A water chamber arrangement method and arrangement structure of a water-cooled condenser

A condenser and water condensation technology, applied in steam/steam condensers, heat exchanger shells, lighting and heating equipment, etc., can solve the problems affecting the stability and reliability of water-cooled condensers and the manufacturing cost of water-cooled condensers increase, weak compressive capacity, etc., to achieve the effect of simple structure, compact structure volume and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

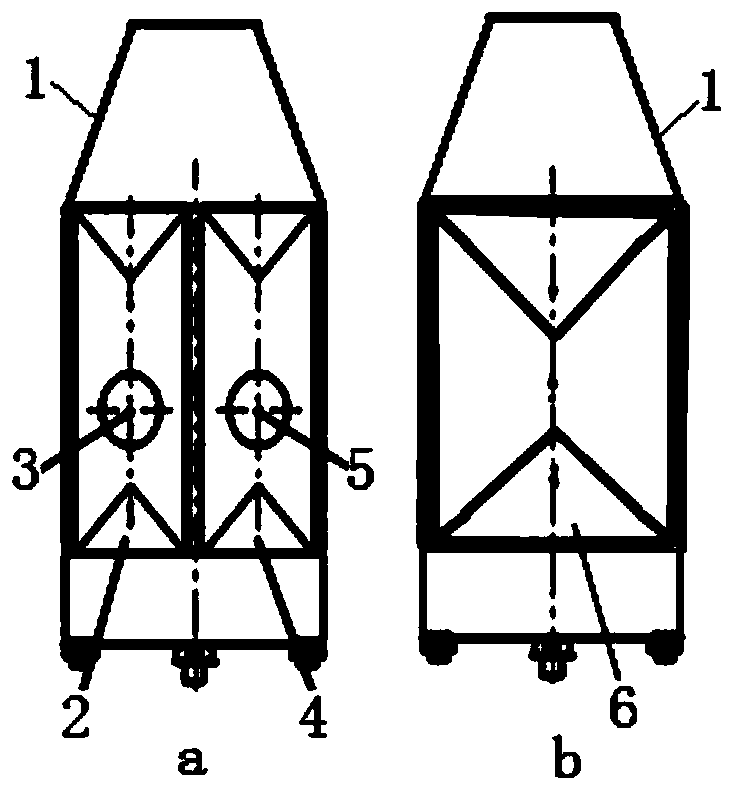

[0024] The present invention is a method for arranging water chambers of a water-cooling condenser with a double-flow structure in the left and right directions. A fluid return bending area between the water chamber and the outlet water chamber process. The function of the fluid return bending area is to turn the water flow from the inlet water chamber through the heat exchange chamber in the left and right directions and guide it to enter the outlet water chamber through the heat exchange chamber. . In the present invention, the fluid return bending area at the rear side of the water-cooling condenser is divided into two space-independent return areas along the direction of the return bending of the fluid, that is, the left and right directions, in a manner of diverting and controlling the return bending fluid (ie, water flow). For water bend chambers, it is best to follow the principle of equal division for the division of multiple bend water chambers in the same fluid retur...

Embodiment 2

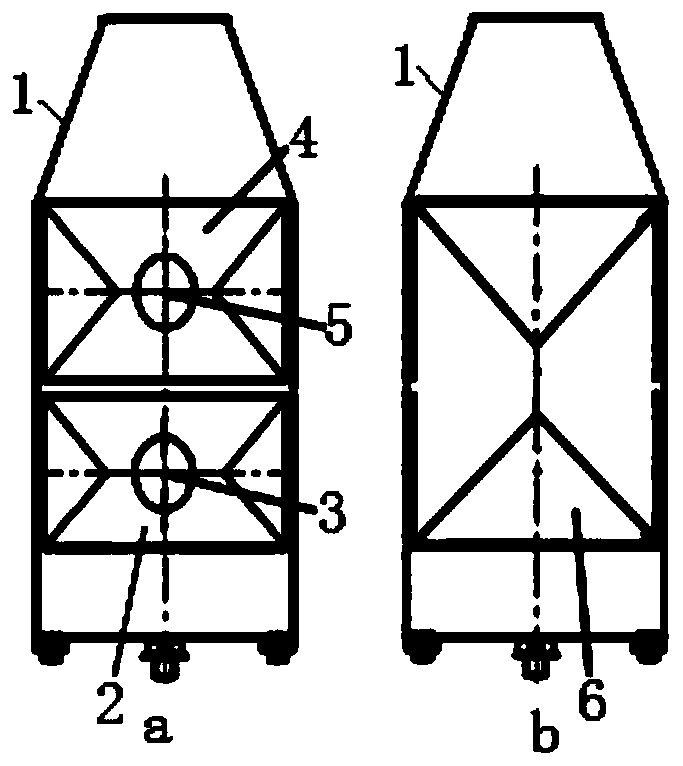

[0027] The present invention is a method for arranging water chambers of a water-cooling condenser with a double-flow structure in the up-and-down direction. A fluid return bending area between the water chamber and the outlet water chamber process, the function of the fluid return bending area is to turn the water flow from the inlet water chamber through the heat exchange chamber in the up and down direction and guide it to enter the outlet water chamber through the heat exchange chamber . In the present invention, the fluid return bending area at the rear side of the water-cooling condenser is divided into two space-independent return areas along the direction of the return bending of the fluid, i.e., the up and down direction, in a way of diverting and controlling the return bending fluid (ie, water flow). For water bend chambers, it is best to follow the principle of equal division for the division of multiple bend water chambers in the same fluid return bend area, so as ...

Embodiment 3

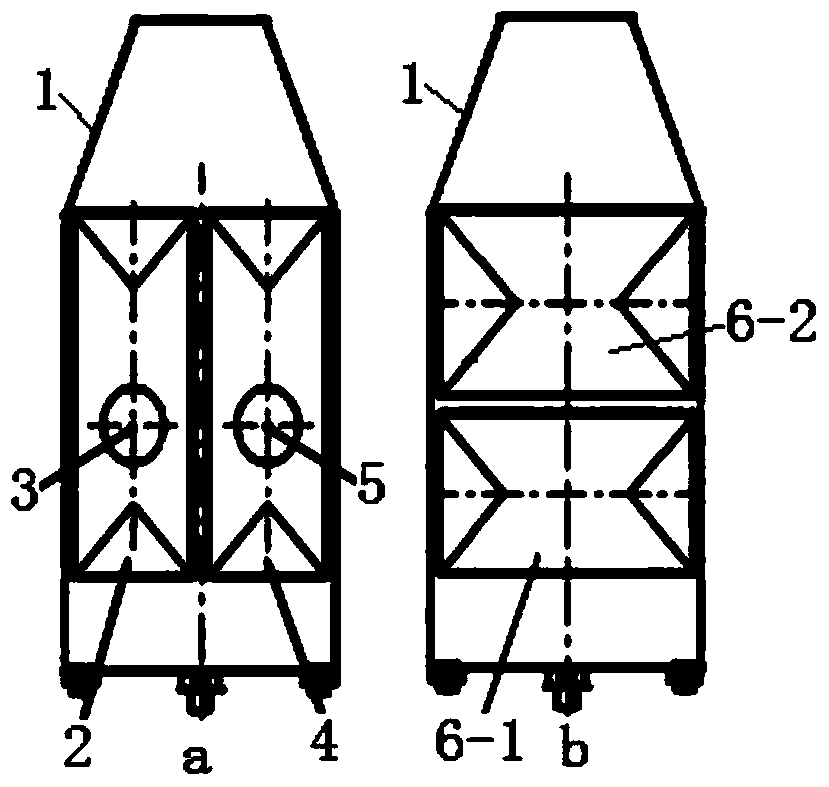

[0030] The present invention is a method for arranging water chambers of a water-cooled condenser with a multi-flow structure in the left and right directions. The front side of the water-cooled condenser has an inlet water chamber arranged in a left, middle and right direction, a fluid return bending area and an outlet water chamber. , a fluid return bend area on the front side is between the processes of the water inlet chamber and the water outlet chamber arranged left and right, and the rear side has two fluid return bends between the processes of the water inlet chamber and the outlet water chamber area, the fluid return bending areas on the rear side and front side of the condenser should be arranged correspondingly according to the flow sequence set between the inlet water chamber and the water outlet water chamber process; the function of each fluid return bending area is to The water flow from the water chamber through the heat exchange chamber is guided by turning aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com