Stoving method for improving paddy rice quality

A quality, rice technology, applied in food drying, material inspection products, seeds preservation by drying, etc., can solve the problems of reduced nutrition, reduced rate of whole milled rice, and increased rate of rice popping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention is described in detail below in conjunction with embodiment. In order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the present invention will be described in further detail below with reference to the accompanying drawings and examples, but the present invention is not limited to these examples.

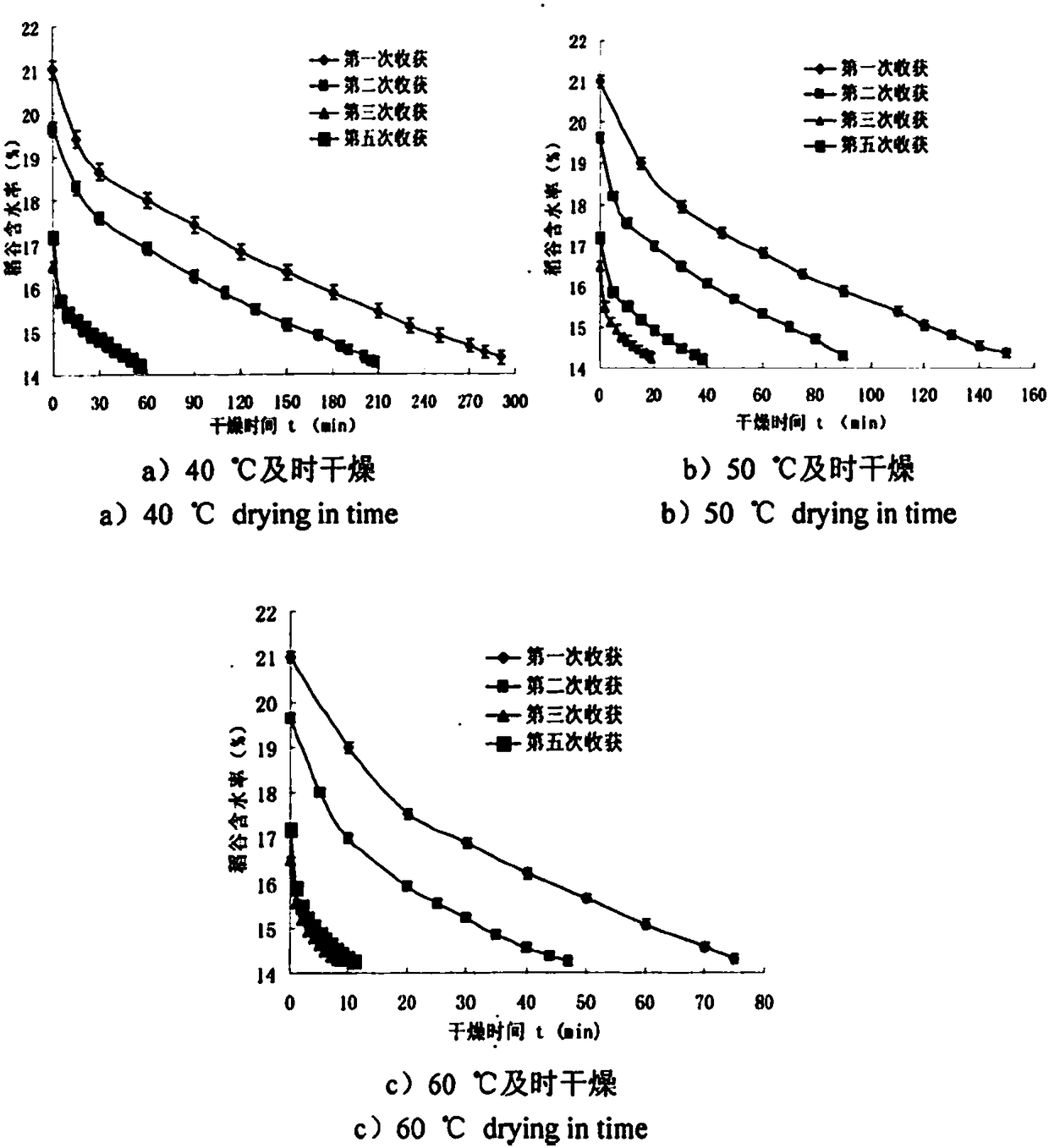

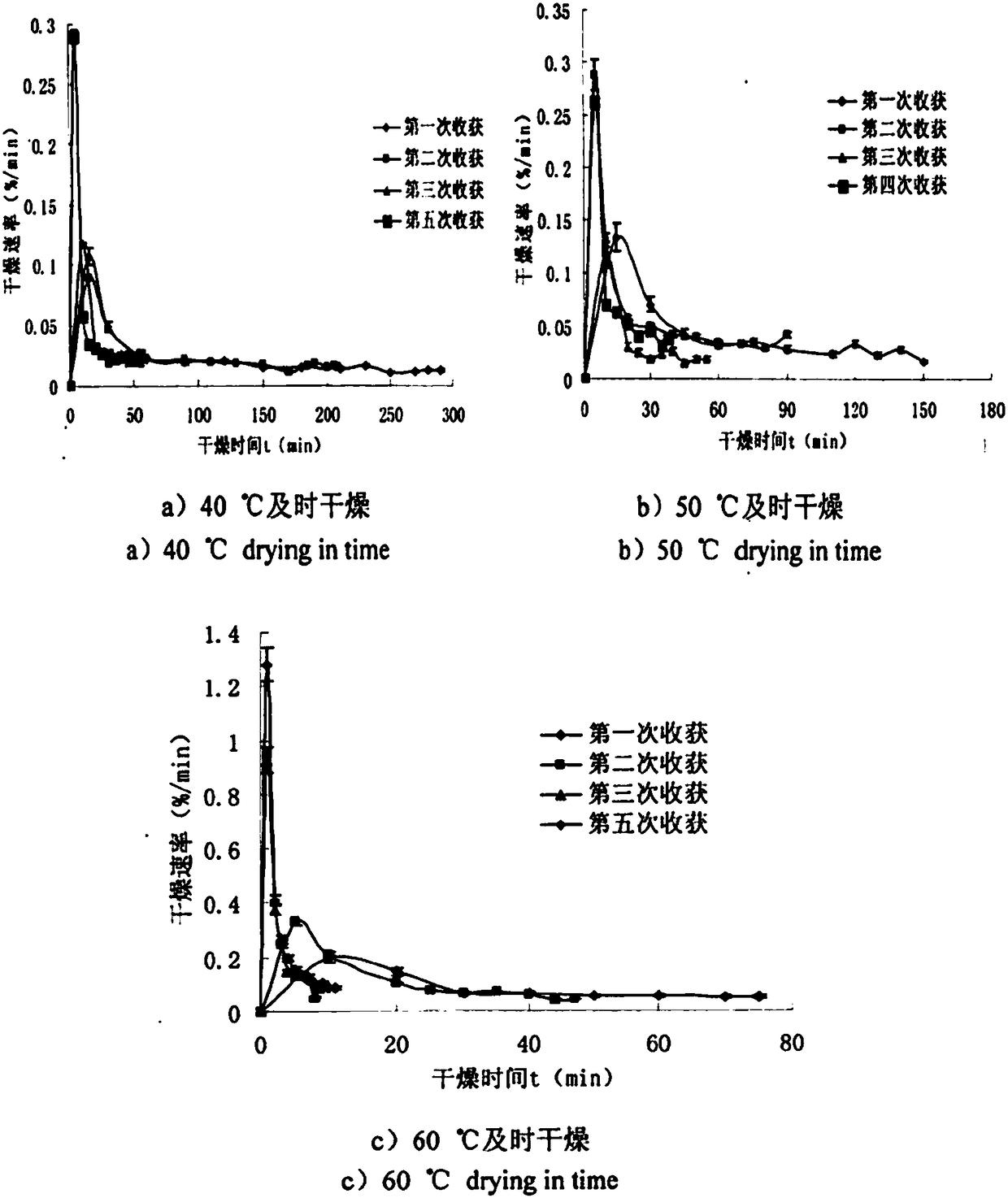

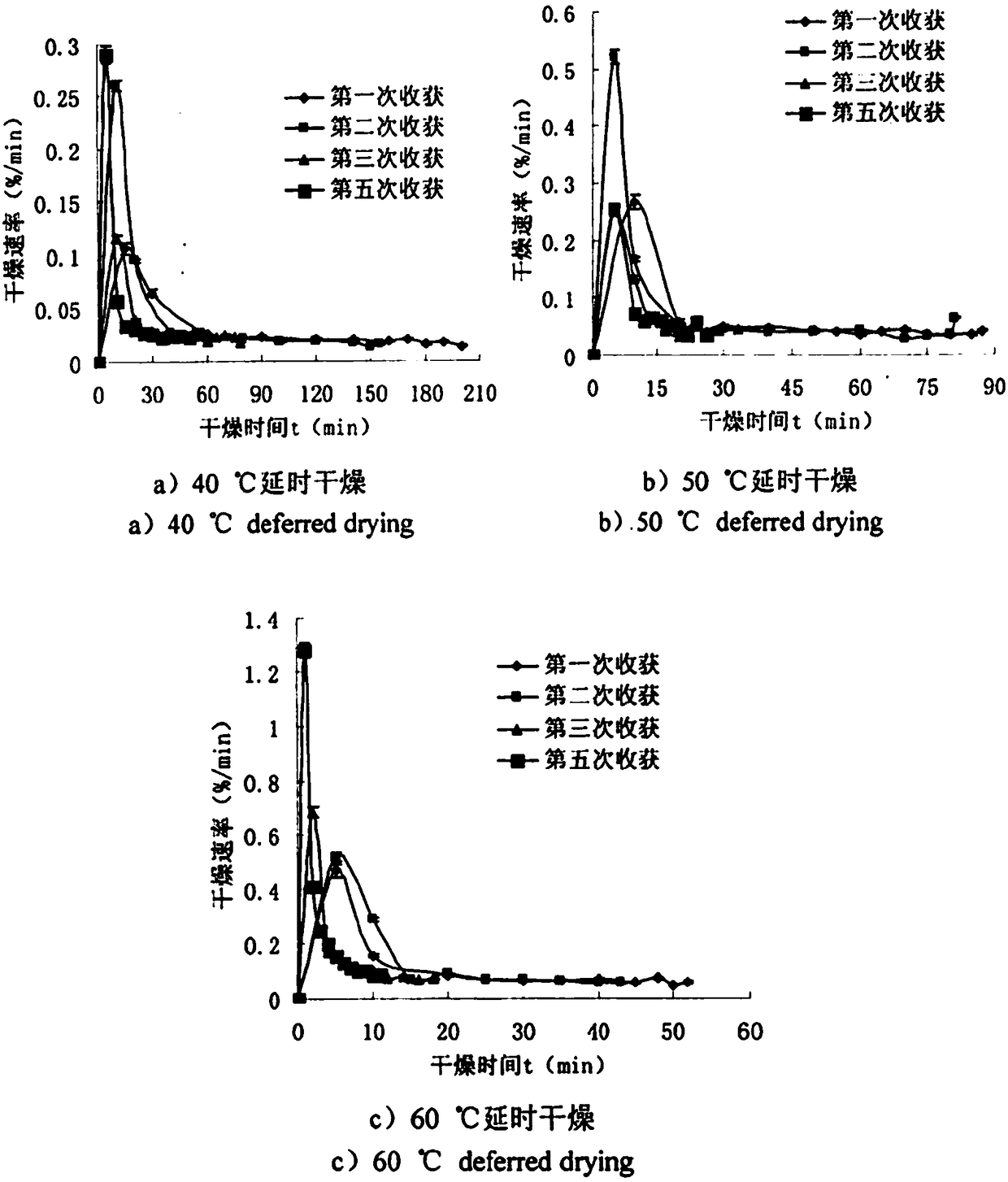

[0051] The purpose of the present invention is to seek the best drying method on the premise of ensuring the production quality and eating quality of rice. The timely drying method was compared with the traditional delayed drying method, and combined with related drying experiments, the bursting rate of rice at different temperatures was studied.

[0052] In order to solve the above-mentioned technical problems, the present invention provides a drying method for improving rice quality, comprising the following steps:

[0053] A. The rice is harvested one day after the ripening period begins, and sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com