Energy-saving hot air drying system and energy-saving hot air drying method

A technology of hot air drying and drying box, which is applied in the direction of drying gas arrangement, drying, drying machine, etc., to achieve the effect of easy removal, increase concentration, and reduce ineffective exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

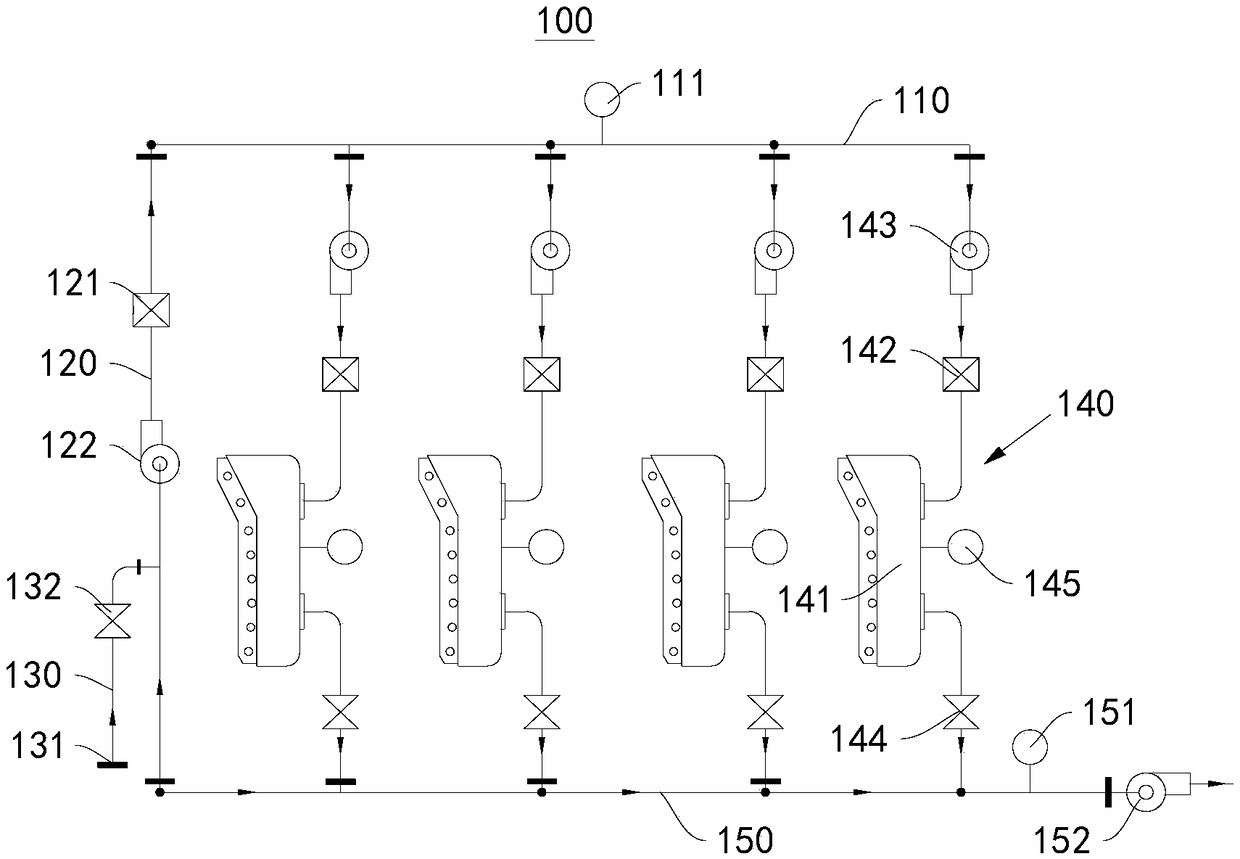

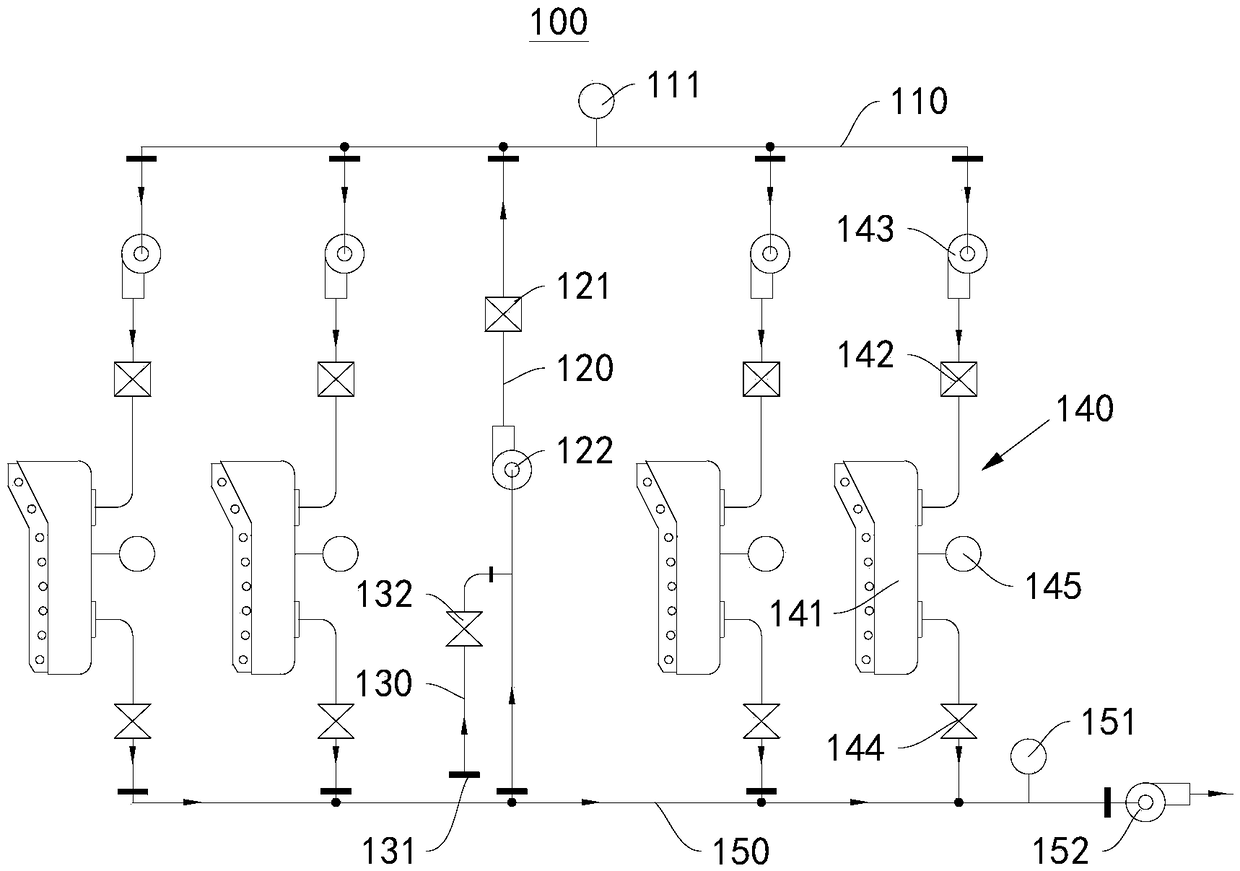

[0053] This embodiment provides an energy-saving hot air drying system 100, please refer to figure 1 , figure 2 , image 3 as well as Figure 4 , this energy-saving hot air drying system 100 includes:

[0054] Air supply duct 110;

[0055] Exhaust duct 150, exhaust duct 150 is connected with exhaust fan 152, exhaust fan 152 is used to discharge the gas in the exhaust duct 150 to the external environment;

[0056] A communication duct 120, one end of the communication duct 120 communicates with the air supply duct 110, and the other end communicates with the exhaust duct 150;

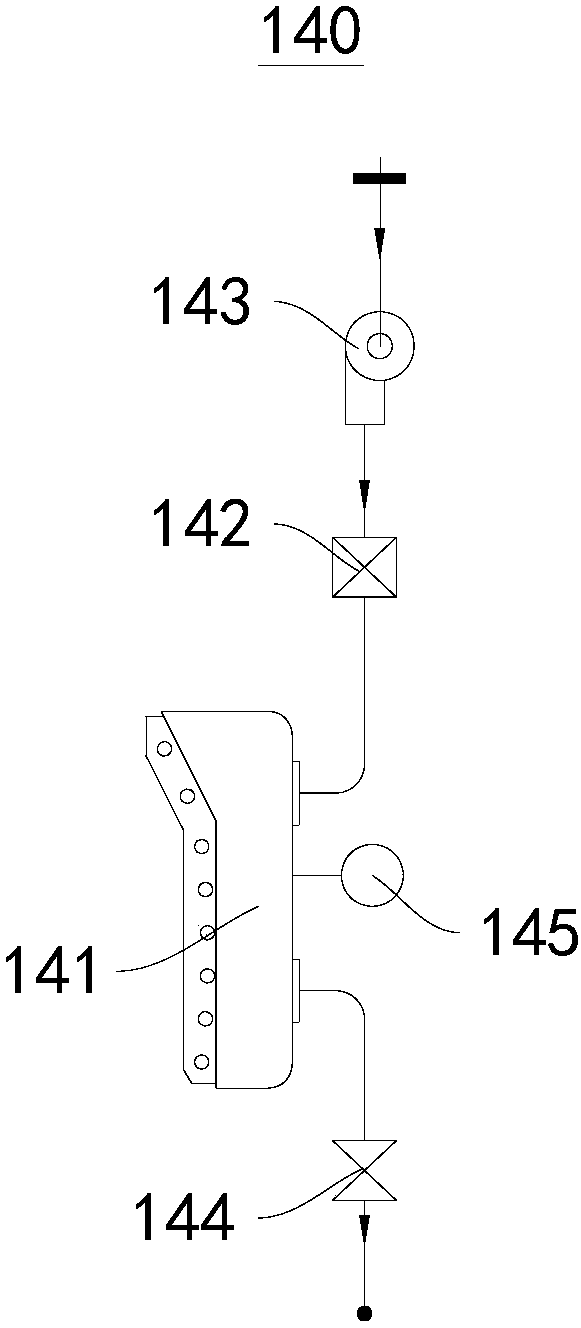

[0057] A plurality of drying units 140, one end of the plurality of drying units 140 is in communication with the air supply duct 110, and the other end is in communication with the exhaust duct 150;

[0058] The drying unit 140 includes: a drying box 141 and a blower fan 143, the blower fan 143 is connected to the drying box 141, and the blower fan 143 is used to discharge the gas in the air suppl...

Embodiment 2

[0095] This embodiment provides an energy-saving hot air drying method, which includes the following steps:

[0096] According to the feedback value of the first pressure sensor 111 , the frequency of the booster fan 122 is adjusted so that the inside of the air supply duct 110 is in a slightly negative pressure state.

[0097] Adjust the opening of exhaust valve 144 to the maximum, gradually increase the frequency of exhaust fan 152, until all are in the negative pressure state in the drying box 141, read the pressure value of the feedback of the second pressure sensor 151 at this time, adjust The frequency of the exhaust fan 152 makes the pressure in the exhaust duct 150 approach to this pressure value all the time.

[0098] Adjust the opening of the exhaust valve 144 one by one, so that the air pressure inside each drying box 141 is in a slightly negative pressure state.

[0099] Wherein, the slightly negative pressure state is that the relative pressure is between -100Pa~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com