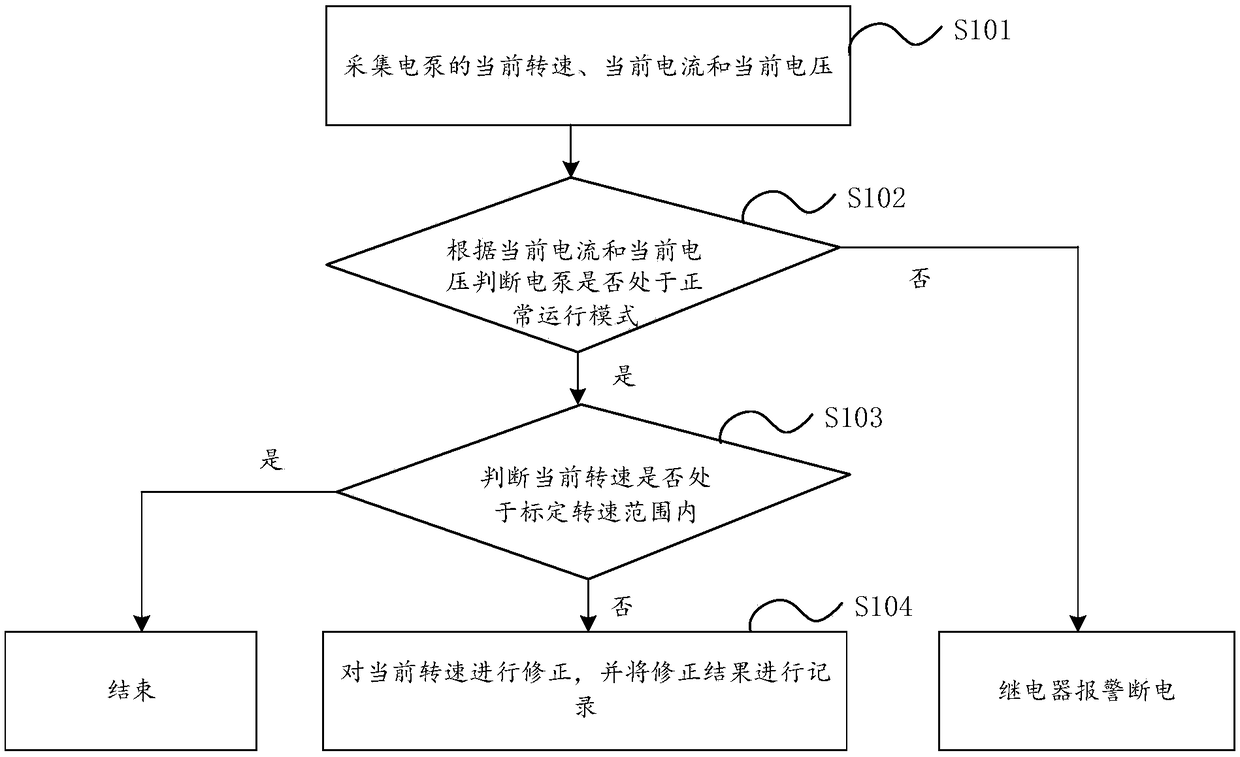

[0049] figure 1 It is a flow chart of the electric pump control method provided by the embodiment of the present invention.

[0050] refer to figure 1 , the electric pump control method includes:

[0051] Step S101, collecting the current rotational speed, current current and current voltage of the electric pump;

[0052] Specifically, the electric pump is provided with an electric pump controller, a rotational speed acquisition device and a current acquisition device, wherein the rotational speed acquisition device and the current acquisition device are respectively connected to the electric pump controller.

[0053] The speed acquisition device is used to collect the speed information of the electric pump, and transmit the speed information to the connected electric pump controller in real time. Here, the rotational speed collection device includes a rotational speed sensor, and the current collection device includes one of a current sensor, an ammeter, a multimeter, or a...

Embodiment 2

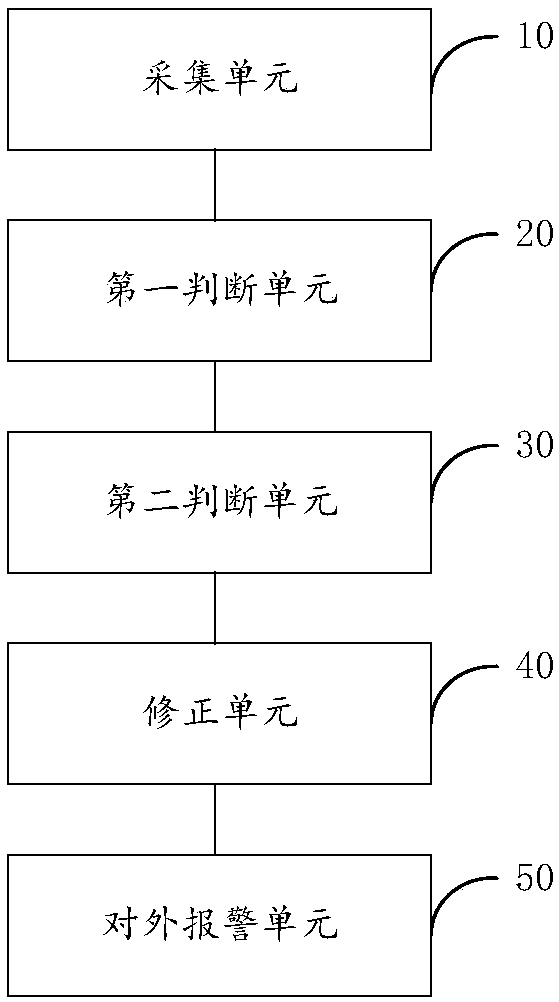

[0085] figure 2 It is a schematic diagram of the electric pump control system provided by the embodiment of the present invention.

[0086] refer to figure 2 , the electric pump control system includes:

[0087] The acquisition unit 10 is used to acquire the current rotational speed, current current and current voltage of the electric pump;

[0088] The first judging unit 20 is used to judge whether the electric pump is in a normal operation mode according to the current current and the current voltage;

[0089] The second judging unit 30 is configured to judge whether the current rotational speed is within the calibrated rotational speed range in the case of the normal operation mode;

[0090] The correction unit 40 is configured to correct the current rotational speed when the rotational speed is not within the calibrated rotational speed range, and record the correction result.

[0091] According to an exemplary embodiment of the present invention, it also includes: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com