Array substrate and preparation method thereof, and display panel

A technology for array substrates and display panels, applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of reducing the connection reliability between pixel electrodes and drain electrodes, reducing the transmittance of display panels, and increasing the difficulty of preparing via holes, etc., to achieve Good application prospects, little impact on performance, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

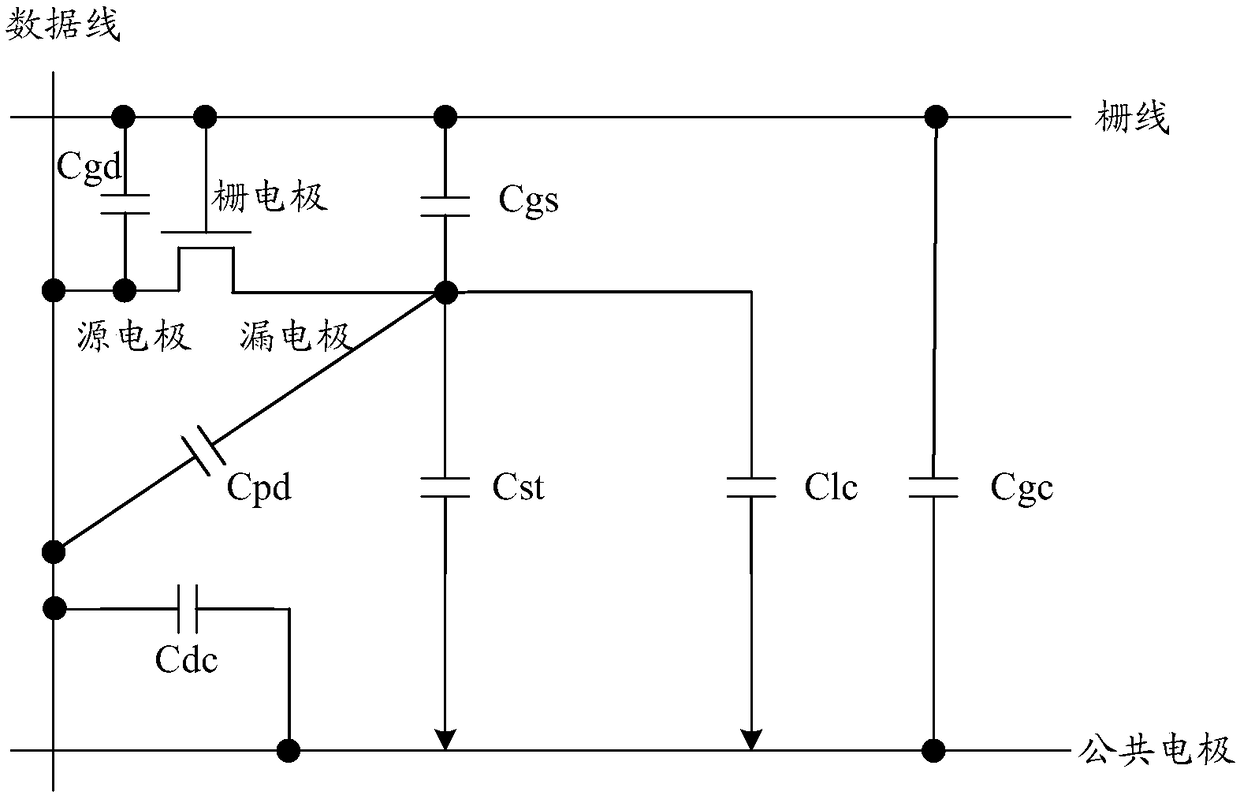

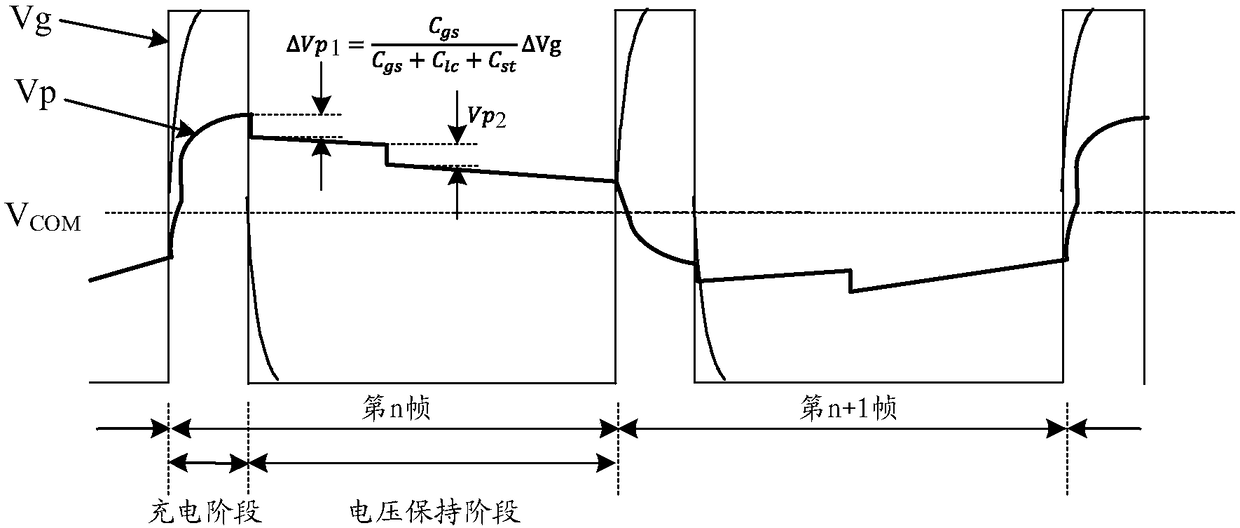

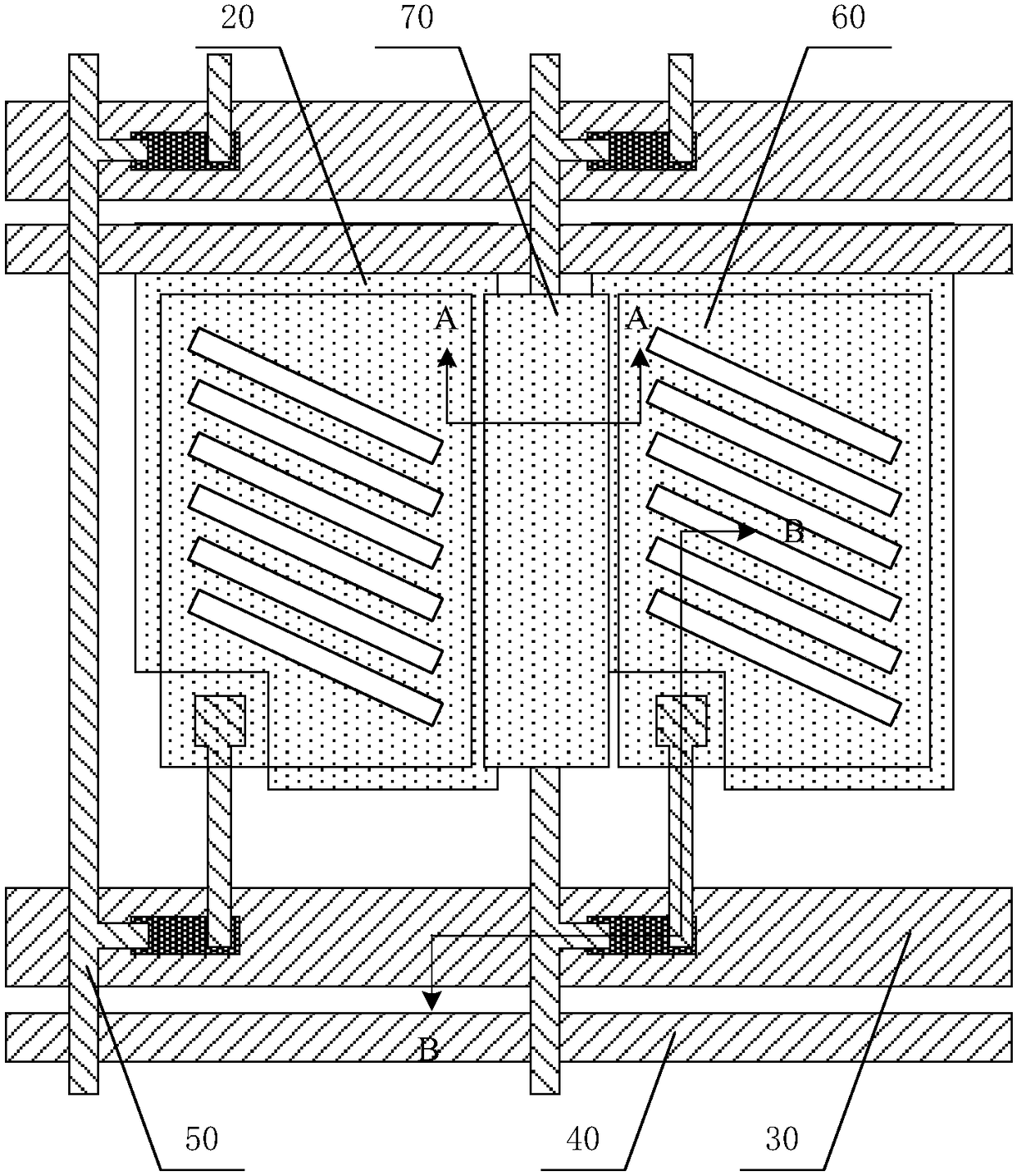

[0059] Figure 3A is a schematic structural diagram of the first embodiment of the array substrate of the present invention, Figure 3B for Figure 3A The cross-sectional view of A-A in the middle. The main structure of the array substrate in this embodiment includes a base, a plurality of gate lines and a plurality of data lines arranged on the base, the plurality of gate lines and data lines intersect each other to define a plurality of pixel areas arranged in an array, and each pixel area is set There are thin film transistors, common electrodes, pixel electrodes and shield electrodes. Such as Figure 3A and Figure 3B As shown, the array substrate of this embodiment includes a substrate 10, a common electrode 20 disposed on the substrate 10, a gate line 30, a common electrode line 40, a data line 50, a pixel electrode 60 and a shielding electrode 70, and the shielding electrode 70 covers the data line 50, and connected to the common electrode 20 through the via holes ...

no. 2 example

[0082] Figure 10A is a schematic structural diagram of the second embodiment of the array substrate of the present invention, Figure 10B for Figure 10A The cross-sectional view of A-A in the middle. The main structure of the array substrate in this embodiment includes a base, a plurality of gate lines and a plurality of data lines arranged on the base, the plurality of gate lines and data lines intersect each other to define a plurality of pixel areas arranged in an array, and each pixel area is set There are thin film transistors, common electrodes, pixel electrodes and shield electrodes. Such as Figure 10A and Figure 10B As shown, the array substrate of this embodiment includes a substrate 10, the gate lines 30, the common electrode lines 40, the pixel electrodes 60 and the shielding electrodes 70 are arranged on the substrate 10, and the gate insulating layer 12 covers the gate lines 30, the common electrode lines 40, and the pixel electrodes. electrode 60 and shi...

no. 3 example

[0102] Figure 17 is a schematic structural diagram of the third embodiment of the array substrate of the present invention, which is Figure 10A The cross-sectional view of A-A in the middle. This embodiment is a structural modification of the second embodiment, and the main structure of the array substrate is basically the same as that of the second embodiment. In the second embodiment, the common electrode is an integral structure, that is, the common electrode above the data line and the common electrode above the pixel electrode are of an integrated structure. The difference from the second embodiment is that the common electrode in this embodiment is a separate structure, that is, the common electrode above the data line and the common electrode above the pixel electrode are separate structures. Such as Figure 17 As shown, the first common electrode 20a is located above the pixel electrode 60 and is a slit electrode with a certain inclination angle, the second common...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com