Ultrasonic Assisted Amorphous Alloy Punching and Forming Method

A technology of amorphous alloy and forming method, which is applied in the field of ultrasonic-assisted amorphous alloy punching and forming, can solve problems such as uneven stamping force, achieve the effects of improving stamping stability, improving the quality of processed products, and increasing the speed of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

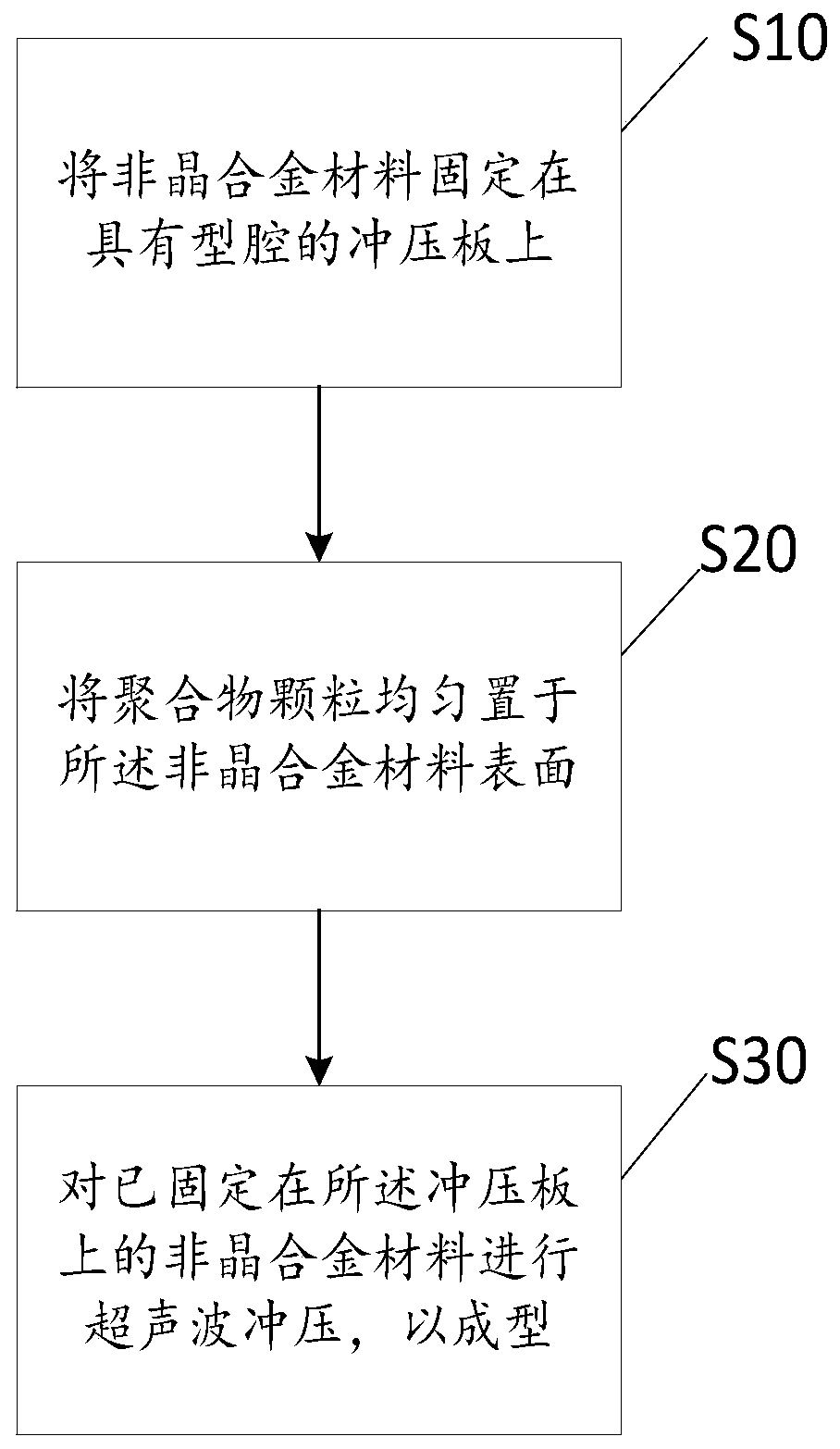

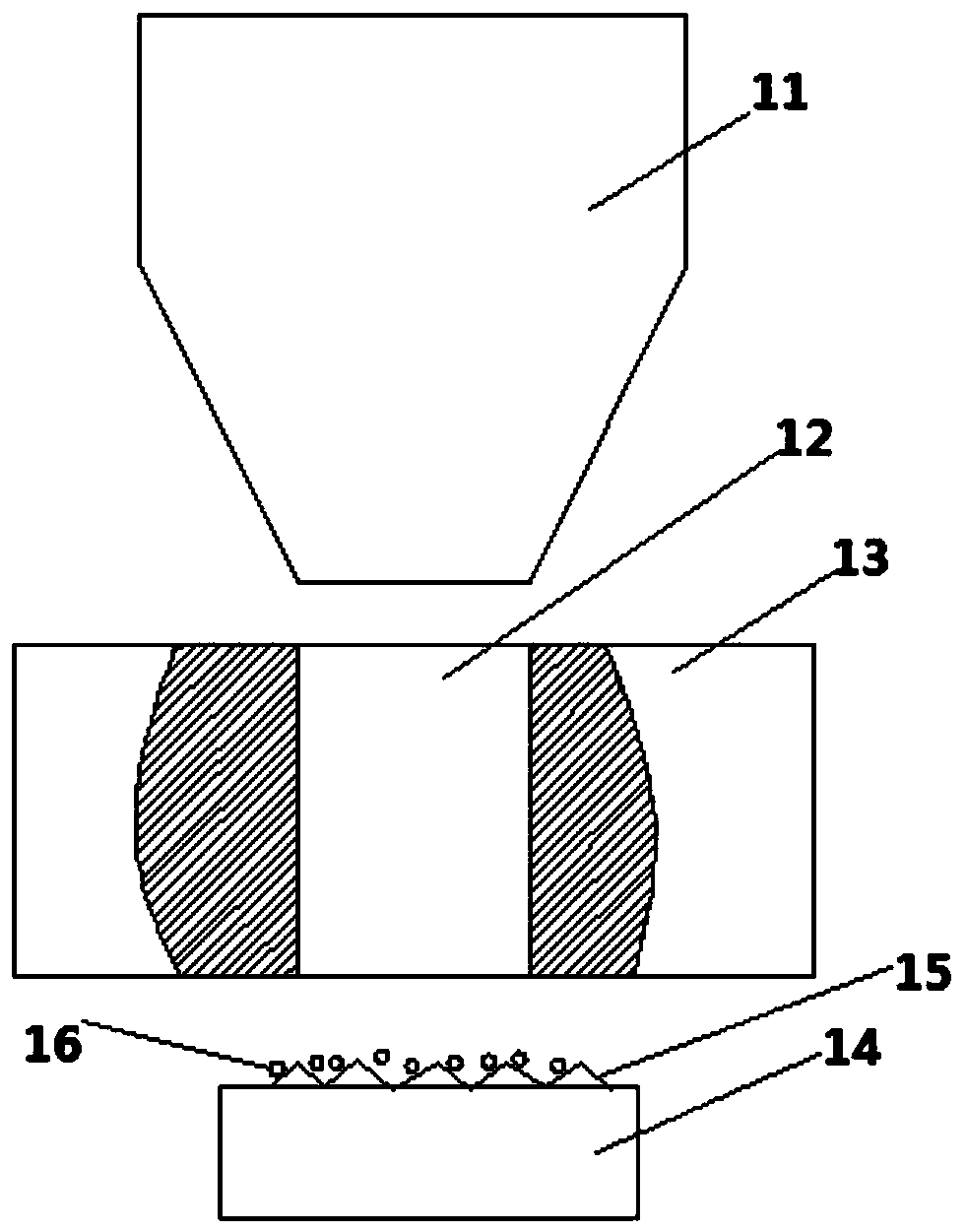

[0023] refer to figure 1 , figure 1 It is a schematic flow chart of the first embodiment of the present invention.

[0024] Such as figure 1 As shown, the ultrasonic-assisted amorphous alloy blanking forming method of the present invention comprises the following steps:

[0025] Step S10, fixing the amorphous alloy material on a stamping plate with a cavity;

[0026] In the present invention, the blanking forming method is a process of using an ultrasonic stamping device to punch an amorphous alloy strip or plate to obtain parts of the designed shape and size; in step S10, in order to ensure subsequent processing of all During the stamping process of the amorphous alloy, it is necessary to fix the amorphous alloy to avoid movement to cause stamping failure, and fix the amorphous alloy on the stamping plate; the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com