Metal tube end grinding device

A metal pipe and end technology, which is applied in the field of metal pipe end grinding devices, can solve the problems of sparks splashing into workers, easily scratching workers, and heavy labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

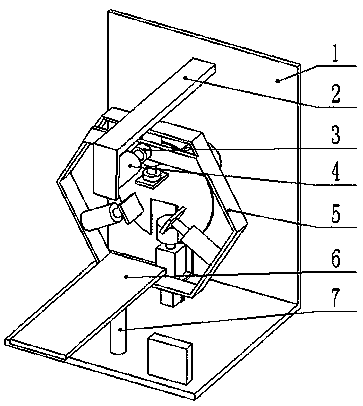

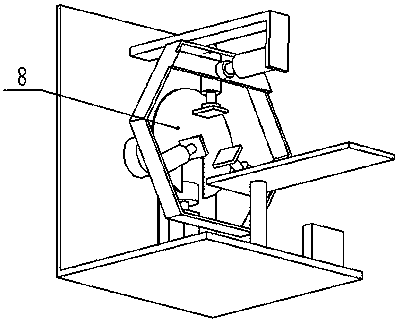

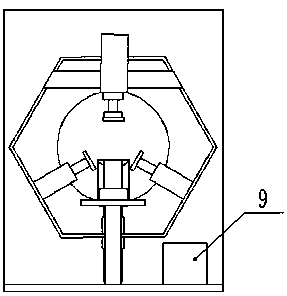

[0018] The present invention is achieved through the following technical solutions: a metal pipe end grinding device, including a workbench 1, a first bracket 2, a first pressure sensor 3, a first hydraulic cylinder 4, a fixing device 5, a support table 6, a second Support 7, grinding device 8 and controller 9, described workbench 1 is L-shaped structure, and described first support 2 is fixed on the side baffle plate of workbench 1, and it is parallel with the iron plate at the bottom end of workbench 1, so The first pressure sensor 3 is installed between the first hydraulic cylinder 4 and the fixing device 5, through which the pressure of the first hydraulic cylinder 4 is detected, and when the pressure is too large, the first hydraulic cylinder 4 stops pressurizing and starts to limit Function, the first hydraulic cylinder 4 is fixed on the first bracket 2, which is parallel to the ground, and its main shaft is connected with the fixing device 5, and the metal pipe clamped b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap