Large high-rise mechanical equipment washing equipment

A cleaning equipment and high-level technology, applied in the direction of lifting devices, cleaning methods and tools, cleaning methods using tools, etc., can solve problems such as danger, dirty appearance, no way to paint, etc., and achieve a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

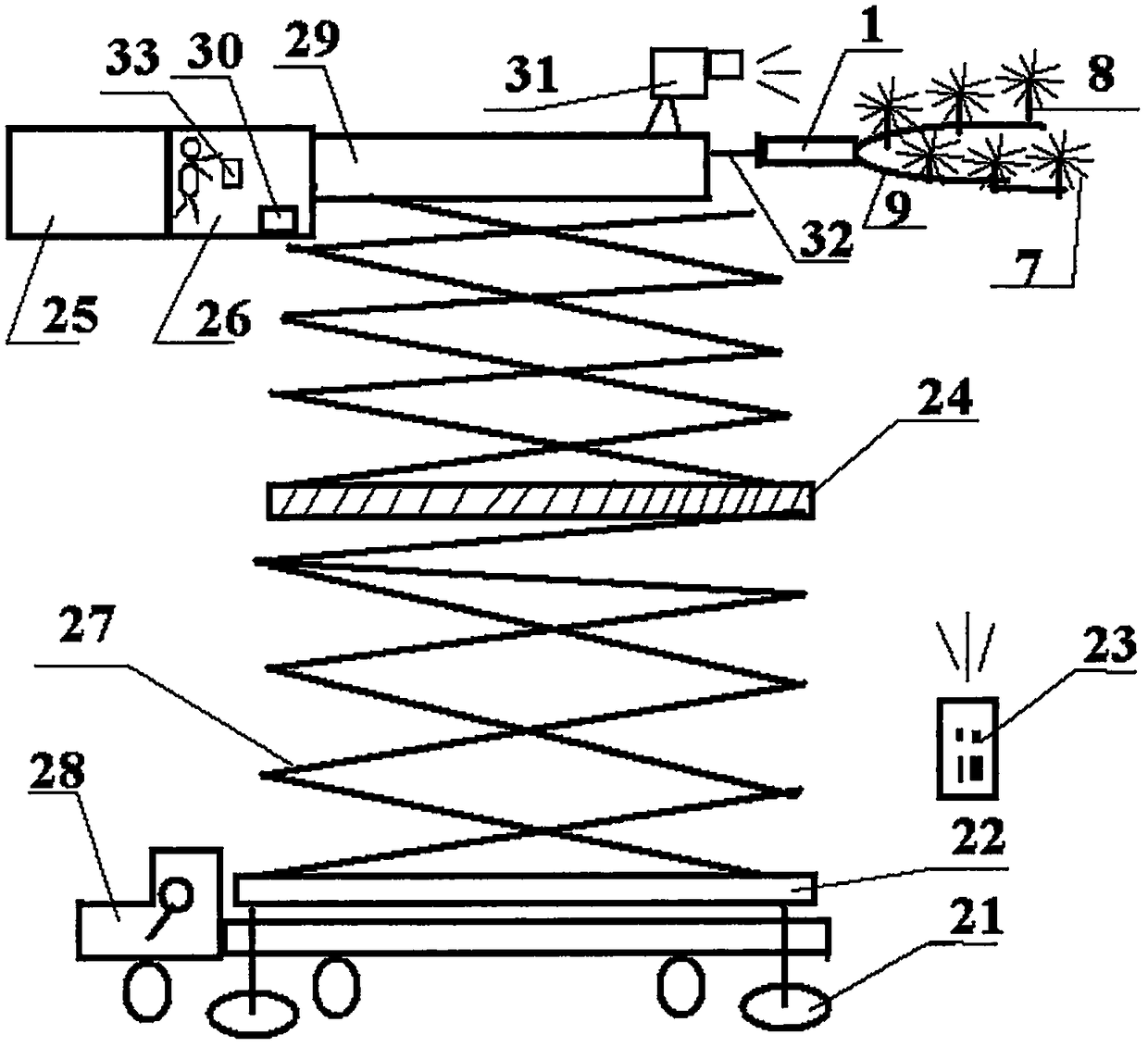

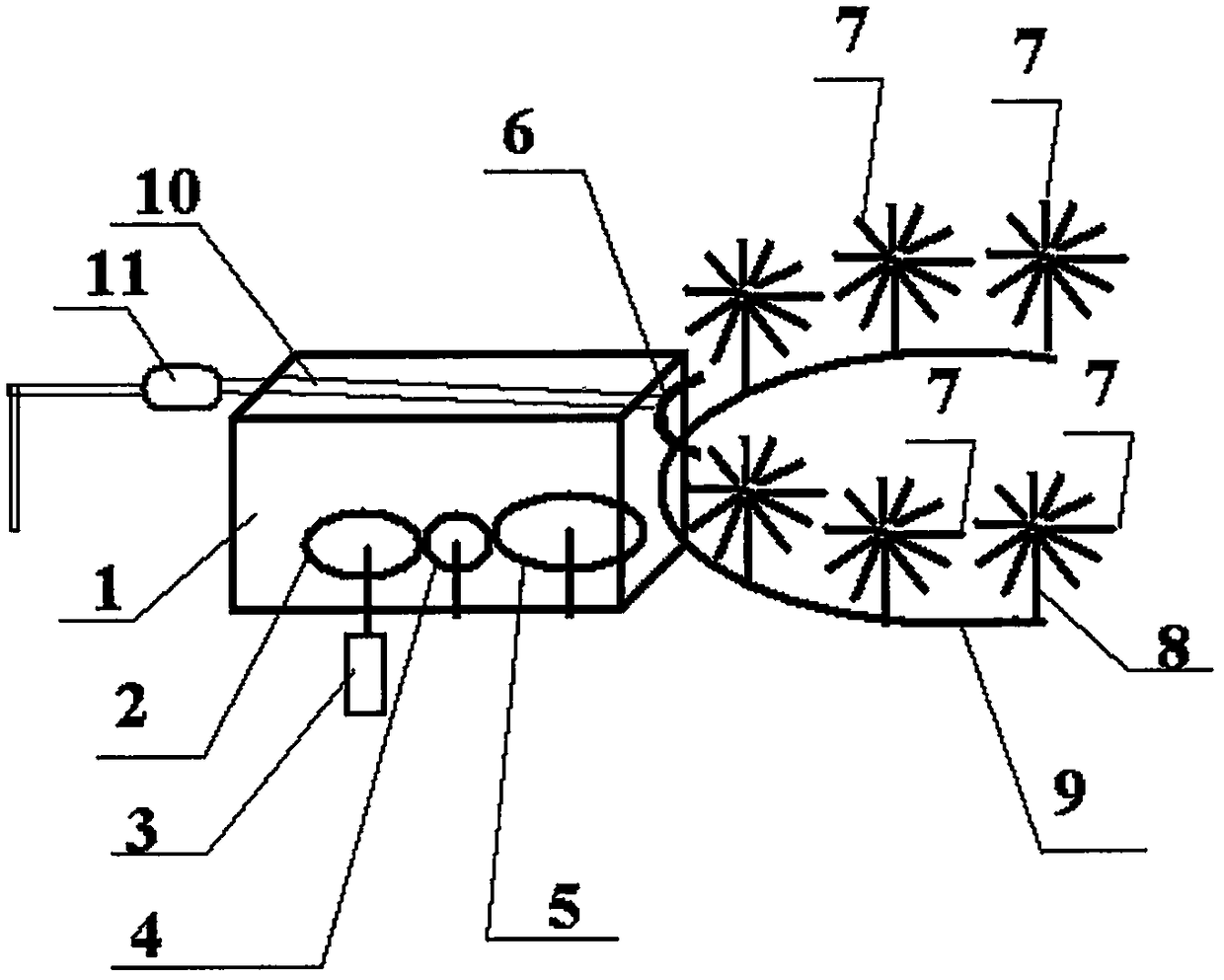

[0029] Such as figure 1 As shown, when a certain tall mechanical equipment or electrical equipment needs to be cleaned, the truck 28 can be driven to the required site, and the present invention can be controlled by the remote control 23 and can also be controlled by the touch screen in the observation room 26. Equipment, the touch screen of the present invention is a surface acoustic wave touch screen, the surface acoustic wave touch screen is not affected by environmental factors such as temperature and humidity, has extremely high resolution, excellent scratch resistance, long life (50 million times without failure), and can keep clear Transparent image quality, no drift, only one correction during installation, and third axis (ie pressure axis) response, most suitable for the present invention to be used in public places.

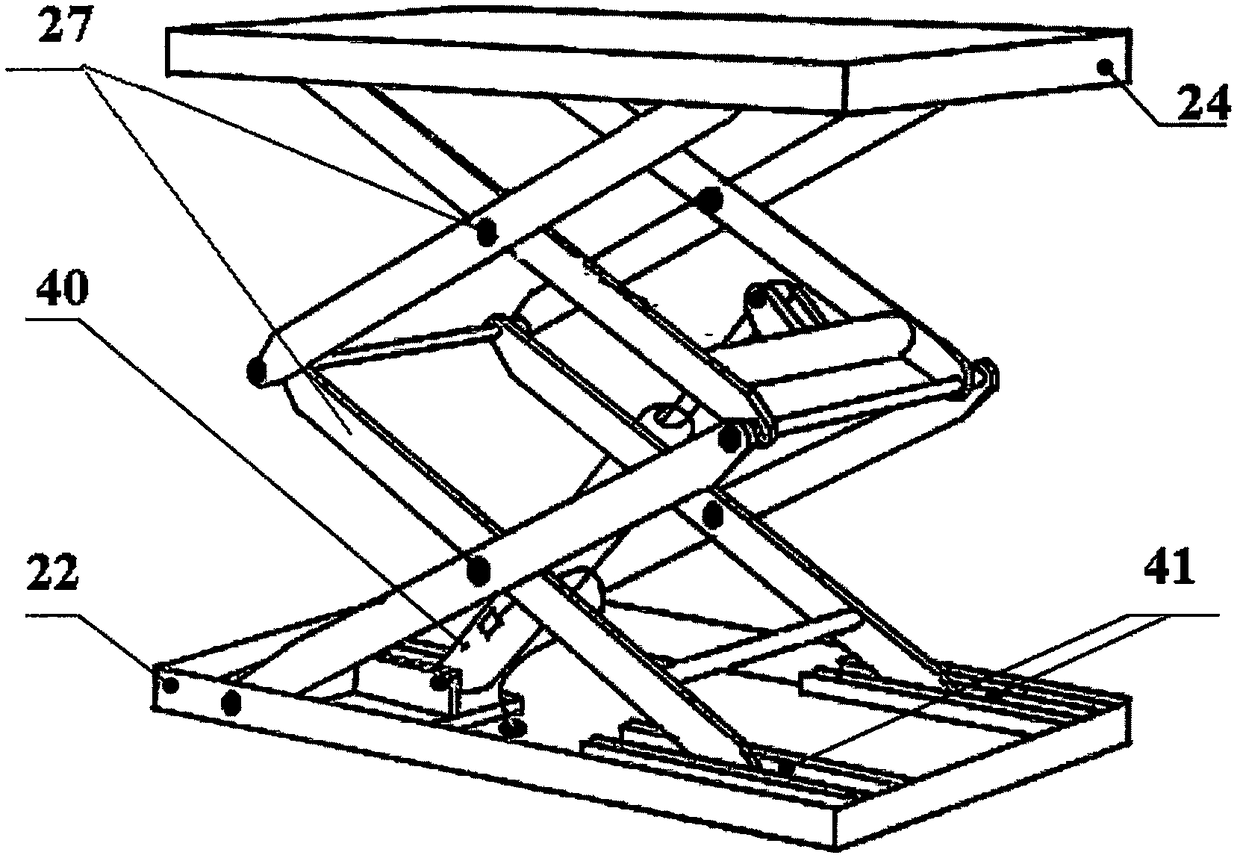

[0030] Such as figure 1 As shown, after the truck 28 drives to the desired site, in order to prevent the site from being rough, the hydraulic system c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com