A kind of tobacco puffing production process

A production process and tobacco technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of no way to isolate oxygen, lack of vacuum, and tobacco ignition and combustion, and achieve the effects of fast speed, high heating efficiency, and fast puffing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

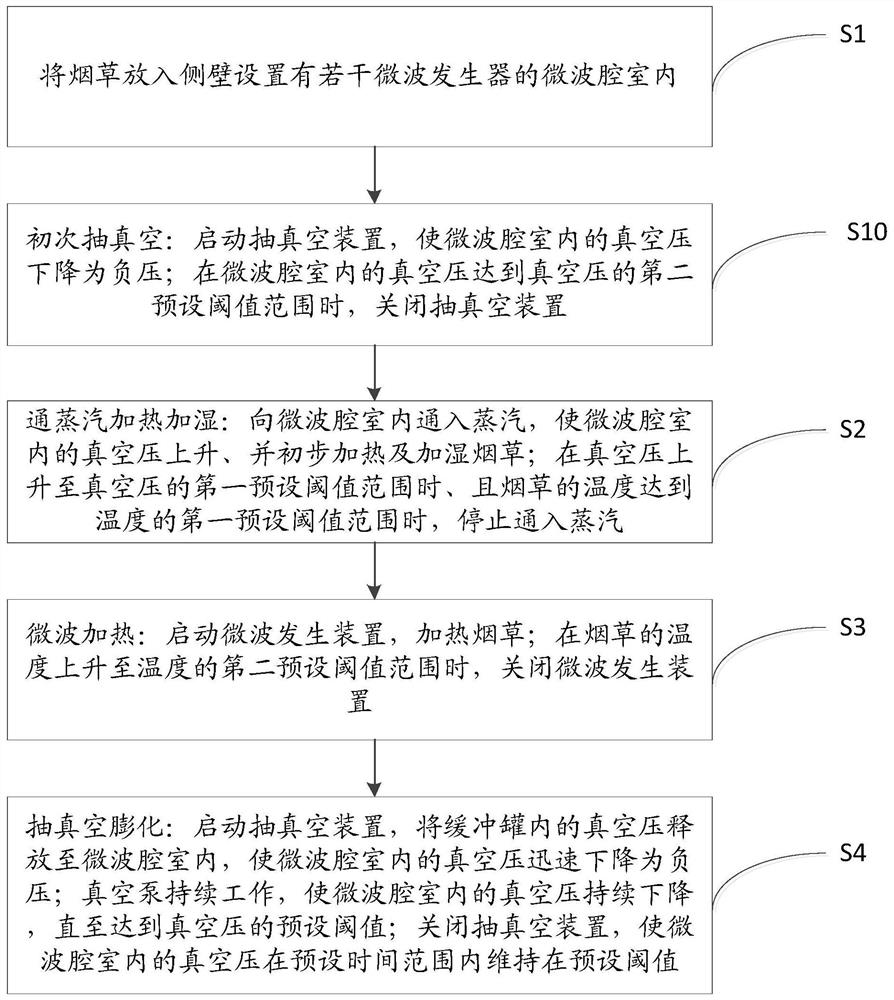

[0024] See figure 1 , Is the flow chart of the tobacco puffing process provided in this embodiment. The tobacco puffing process includes the following steps:

[0025] S1: Put tobacco into a microwave cavity with several microwave generators on the side wall.

[0026] S10: First vacuuming: start the vacuuming device to reduce the vacuum pressure in the microwave chamber to a negative pressure; when the vacuum pressure in the microwave chamber reaches the second preset threshold range of the vacuum pressure, the vacuuming device is closed.

[0027] This step is used for vacuuming. Vacuum the microwave chamber before the steaming process. On the one hand, it can cut off the air and prevent the tobacco from burning due to high temperature during the microwave heating process; on the other hand, it can draw off the air attached to the tobacco surface, making it In the steaming process, the steam can fully and completely contact the tobacco, and the humidification effect is good; on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com