Thermal switch automatic detection line body

An automatic detection, thermal switch technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of high cost of automatic detection devices, save workers wages, improve accuracy, and reduce personnel errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

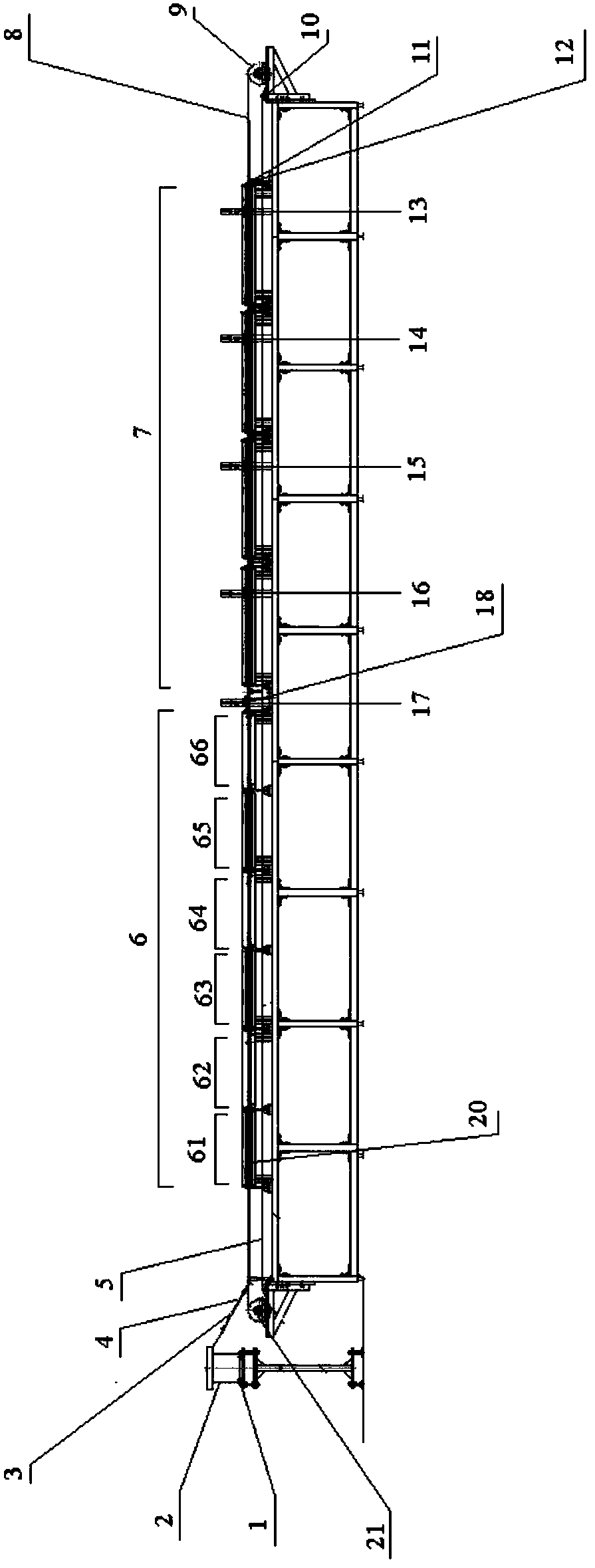

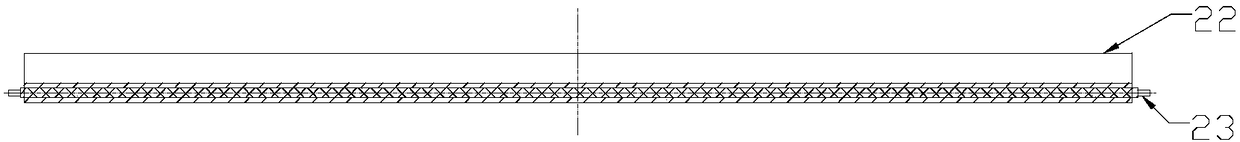

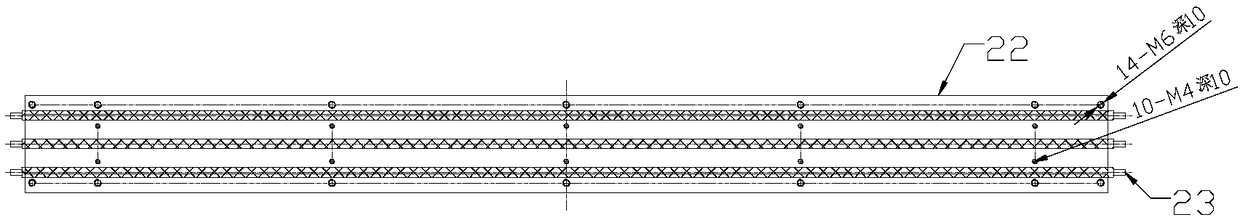

[0020] Such as Figure 1-Figure 6 As shown, the thermal switch automatic detection line body of the present invention is mainly assembled from components such as a heating chamber, a profile bracket, a stepping drive motor, a driver, a shaft coupling, and a conveyor belt. The heating chamber is fixed on the profile bracket, and the coupling will The stepping drive motor is connected with the drive wheel, the conveyor belt runs through the heating chamber synchronously with the stepping motor, and the stepping motor is controlled by the driver to make it run according to the requirements. When the temperature of the heating chamber reaches the set temperature, the vibrating tray controller sends out a pulse signal to drive the stepping motor to run, and at the same time the stepping motor drives the conveyor belt to run, and the conveyor belt runs through the heating chamber in a stepping manner. The specific components of the detection line are: vibrating tray controller 1, vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com