Flotation atomization dosing device

A dosing device and flotation technology, applied in flotation, solid separation, etc., can solve the problems of difficult control of dosing volume, complex equipment structure, and unbalanced mass distribution, so as to shorten the time of slurry preparation, improve production efficiency, The effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

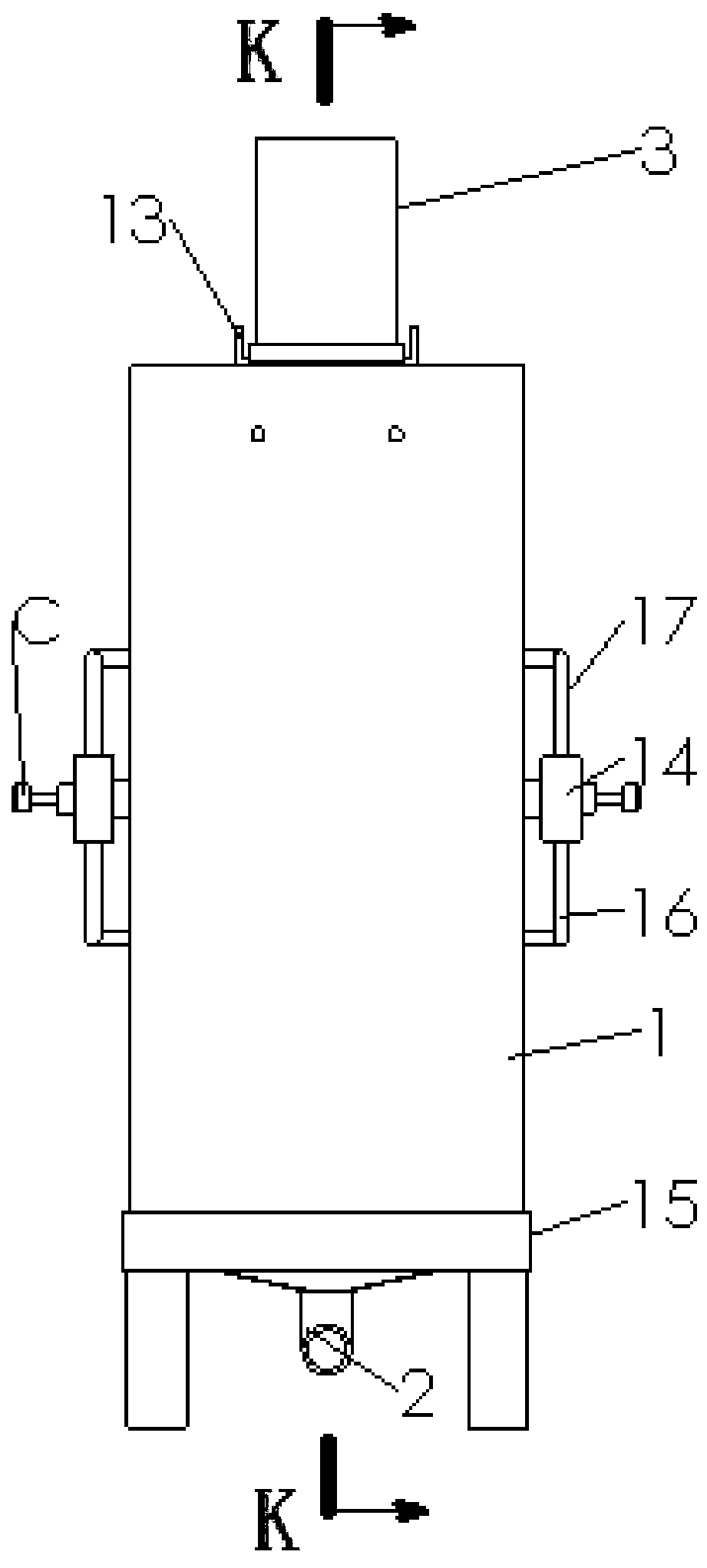

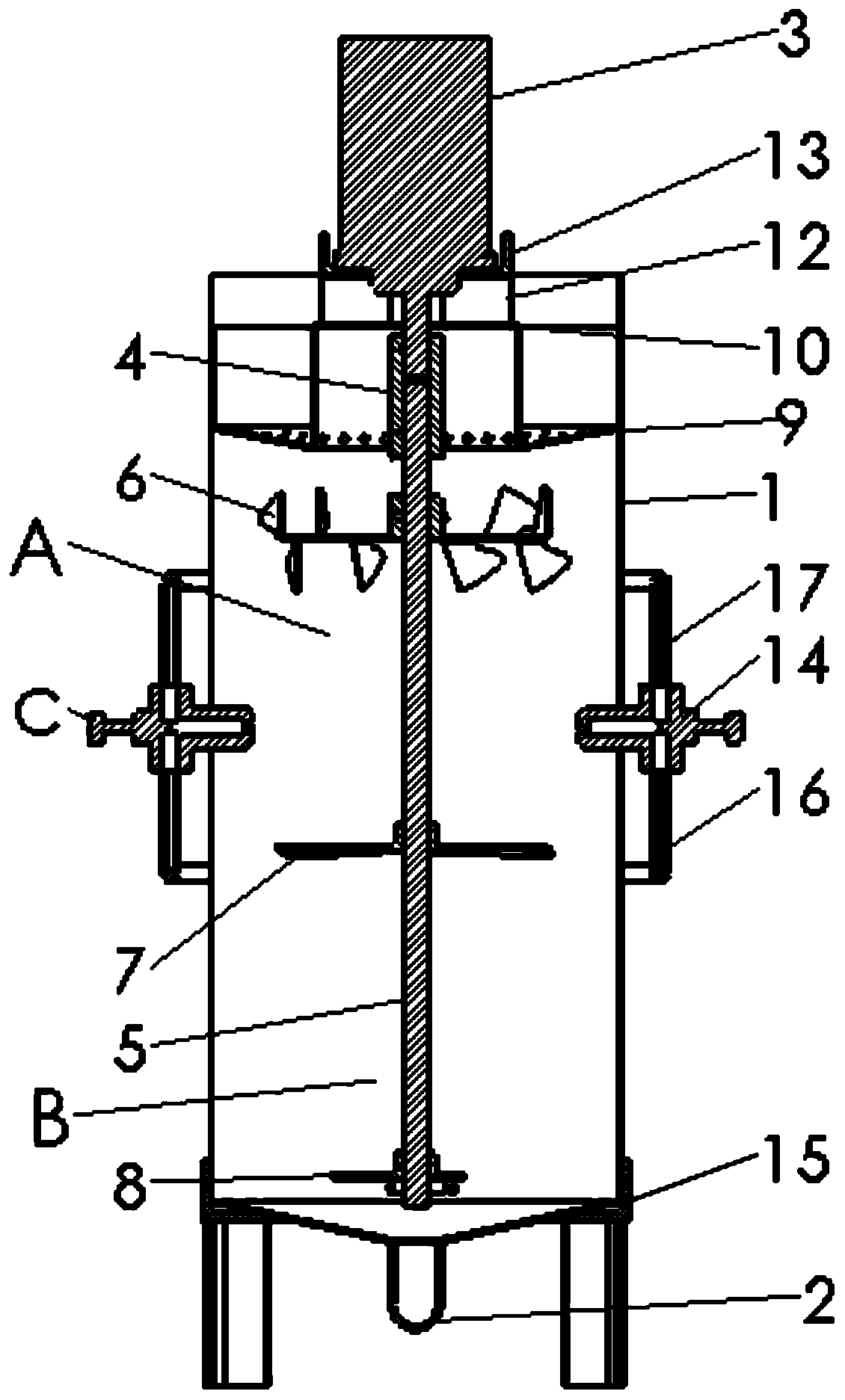

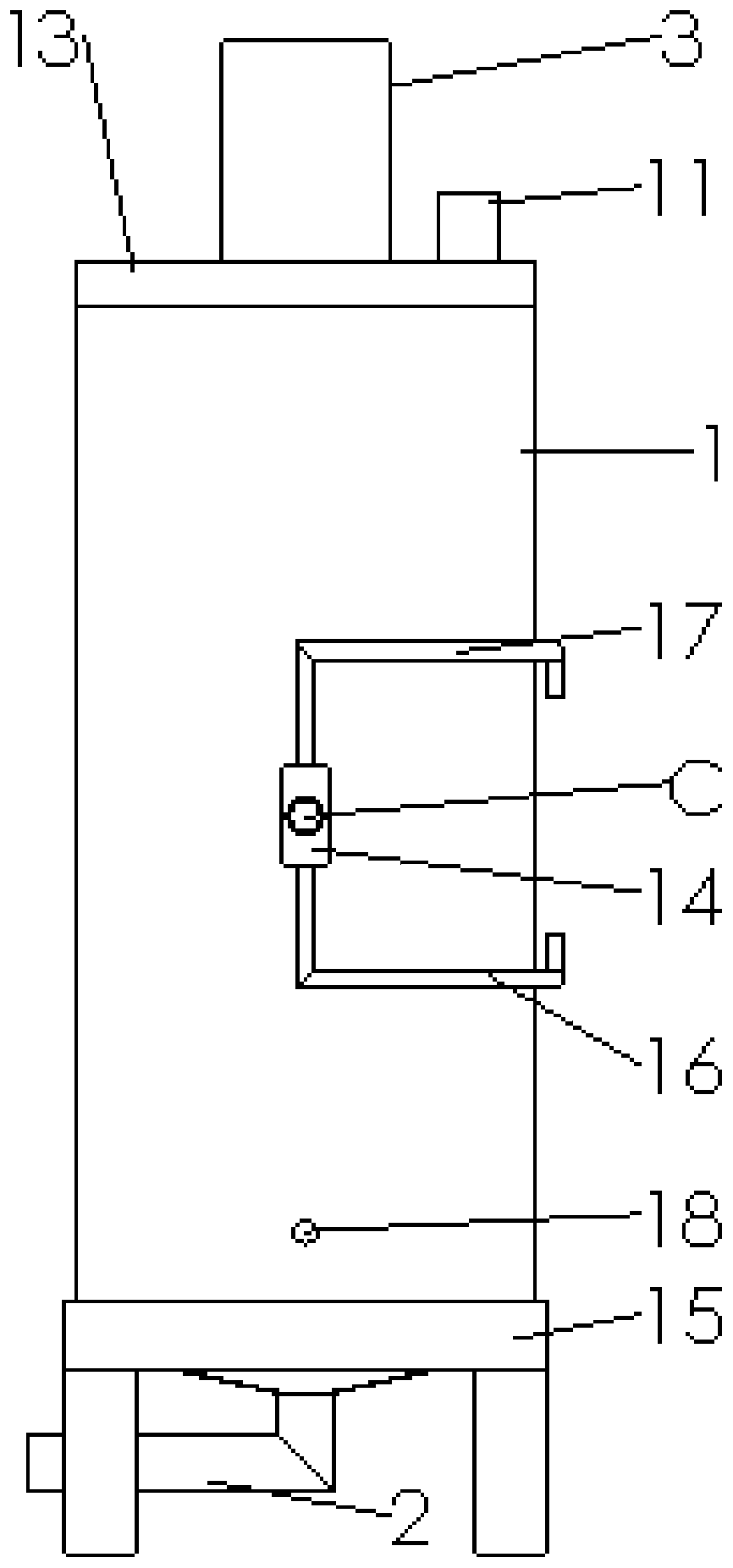

[0046] refer to Figure 1 to Figure 25As shown, the flotation atomization dosing device in an embodiment provided by the present invention includes a barrel body 1, a pulp dispersion mechanism A, a chemical atomization mechanism B and a pulp stirring mechanism D, and the upper end of the barrel body 1 is provided with an ore feeder Pipe 11, pulp dispersing mechanism A and pulp stirring mechanism D are arranged in barrel body 1, and the lower end of barrel body 1 is provided with ore discharge pipeline 2, wherein, pulp stirring mechanism D includes stirring spindle 5, and stirring spindle 5 is provided with stirring impeller 8. The pulp dispersing mechanism is set above the stirring impeller. The chemical atomizing mechanism B includes an atomizing nozzle 14, which is arranged on the inner wall of the barrel body 1. The ore pulp enters the barrel body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com