Double-pipe punching mechanism for protective robot

A technology of stamping mechanism and robot, applied in the field of robots, can solve the problems of not having the automatic detection function of human body protection function, unable to realize multi-angle stamping, double-row stamping, unadjustable stamping area, etc., so as to improve safety performance and stamping stability. High and extended punching range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

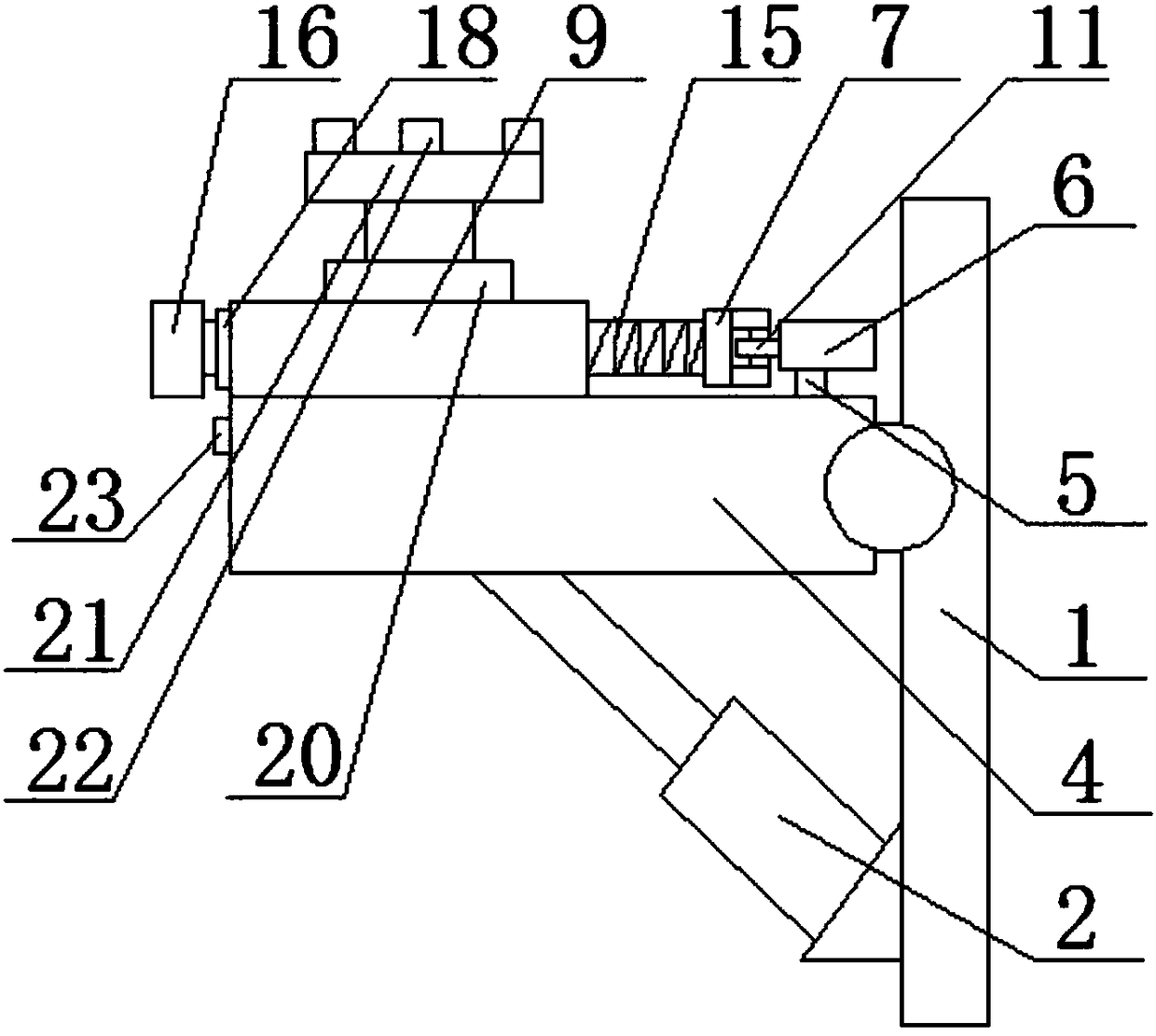

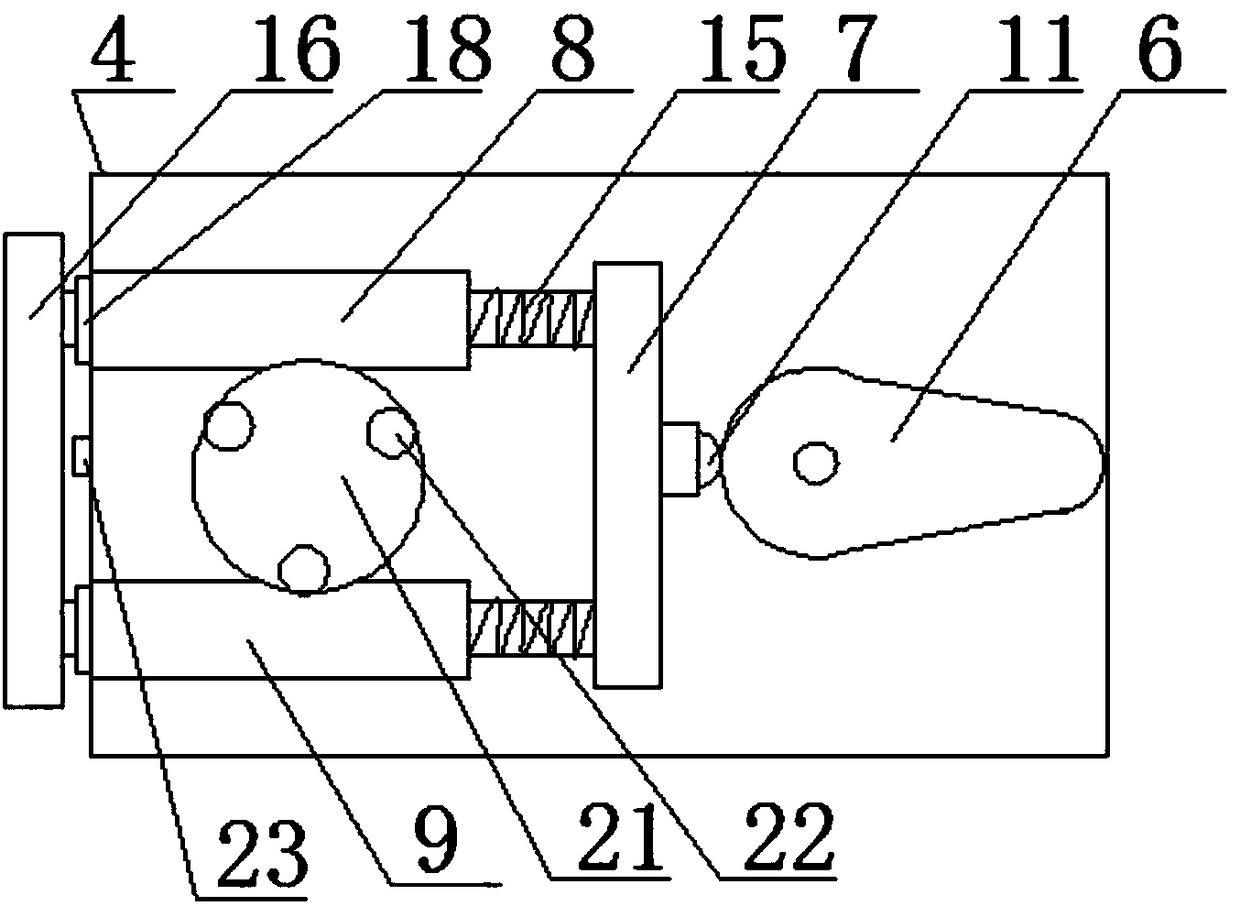

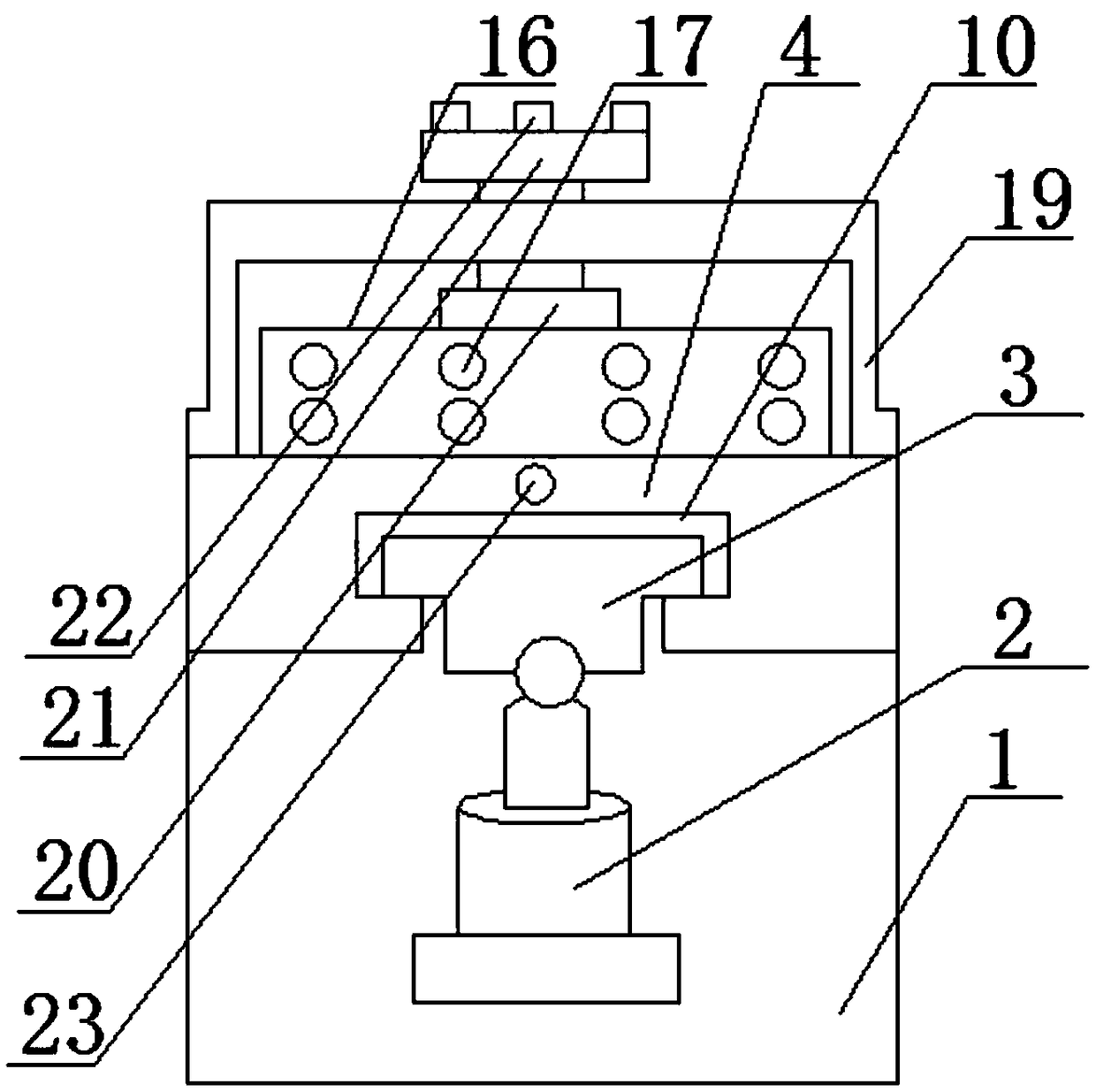

[0035] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0036] Such as Figures 1 to 4 As shown, a double-tube stamping mechanism for a protective robot includes a mounting plate 1, a hydraulic cylinder 2, a slider 3, a stamping platform 4, a servo motor 5, a cam 6, a double stamping rod 7, a first stamping cylinder 8 and a second stamping cylinder. Two stamping cylinders 9; the right side wall of the mounting plate 1 is fixedly connected to the frame, the left side is fixedly connected to the fixed end of the hydraulic cylinder 2, the moving end of the hydraulic cylinder 2 is hinged to the slider 3, and the hydraulic pressure The cylinder 2 is arranged obliquely upward; the right side of the stamping platform 4 is connected to the left side of the mounting plate 1 through hinge rotation, the stamping platform 4 is arranged above the hydraulic cylinder 2, and the bottom end of the stamping platform 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com