Two-grade pressure reducing disc and pressure reducing valve

A pressure reducing valve and body technology, applied in valve details, safety valves, balance valves, etc., can solve the problems of many parts, complex structure, and many parts used, and achieve fast speed, simple structure, and obvious pressure reduction effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

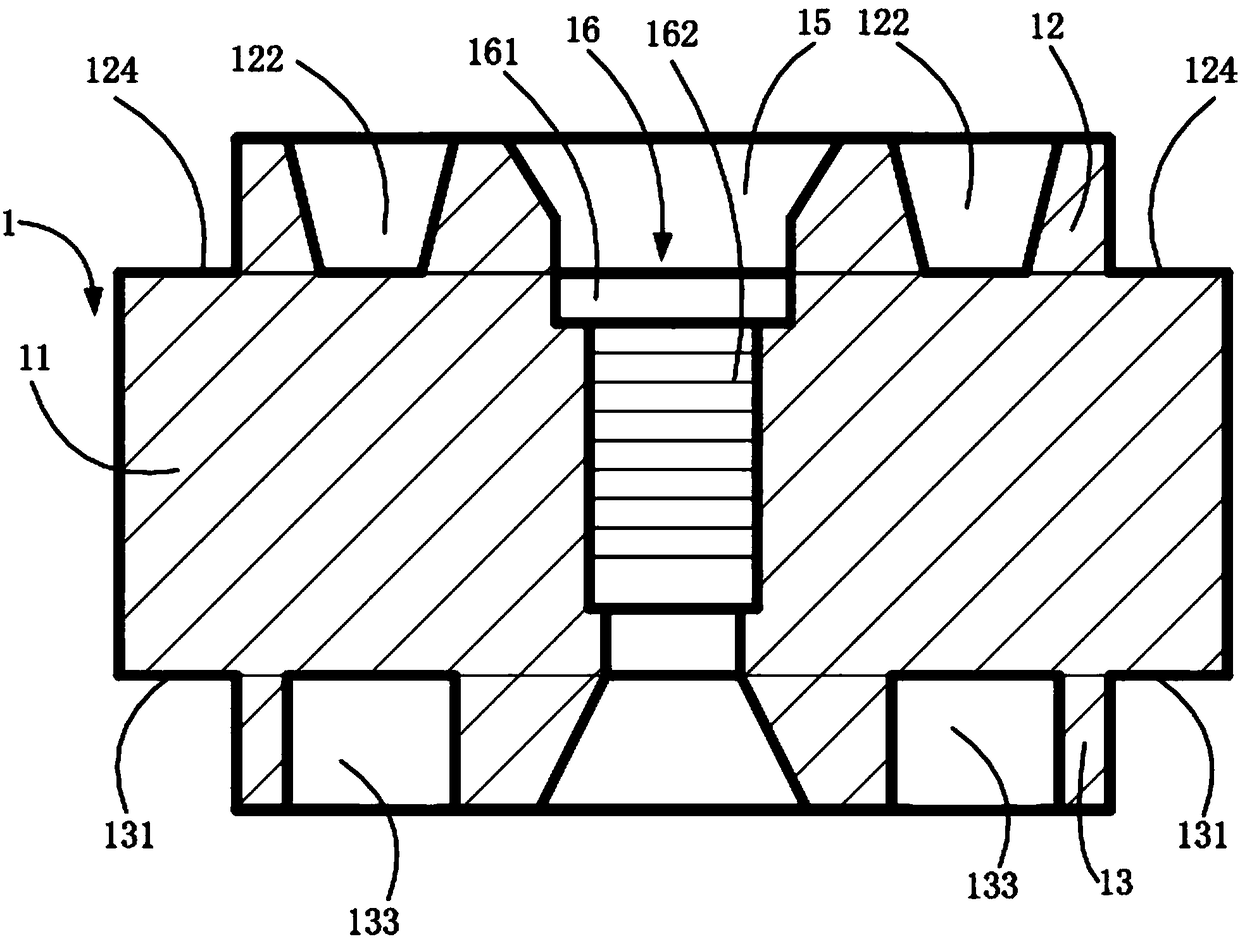

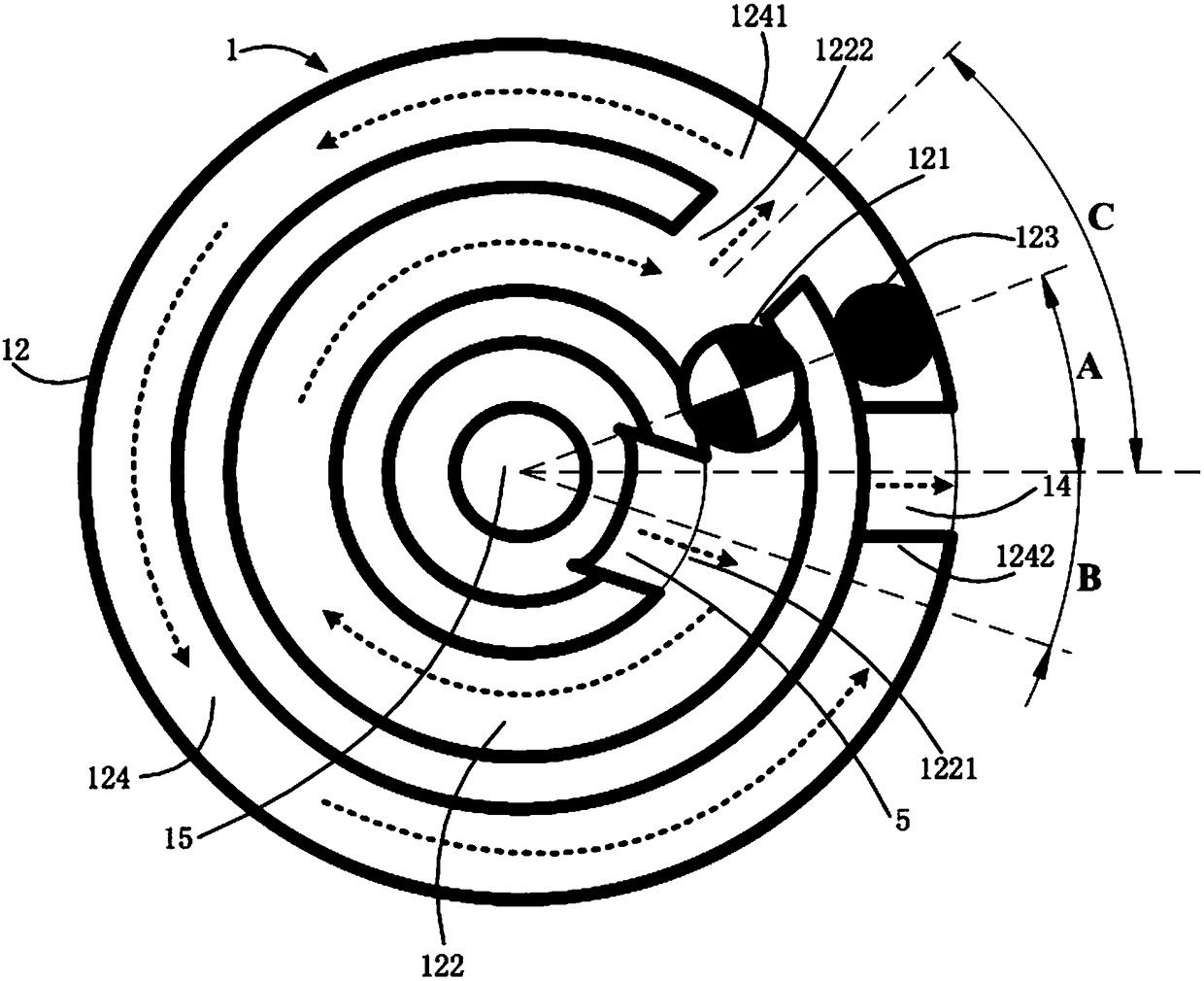

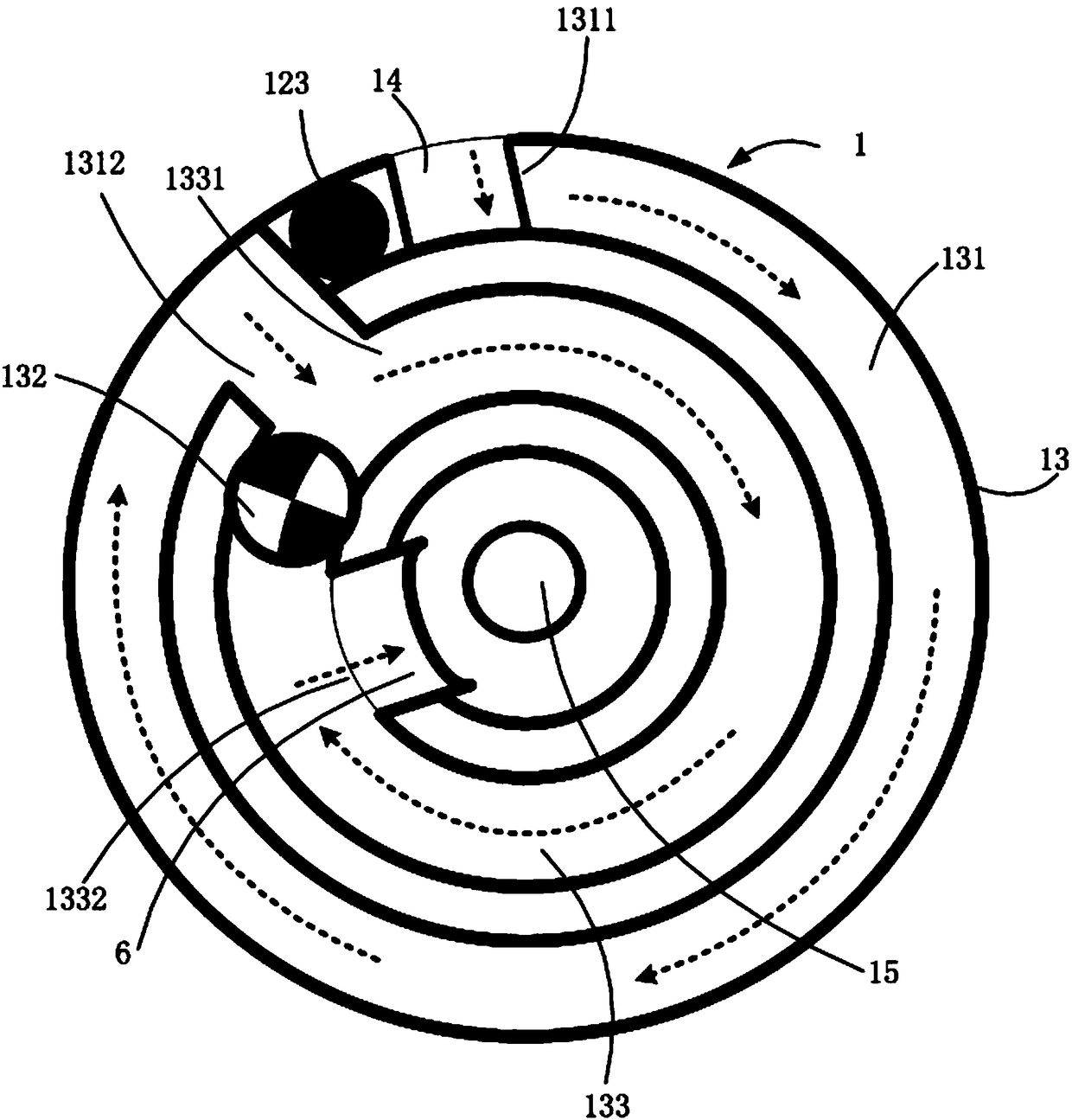

[0077] Please refer to figure 1 , is a cross-sectional view of the secondary decompression disk 1 in this embodiment. This embodiment provides a two-stage decompression disk 1 , which includes: a disk body 11 , a first rotating structure 12 , a second rotating structure 13 and an airflow groove 14 . Wherein, the disk body 11 is approximately cylindrical, which has an upper bottom surface, a peripheral side surface and a lower bottom surface; when the first rotating structure 12 moves the high-pressure gas along it, it forms a continuous rotating airflow direction with two different rotating diameters, which Centered on the center of the upper bottom surface of the disk body 11, the ring is set on the upper bottom surface of the disk body 11; the second rotating structure 13 also makes the high-pressure gas move along it, forming a continuous rotating airflow direction with two different rotating diameters, which is represented by The center of the bottom surface of the disk b...

Embodiment 2

[0082] Please refer to Figure 4 , is a cross-sectional view of the secondary pressure reducing valve in this embodiment. This embodiment provides a secondary pressure reducing valve, which includes: a shell barrel 2 , an air inlet cover 3 , an air outlet cover 4 and a secondary pressure reducing plate 1 . The air intake cover 3 is located on the top of the shell barrel 2, and an air intake 31 is provided on it, such as Figure 5 , the air intake cover 3 includes a first cover 32 and a second cover 33, the diameter of the first cover 32 is smaller than the diameter of the second cover 33, the first cover 32 is partially embedded in the second cover 33, the first The central axes of the cover body 32 and the second cover body 33 coincide, and the air inlet 31 extends from the first cover body 32 to the second cover body 33; the air outlet cover 4 is arranged at the bottom of the shell barrel 2, and an air outlet port is arranged on it 41 ; the secondary decompression plate 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com