Preparation system and forming method of pervious concrete

A permeable concrete and preparation system technology, applied in the direction of forming pressure head, ceramic forming machine, manufacturing tools, etc., can solve the problem that the forming method cannot guide the on-site construction well, and the forming method and forming equipment cannot be clearly given for permeable concrete The influence of performance, the lack of sufficient research on molding standards, etc., to achieve the effect of reliable technology and data support, large deformation, and reduced deformation

Inactive Publication Date: 2018-07-03

SHANDONG UNIV OF SCI & TECH

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In recent years, although permeable concrete has made great progress, there is a big difference between the experimental molding method of pervious concrete and the pavement molding process. Sufficient research, especially the existing molding methods have many uncertain factors, and the influence of molding methods and molding equipment on the performance of pervious concrete cannot be clearly given

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

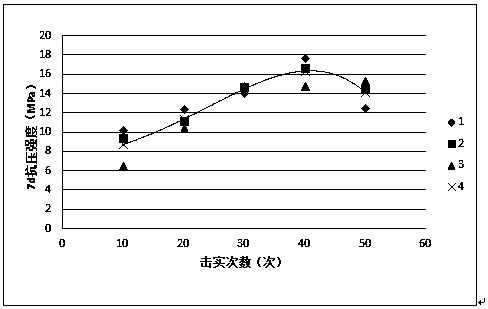

[0039] Using this molding method, lift the drop hammer to a height of 40cm, compact it 10, 20, 30, 40, and 50 times, respectively, and measure its 7d compressive strength, such as Figure 4 ; and get its 7d compressive strength curve, such as image 3 ;

[0040] Depend on image 3 It can be seen that when the compaction height is 40cm and the number of compactions is 40 times, the compressive strength is the highest.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

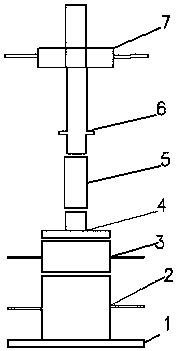

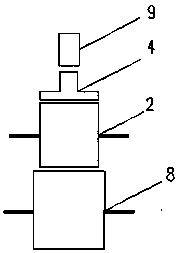

The invention discloses a preparation system and method of pervious concrete and belongs to the technical field of preparation and performance improvement of the pervious concrete. The preparation system comprises a forming device, a compaction device and a demolding device. The forming device is applied to forming of the pervious concrete. The compaction device is applied to compaction of the pervious concrete. The demolding device is applied to demolding of the pervious concrete. The preparation method comprises the steps of use of the preparation system and adjusting of the number of compaction times and the compaction height, so that the comprehensive performance of pervious concrete test blocks is improved. The preparation system and method have the beneficial effects that through a forming method and the preparation system, disadvantages of conventional forming methods ( vibration, inserting tamping and static pressing) are overcome, the strength of the pervious concrete is improved, the quantitative standard is provided for pervious concrete laboratory forming, technical and data support is further provided for on-site construction, thus the on-site construction technology is optimized, and the applicability and universality of the pervious concrete are improved.

Description

technical field [0001] The invention relates to the technical field of permeable concrete, in particular to a preparation system and a forming method of permeable concrete. Background technique [0002] At present, most cities are covered with reinforced concrete, and the road surface has poor water permeability and air permeability. Rainwater cannot penetrate into the ground in time, resulting in waterlogging on the road, and the high temperature in summer makes the road temperature rise, which brings great inconvenience to people's lives. Pervious concrete is a kind of eco-friendly concrete. It is a concrete with continuous pores made by material selection and special process. It has both a certain strength and a certain air permeability. Permeable concrete is a pavement pavement material that can not only meet the road performance, but also coordinate with the natural environment to construct a comfortable living environment for human beings. The circulation of water is ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B28B3/04B28B3/10

CPCB28B3/04B28B3/10

Inventor 单景松徐昌王敏

Owner SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com