Scale breaking roll with dust suction function for cold rolling pickling line

A technology of cold-rolling acid and scale-breaking rolls, which is applied in metal rolling, dust removal, metal rolling, etc., and can solve problems affecting the surface quality of strip steel, the difficulty and pressure of dust removal in subsequent processes, and unfavorable health of operators, etc. , to achieve the effect of simple structure, convenient installation and effective dust collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

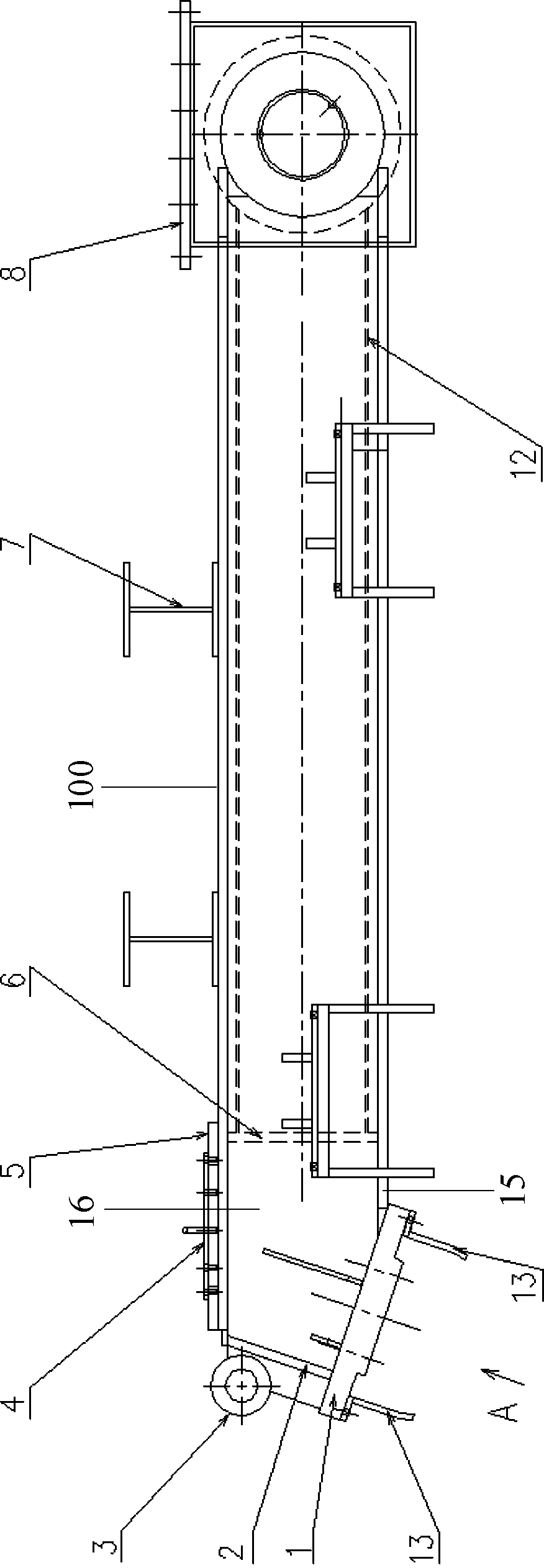

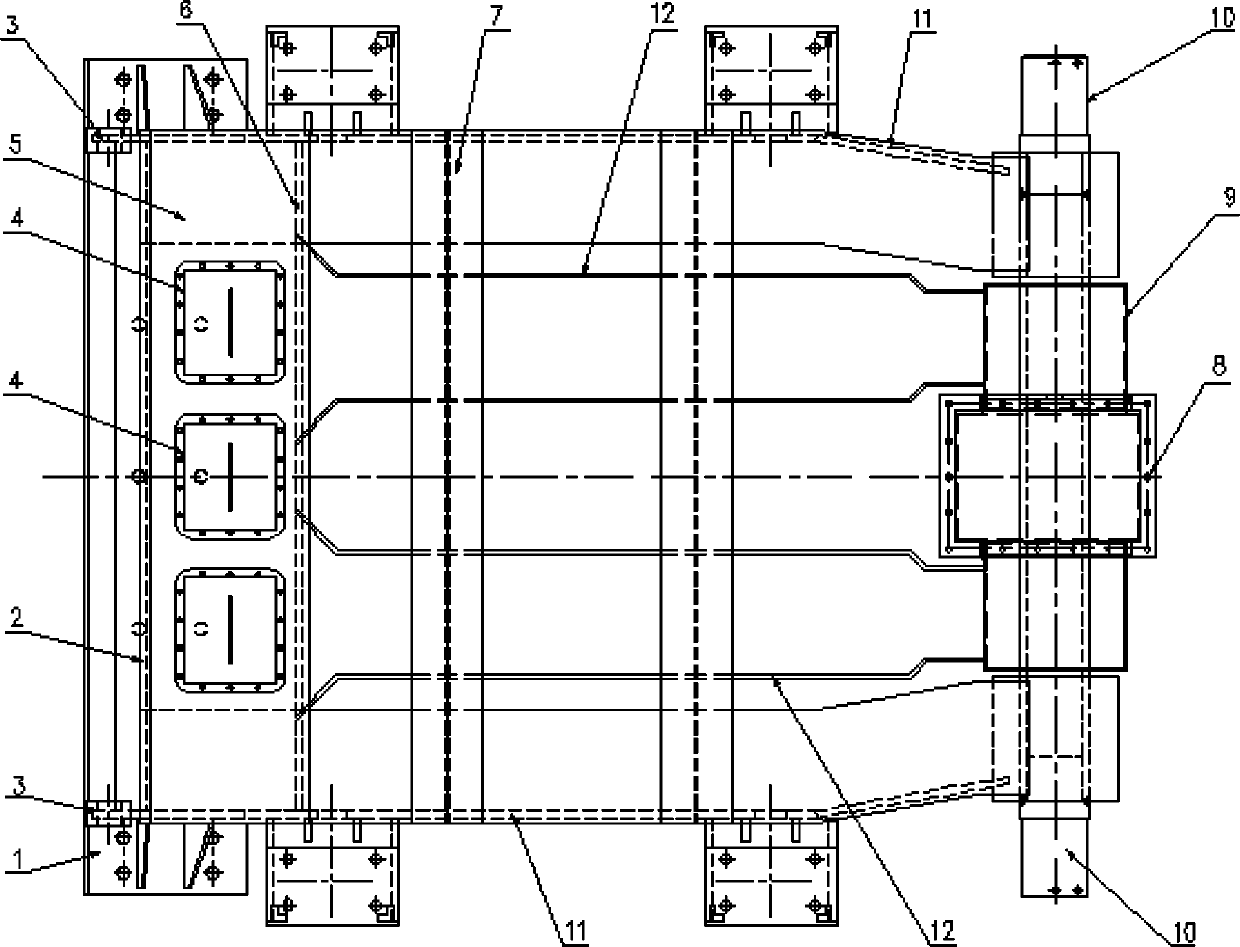

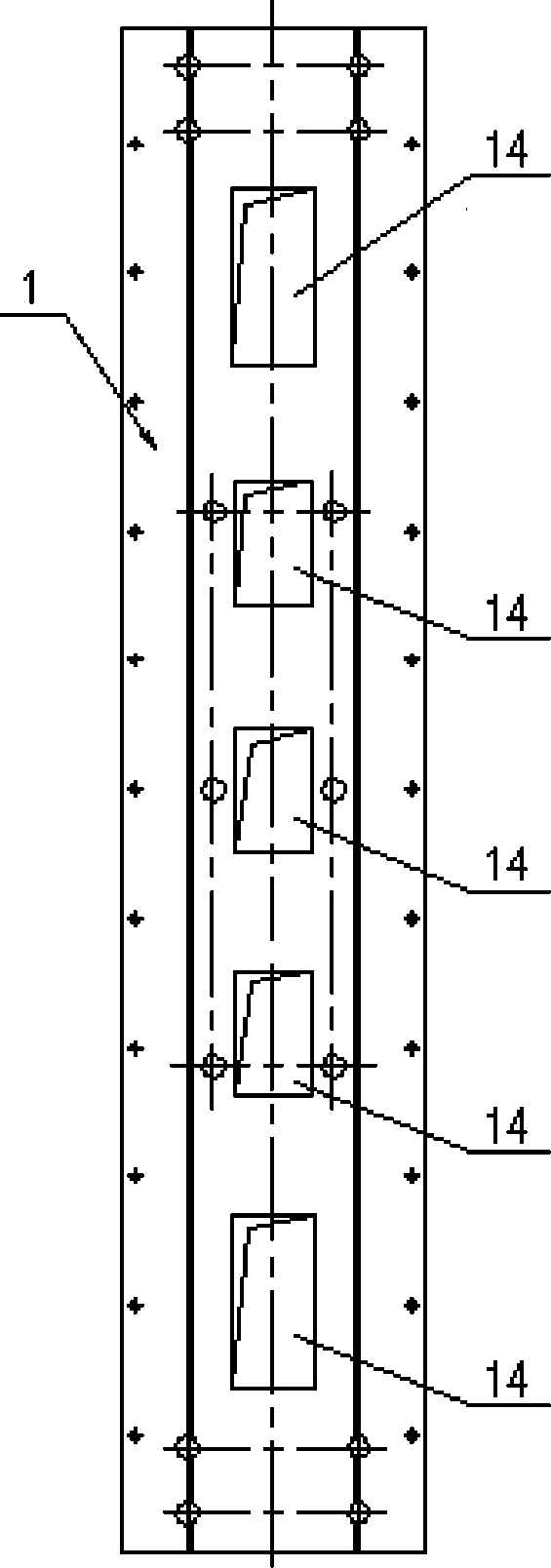

[0025] A scale-breaking roll with dust suction function for cold rolling pickling line, including swing arm 100 and roll box 200, such as Figure 1 ~ Figure 6 As shown, the specific structure is:

[0026] Such as Figure 1 ~ Figure 3 Shown: the swing arm 100 includes a front bottom plate 1, an outer sealing plate 2, a lifting lug 3, a top cover plate 5, an inner sealing plate 6, a shaft sleeve air outlet 8, a shaft sleeve 9, a rotating shaft 10, a support frame 11, and a wind guide pipe 12. Front wind deflector 13, bottom cover 15 and side cover 16;

[0027] A support frame 11 is provided on both sides of the swing arm 100. The rear end of the support frame 11 is sleeved and fixed on the shaft 10, the sleeve 9 is sleeved and fixed on the shaft 10, and the sleeve 9 is provided on the two support frames Between 11, the shaft sleeve air outlet 8 adopts a copper sleeve and is rotatably sleeved in the middle of the shaft sleeve 9, and the inner cavity of the shaft sleeve 9 and the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com