Lubricating oil used for chain and meeting sanitary requirement of 'lubricating agent capable of being contacted with food by accident' and preparation method thereof

A technology with food contact and hygiene requirements, applied in the field of lubricating oil, can solve the problems of low volatilization rate and difficult to achieve high temperature resistance, and achieve the effects of low volatilization rate, cost control, and easy dissolution of carbon deposits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

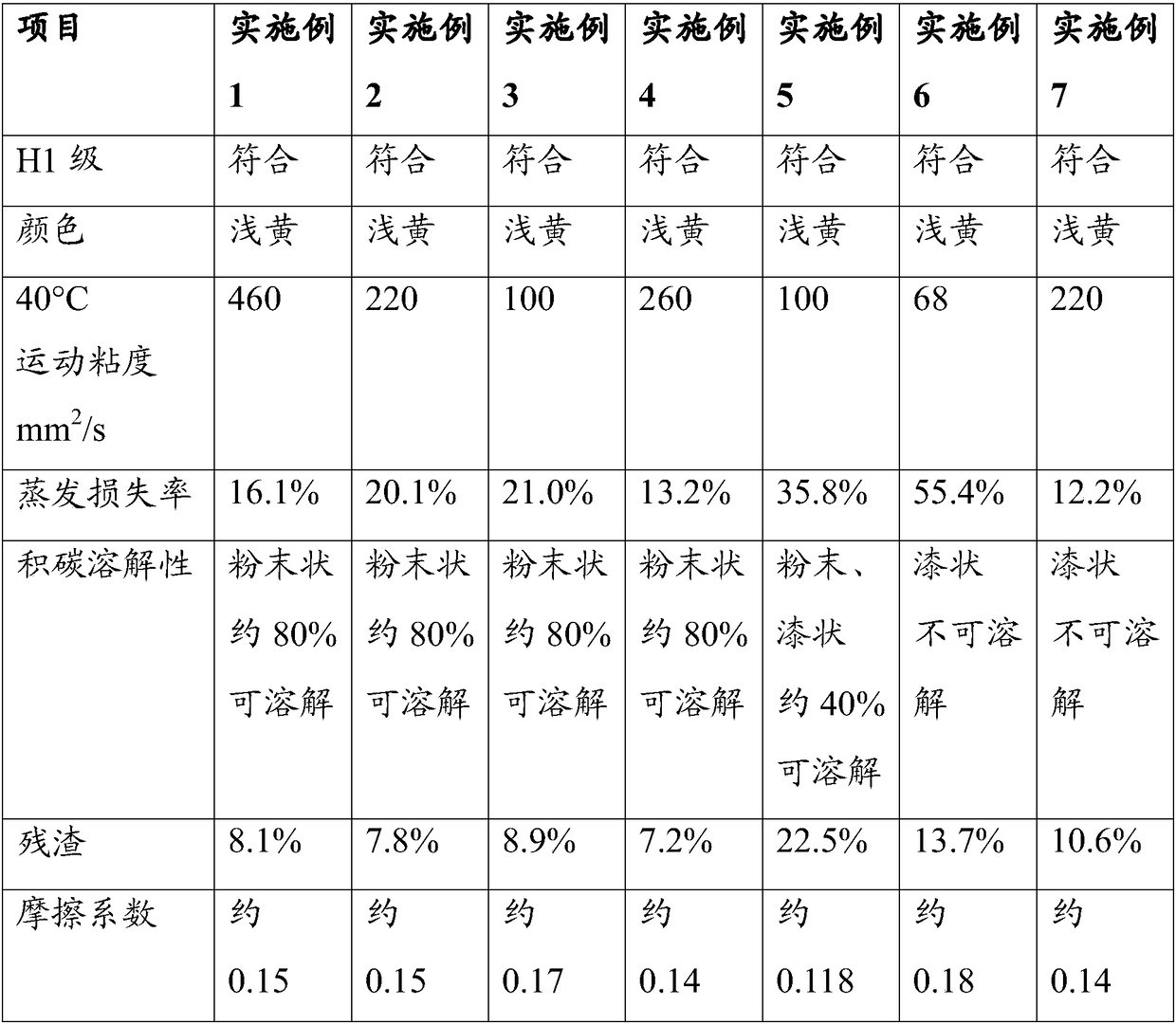

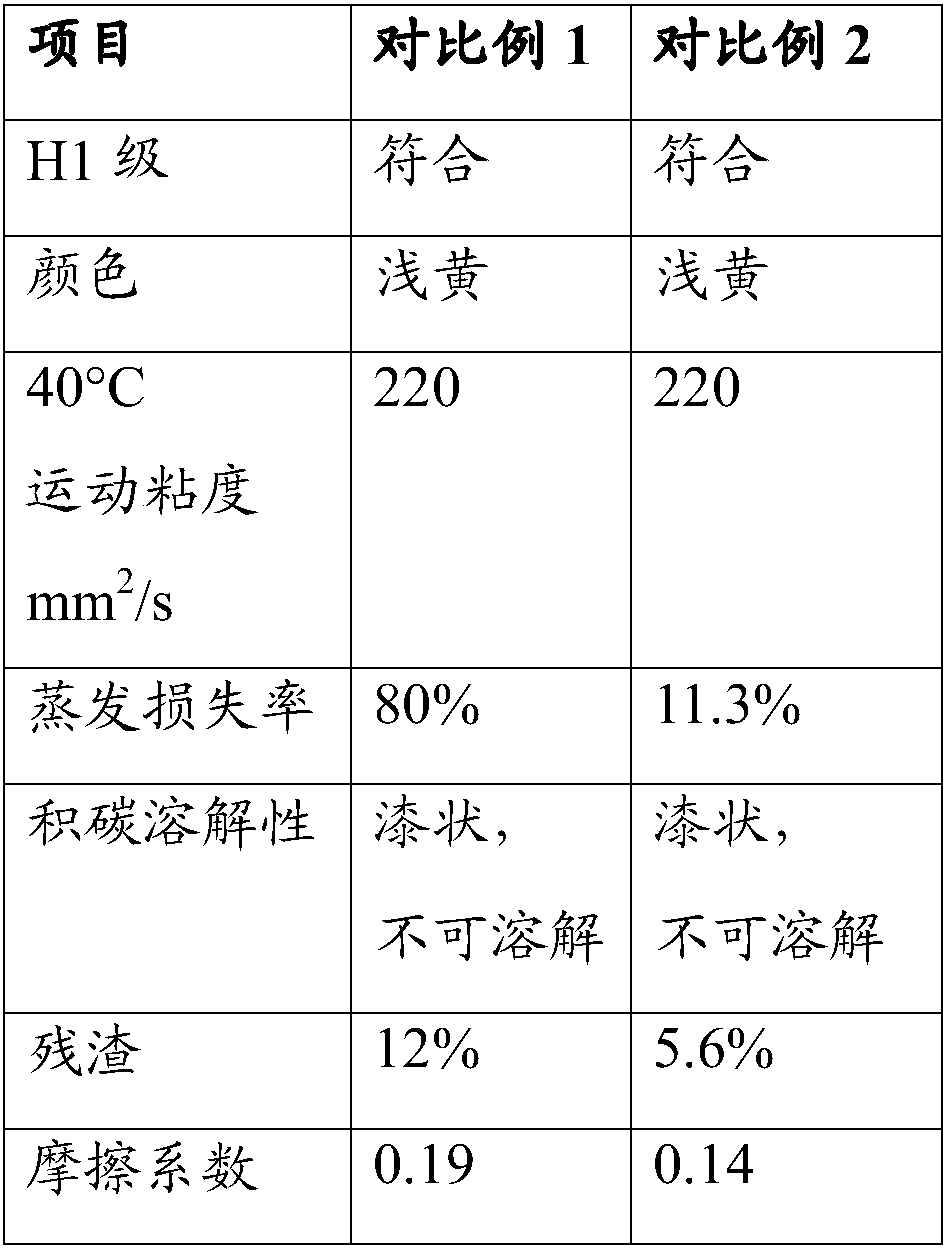

Examples

preparation example Construction

[0044] Correspondingly, the present invention also provides a preparation method of lubricating oil for chains that meets the hygienic requirements of "lubricant that occasionally comes into contact with food", comprising: providing 45-66 wt% of synthetic esters, 30-50 wt% of synthetic hydrocarbons and 1 ~9wt% additives; the synthetic ester meets the hygienic requirements of "lubricants that come into contact with food accidentally"; the synthetic hydrocarbon meets the hygienic requirements of "lubricants that come into contact with food accidentally"; Lubricants" hygienic requirements.

[0045] Specifically, the step of providing the synthetic ester, the synthetic hydrocarbon, and the additive includes: putting the synthetic ester, the synthetic hydrocarbon, and the additive into a reactor; putting the synthetic ester, the synthetic hydrocarbon And in the step of mixing the additives and constant temperature stirring to obtain the chain lubricating oil, the process temperatur...

Embodiment 1

[0049] Mix 45wt% of trimellitate, 38wt% of PAO40, 12wt% of butene homopolymer and 5wt% of additives, and stir at a constant temperature of 70°C to 80°C for 30 minutes to obtain a lubricating oil for chains. Among them, trimellitate and additives meet the health requirements of the National Sanitation Foundation HX-1; PAO40 and butene homopolymer meet the health requirements of the National Sanitation Foundation H-1.

Embodiment 2

[0051] Mix 50wt% of trimellitate, 30wt% of PAO6, 15wt% of butene homopolymer and 5wt% of additives, and stir at a constant temperature of 70°C to 80°C for 30 minutes to obtain a lubricating oil for chains. Among them, trimellitate and additives meet the health requirements of the National Sanitation Foundation HX-1; PAO6 and butene homopolymer meet the health requirements of the National Sanitation Foundation H-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com