Interlayer conical cover dispersing component and method for dispersing liquid phase

A dispersing element, conical technology, applied in the direction of liquid solution solvent extraction, etc., can solve the problems of excessive coacervate height, difficulty in forming a stable coacervate height on the tray, and reduced mass transfer efficiency in the mass transfer zone, so as to increase the extraction rate , easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

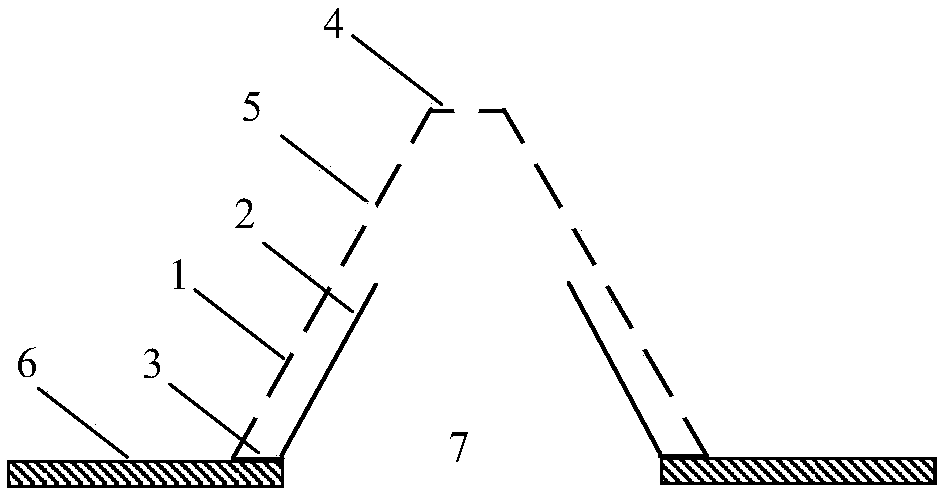

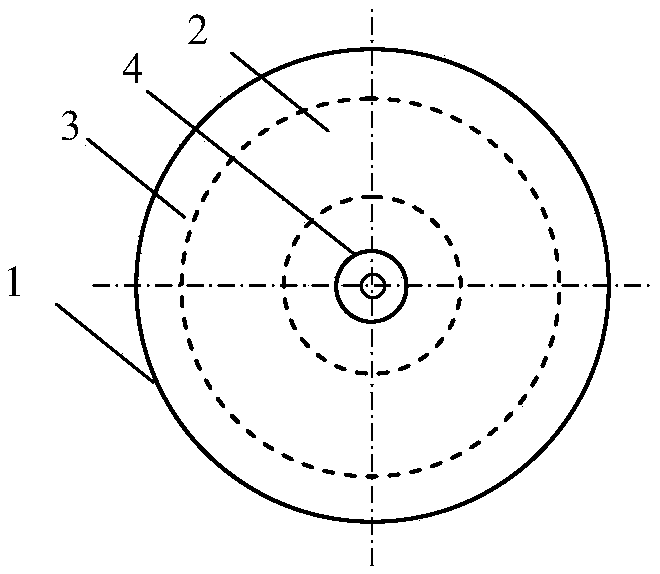

[0043] figure 1 with figure 2A diagram representing the structure of a sandwich conical hood dispersing element. Wherein, the vertical section of outer conical cover 1 is an isosceles trapezoid; the diameter of the bottom end of outer conical cover 1 is 80 mm, the diameter of the top is 12 mm, and the height of conical cover is 60 mm; the diameter of the bottom end of inner conical tube 2 is It is 64mm, the diameter of the top is 30mm, and the height of the conical tube is 30mm.

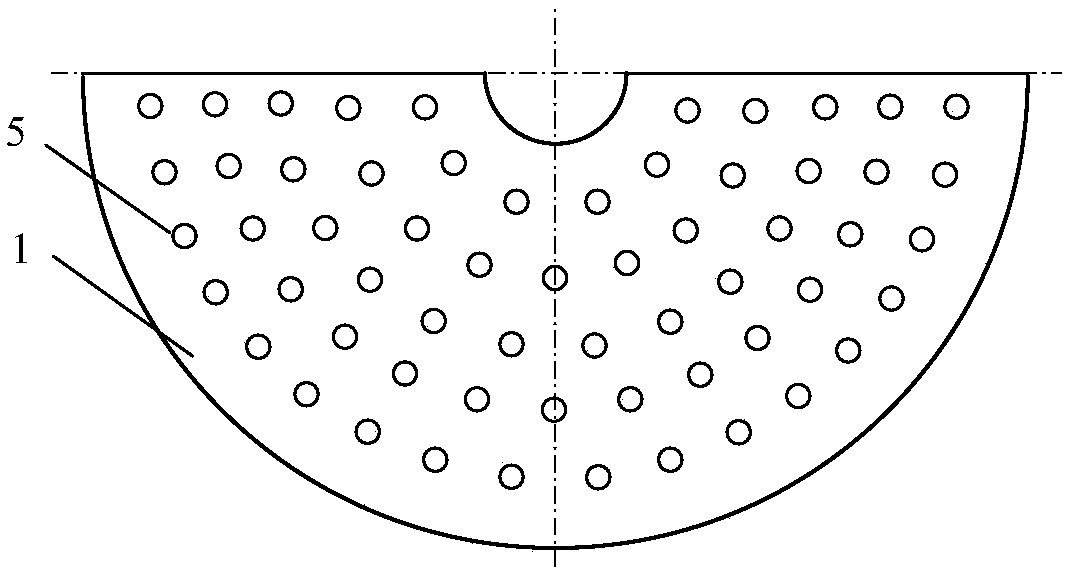

[0044] The side expansion diagram of the outer layer conical cover 1 is as image 3 As shown, it is a semi-circular ring-shaped sieve plate, on which 5 rows of circular sieve holes 5 are arranged at equal intervals in a concentric circle manner. Each row of circular screen holes 5 is at the same height after forming a conical surface. The vertical heights of the center of each row of screen holes from the lower annular bottom plate 3 are 10mm, 20mm, 30mm, 40mm and 50mm respectively. Each row of c...

Embodiment 2

[0048] figure 1 and figure 2 A diagram representing the structure of a sandwich conical hood dispersing element. Wherein, the vertical section of outer conical cover 1 is an isosceles trapezoid; the diameter of the bottom end of outer conical cover 1 is 60mm, the diameter of the top is 9mm, and the height of conical cover is 45mm; the diameter of the bottom end of inner conical tube 2 is It is 48mm, the diameter of the top is 22.5mm, and the height of the conical tube is 22.5mm.

[0049] The side expansion diagram of the outer layer conical cover 1 is as image 3 As shown, it is a semi-circular ring-shaped sieve plate, on which 5 rows of circular sieve holes 5 are arranged at equal intervals in a concentric circle manner. Each row of circular screen holes 5 is at the same height after being surrounded by a conical surface, and the vertical heights of each row of screen hole centers from the lower annular bottom plate 3 are 7.5mm, 15mm, 22.5mm, 30mm and 37.5mm respectively....

Embodiment 3

[0053] Figure 4 and Figure 5 A diagram representing the structure of a sandwich conical hood dispersing element. Wherein, the vertical section of the outer conical cover 1 is an isosceles trapezoid; the diameter of the bottom end of the outer conical cover 1 is 80 mm, the diameter of the top is 35 mm, and the height of the conical cover is 40 mm; the diameter of the bottom end of the inner conical tube 2 is It is 64mm, the diameter of the top is 30mm, and the height of the conical tube is 30mm.

[0054] The side expansion diagram of the outer layer conical cover 1 is as Figure 6 As shown, it is a semi-circular ring-shaped sieve plate, on which 3 rows of circular sieve holes 5 are arranged at equal intervals in a concentric circle manner. Each row of circular sieve holes 5 is at the same height after being surrounded by a conical surface. The vertical heights of the center of each row of sieve holes from the lower annular bottom plate 3 are respectively 10mm, 20mm and 30m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com