Aluminum wheel extrusion casting process and device thereof

一种挤压铸造、车轮的技术,应用在制造工具、铸造设备、铸造成型设备等方向,能够解决充型速度难以控制平稳、辋气孔缺陷比例多、易发生卷气等问题,达到延伸率提升、改善材料力学性能、屈服强度提升的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

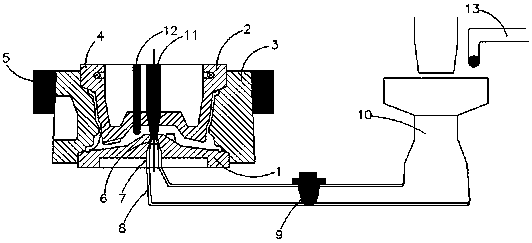

[0013] A extrusion casting process for aluminum wheels, using a U-shaped tube 8, the aluminum liquid is poured into the material barrel of the U-shaped tube 8 on one side under the control of the quantitative pump 13, and injected into the cavity from the bottom of the mold through the U-shaped tube 8, and the U-shaped The liquid surface of the mold tube 8 poured into the aluminum liquid end is equal to the highest end of the aluminum wheel casting in the mold cavity, that is, the filling of the aluminum liquid is completed.

[0014] A pressure barrel 10 is set above the barrel of the U-shaped tube 8 at the pouring end of the aluminum liquid to apply pressure to the aluminum liquid, so that the aluminum liquid in the mold cavity crystallizes and solidifies layer by layer under high pressure; At the same time of high pressure, the clamping ring 5 is set outside the side mold of the mold to apply force to the aluminum wheel casting, causing the solidified casting shell to undergo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com