Improved double-barrel stamping mechanism for robot

A stamping mechanism and robot technology, applied in the field of robots, can solve the problems of not being able to realize multi-angle stamping, double-row stamping, affecting work efficiency, and not being able to local lighting, etc., to achieve high stamping stability, improve work efficiency, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

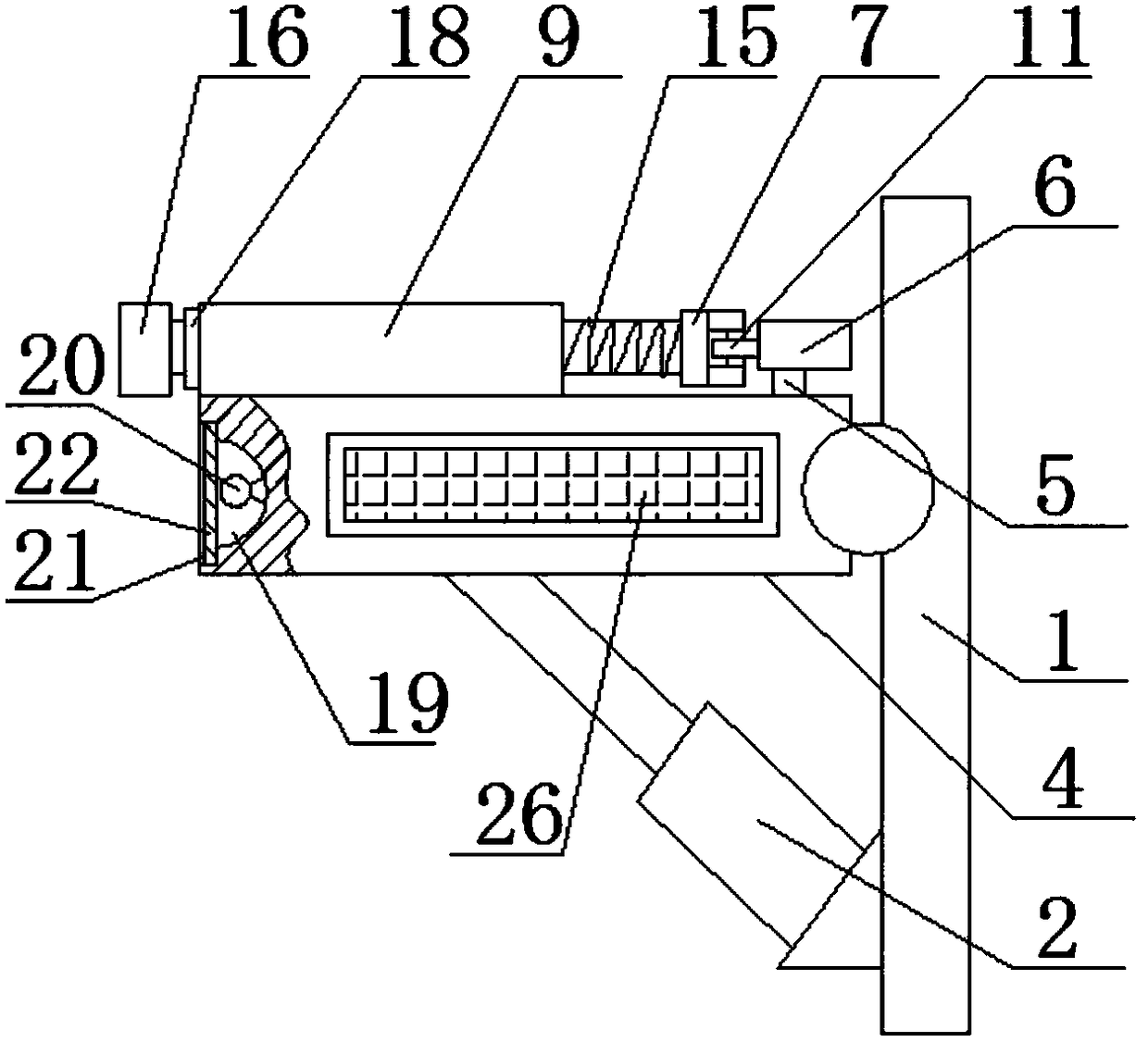

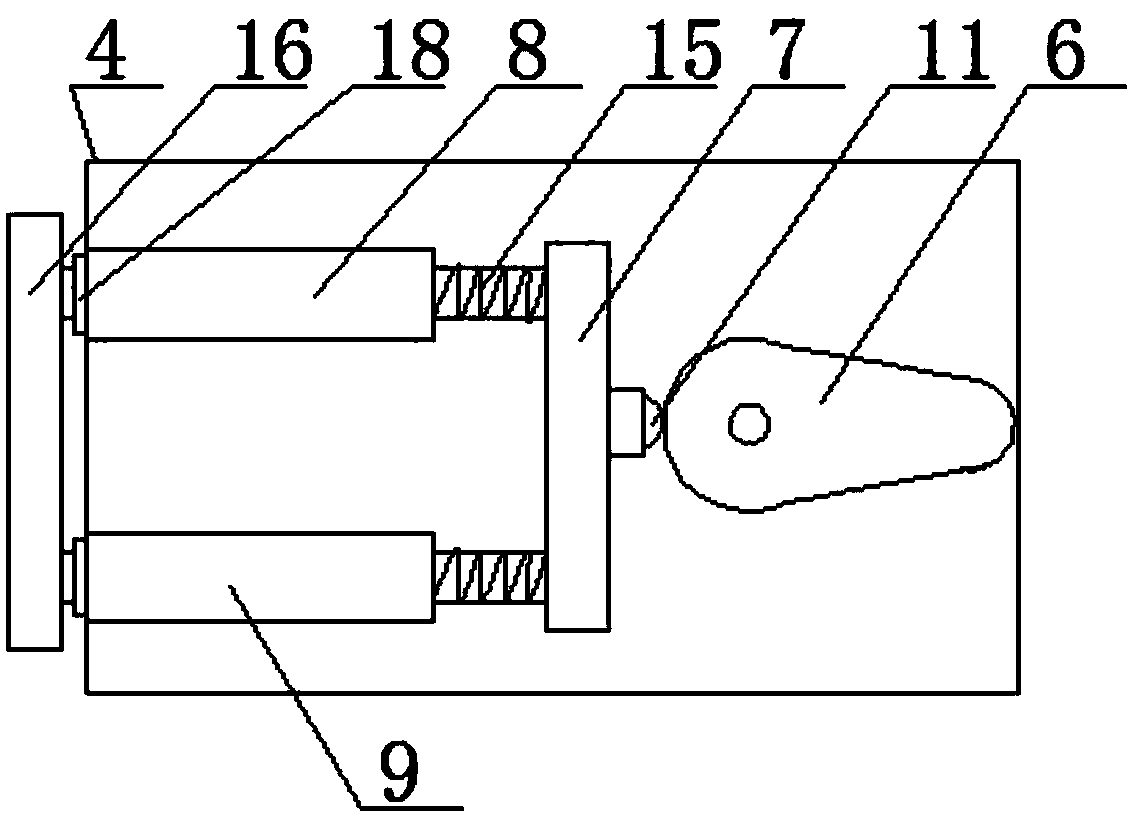

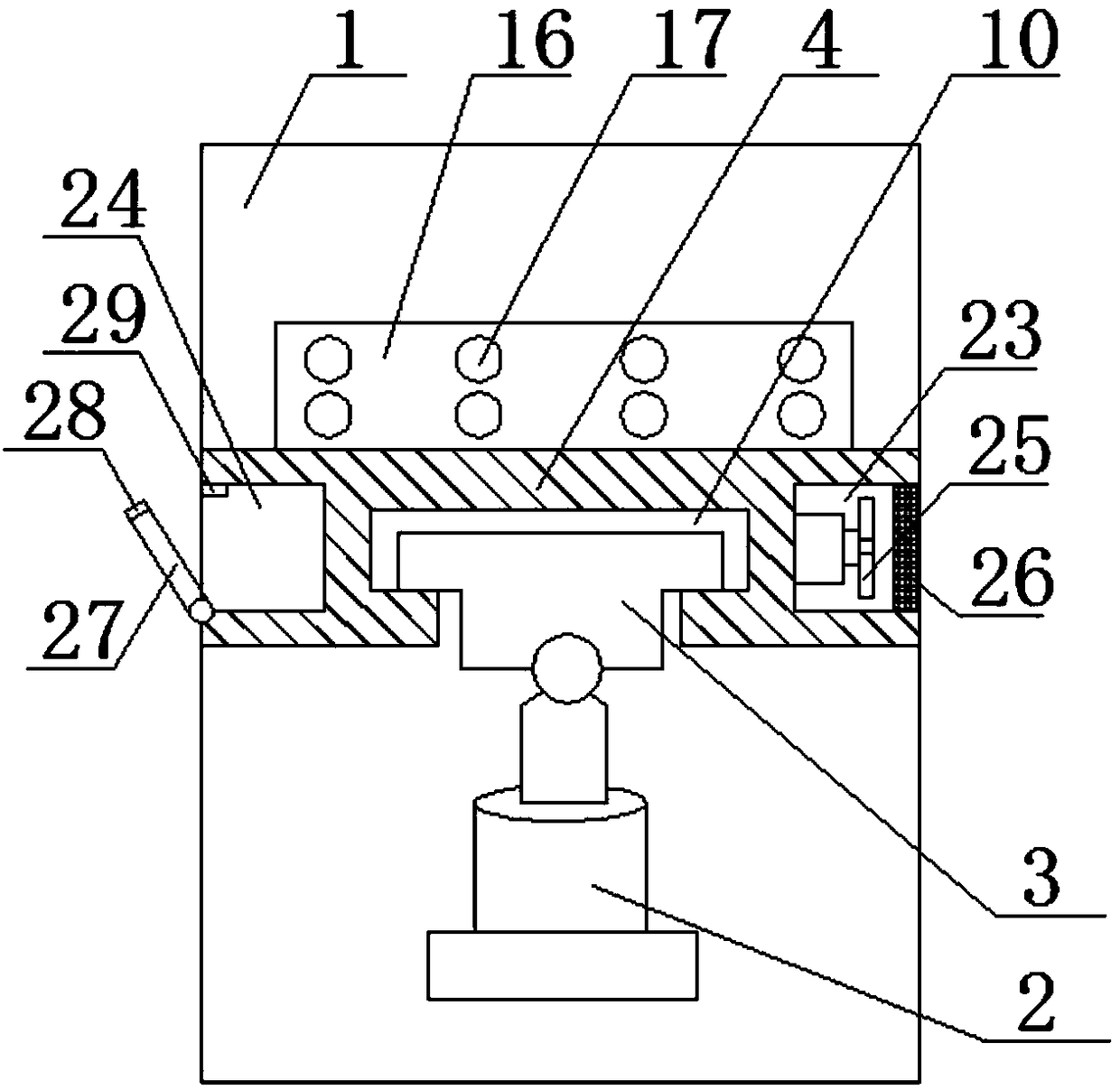

[0036] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0037] Such as Figures 1 to 4 As shown, an improved double-tube punching mechanism for a robot includes a mounting plate 1, a hydraulic cylinder 2, a slider 3, a punching platform 4, a servo motor 5, a cam 6, a double punching rod 7, a first punching cylinder 8 and a second punching cylinder. Two stamping cylinders 9; the right side wall of the mounting plate 1 is fixedly connected to the frame, the left side is fixedly connected to the fixed end of the hydraulic cylinder 2, the moving end of the hydraulic cylinder 2 is hinged to the slider 3, and the hydraulic pressure The cylinder 2 is arranged obliquely upward; the right side of the stamping platform 4 is connected to the left side of the mounting plate 1 through hinge rotation, the stamping platform 4 is arranged above the hydraulic cylinder 2, and the bottom end of the stamping platform 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com