Floating point pressure module and working mode thereof

A floating, point-pressing technology, applied in lamination auxiliary operations, lamination, lamination devices, etc., can solve problems such as product overpressure, high processing cost, troublesome pressing plate replacement, etc., to improve stamping stability and guarantee Consistent force, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

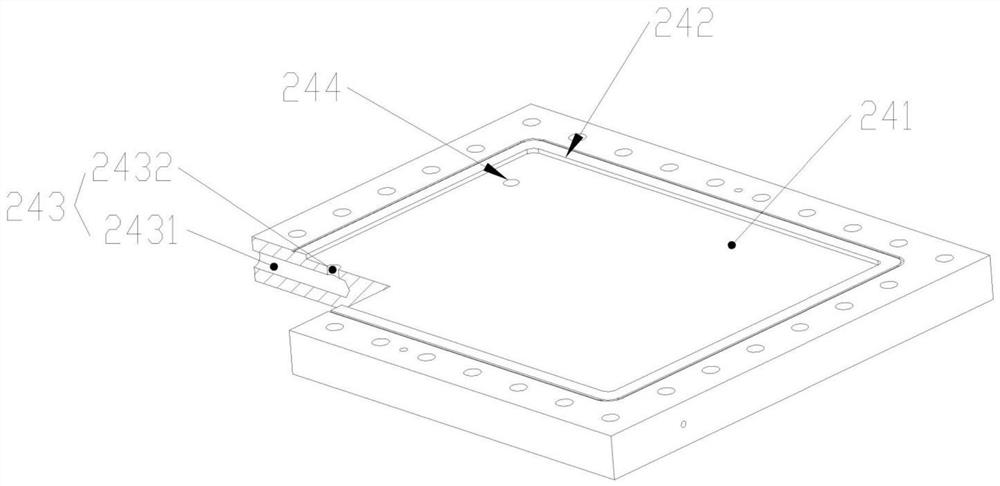

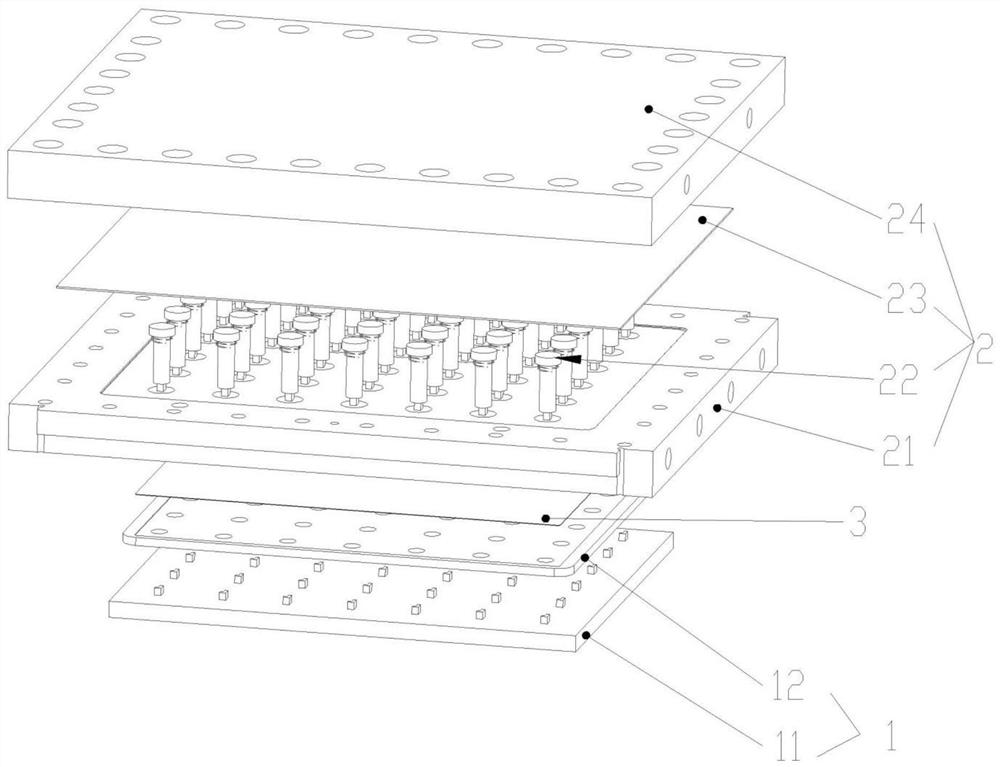

[0039] like figure 1 Shown is an exploded perspective view of the present invention, including a lower die structure 1, an upper die structure 2, and the upper die structure 2 is arranged directly above the lower die structure 1; wherein, the upper die structure 2 includes an upper die guide plate 21, a punch The head structure 22, the floating soft plate 23, the upper die air inlet plate 24, the punch structure 22 has several groups, which are arranged in parallel on the upper die guide plate 21, and the floating soft plate 23 is arranged above the punch structure 22, And its four side edges are fixed by the upper mold air inlet plate 24 and the upper mold guide plate 21 arranged vertically.

[0040] The floating soft plate 23 is made of heat-resistant rubber.

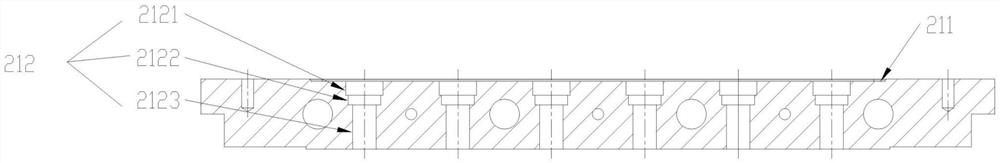

[0041] like figure 2 and as image 3 Shown are a perspective view and a cross-sectional view of the upper die guide plate 21 , which is provided with a first floating groove 211 , and the size of the first floatin...

Embodiment 2

[0050] The floating point pressing module in this embodiment includes a lower mold structure 1 and an upper mold structure 2, and the upper mold structure 2 is disposed directly above the lower mold structure 1; wherein, the upper mold structure 2 includes an upper mold guide plate 21, The punch structure 22 , the floating soft plate 23 , and the upper die air inlet plate 24 . The punch structure 22 has 42 groups, which are arranged on the upper die guide plate 21 at equal intervals in the form of 7 rows×6 columns. The plate 23 is arranged above the punch structure 22, and its four side edges are fixed by the upper die air inlet plate 24 and the upper die guide plate 21 arranged vertically.

[0051] In the present invention, the floating soft plate 23 is made of silica gel.

[0052] The upper die guide plate 21 is provided with a first floating groove 211 , and the size of the first floating groove 211 is smaller than that of the floating soft plate 23 . The upper die guide p...

Embodiment 3

[0069]There are several groups of floating point pressure modules in this embodiment, which are arranged side by side according to requirements, including a lower mold structure 1 and an upper mold structure 2, and the upper mold structure 2 is arranged directly above the lower mold structure 1; The die structure 2 includes an upper die guide plate 21, a punch structure 22, a floating soft plate 23, and an upper die air inlet plate 24. The punch structures 22 have several groups and are arranged on the upper die guide plate 21 in parallel. The soft plate 23 is arranged above the punch structure 22, and its four side edges are fixed by the upper die air inlet plate 24 and the upper die guide plate 21 arranged vertically. According to the requirements of the pressing position on the FPC board, several floating point pressing modules can be used for simultaneous pressing. Each group of floating point pressing modules is provided with a certain number of stamping structures 22, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com