Method for centrally removing PM2.5 and heavy/alkali metal in iron ore sintering flue gas

A technology for sintering flue gas and alkali metals, which is applied in the treatment of iron ore sintering flue gas, and concentrated removal of PM2.5 and heavy/alkali metals in iron ore sintering flue gas, which can solve the problem of large flow rate of sintering flue gas and low emission concentration , The process adsorption technology cannot adapt to the sintering demand and other problems, to achieve the effect of prolonging the service life, stable and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

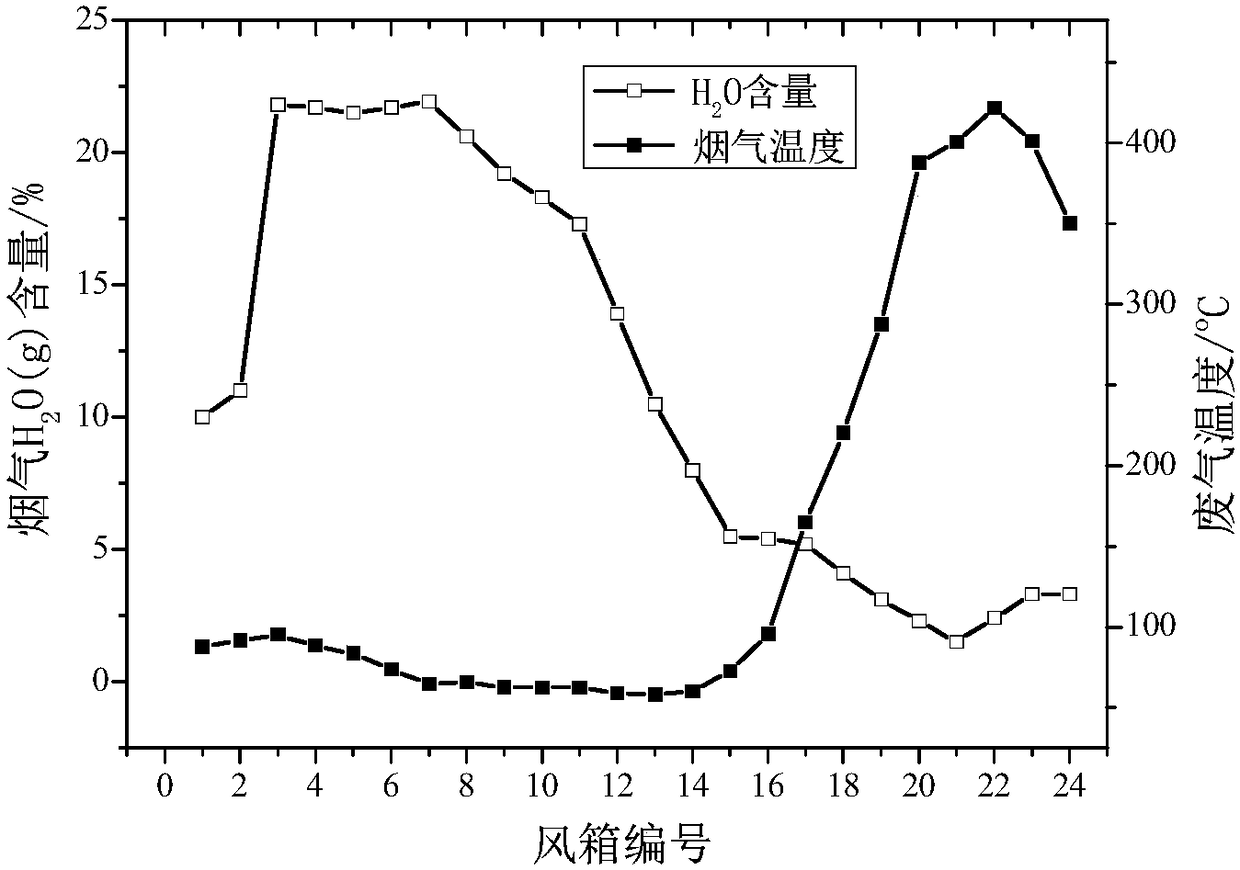

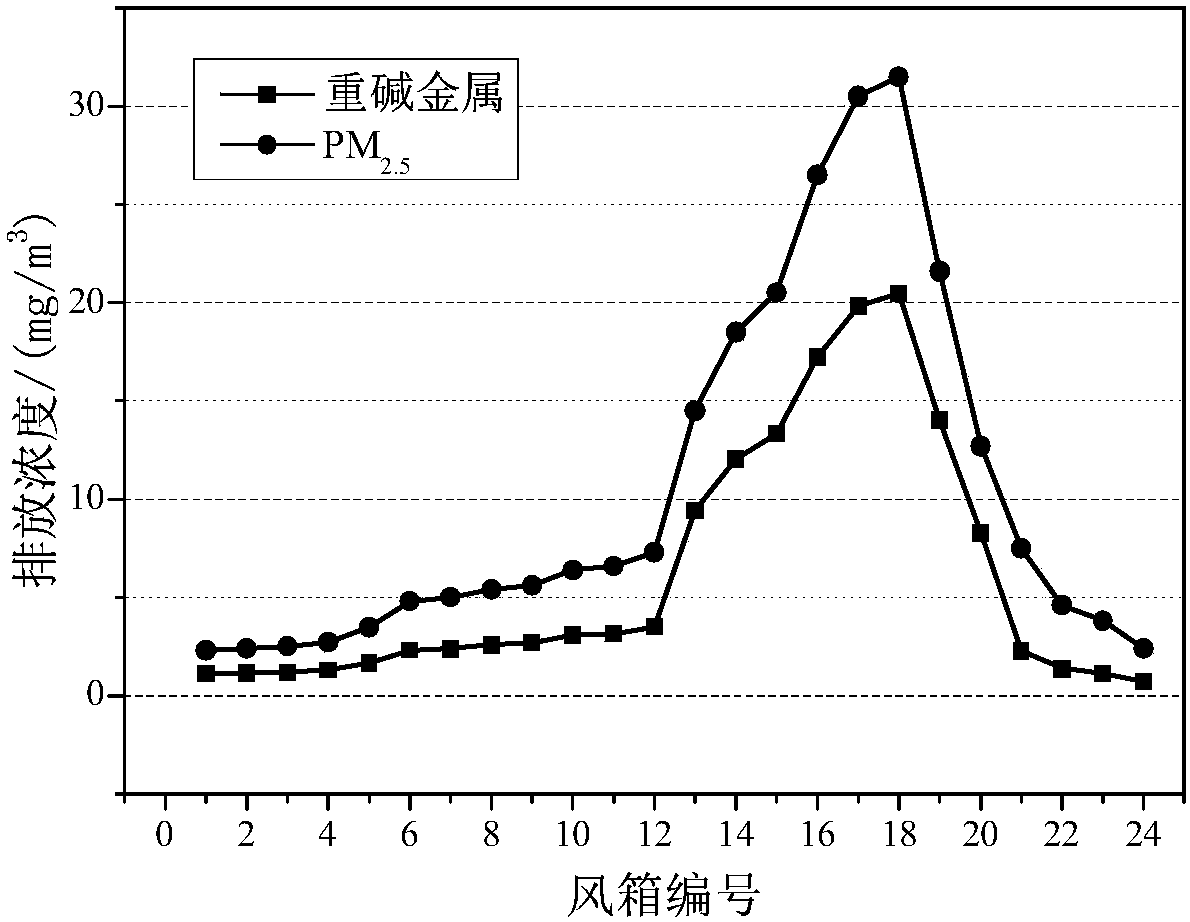

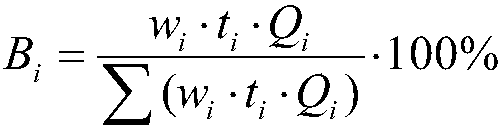

[0033] According to the temperature of flue gas in different bellows, H 2 O(g) content (see figure 1 ) and PM 2.5 , heavy / alkali metal emission concentrations (see figure 2 ), the sintering flue gas is divided into three sections: the first section of the sintering stage is 1 # -13 # Bellows; 14 in the middle of the sintering stage # -20 # Bellows; sintering stage tail section is 21 # -twenty four # bellows. Flue gas temperature at different stages, H 2 O(g) content and PM 2.5The proportion of heavy / alkali metal emissions to total emissions is shown in Table 1. The flue gas discharged from the front and end of sintering is introduced into the low-emission flue, and the conventional electrostatic precipitator is used for dust removal. The flue gas discharged from the middle part of the sintering is introduced into the high-emission flue, and filtered by a ceramic filter membrane, and the purification efficiency is as high as 95.5%. Then, the purified high-emission ...

Embodiment 2

[0035] According to the temperature of flue gas in different bellows, H 2 O(g) content (see figure 1 ) and PM 2.5 , heavy / alkali metal emission concentrations (see figure 2 ), the sintering flue gas is divided into three sections: the first section of sintering is 1 # -14 # Bellows; 15 mid-sinter section # -20 # Bellows; burn end section is 21 # -twenty four # bellows. Flue gas temperature at different stages, H 2 O(g) content and PM 2.5 The proportion of heavy / alkali metal emissions to total emissions is shown in Table 1. The flue gas discharged from the front and end of sintering is introduced into the low-emission flue, and the conventional electrostatic precipitator is used for dust removal. The flue gas discharged from the middle section of sintering is introduced into the high-emission flue, and filtered by a metal fiber membrane, and the purification efficiency is as high as 96.8%. Then, the purified high-emission flue gas is recovered by the waste heat rec...

Embodiment 3

[0037] According to the temperature of flue gas in different bellows, H 2 O(g) content (see figure 1 ) and PM 2.5 , heavy / alkali metal emission concentrations (see figure 2 ), the sintering flue gas is divided into three sections: the first section of sintering is 1 # -14 # Bellows; 15 mid-sinter section # -twenty one # Bellows; burn end is 22 # -twenty four # bellows. Flue gas temperature at different stages, H 2 O(g) content and PM 2.5 The proportion of heavy / alkali metal emissions to total emissions is shown in Table 1. The flue gas discharged from the front and end of sintering is introduced into the low-emission flue, and the conventional electrostatic precipitator is used for dust removal. The flue gas emitted from the middle section of sintering is introduced into the high-emission flue, and filtered by the intermetallic compound membrane, and the purification efficiency is as high as 98.5%. Then, the purified high-emission flue gas is recovered by the wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com